H-3000 Portable Hardness Tester with Printer

With a built-in printer, the H-3000 portable hardness tester supports printing measured data on the spot, which is conducive to storage. Due to attractive price and high performance, this sclerometer is well received by customers. It is able to quickly and accurately measure the hardness of big and hard metallic materials. The hardness tester realizes automatic conversion of hardness system, such as Rockwell, Brinell, Vickers, Shore and so on.

Features

1. The hardness testing machine is easy to operate through its keyboard.

2. The hardness tester makes use of an automatic identification impact device and a large LCD screen with backlight.

Technical Parameters

1. Test precision: /-0.5% actual hardness

2. Repeatability of indicating value: /-4HL

3. Measuring range: 200-960HL

4. Minimum thickness: <1.27cm(steel)

5. Measurable materials: Steel, cast steel, alloy tool steel, stainless steel, grey cast iron, nodular cast iron, cast aluminum, brass, bronze, copper alloy

6. Battery: 6V nickel-metal hydride battery

7. USB output

8. Automatic conversion of hardness system: Brinell, Rockwell B & C, Vickers and Shore

9. Automatic displaying mean, minimum and maximum values

10. Upper and lower limit setting with alarm

11. Electric quantity indication

12. Data storage: 500 sets

13. Charger: 9V/500mA

14. Continuous working period: About 150 hours (with backlight off and without printing)

15. Printing paper

1) Width: 57.5±0.5mm

2) Diameter: 30mm

16. Communication interface: USB1.1

17. Working environment: -15-40℃

18. Dimension: 212x80x32mm

19. Weight: 245g

Links:https://www.globefindpro.com/products/79034.html

-

F-2100 Digital Force Gauge

F-2100 Digital Force Gauge

-

Heat Pump Incense Dryer

Heat Pump Incense Dryer

-

HRRS-150 Dual-purpose Rockwell Hardness Tester

HRRS-150 Dual-purpose Rockwell Hardness Tester

-

V-2000 Digital Vibration Meter

V-2000 Digital Vibration Meter

-

Microwave Ceramic Sintering Furnace

Microwave Ceramic Sintering Furnace

-

EZB Series Borescope

EZB Series Borescope

-

DHV-2101 Digital Vickers Hardness Tester

DHV-2101 Digital Vickers Hardness Tester

-

Cylinder Tube

Cylinder Tube

-

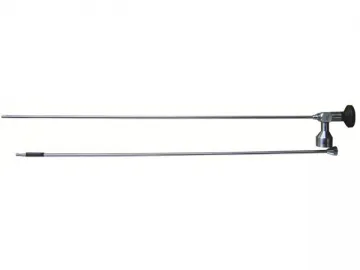

B-2000 Rigid Borescopes

B-2000 Rigid Borescopes

-

V-1000 Pocket Vibration Meter

V-1000 Pocket Vibration Meter

-

Single Action Hydraulic Cylinder

Single Action Hydraulic Cylinder

-

HSA-2,HSD-2 Digital Shore Durometer

HSA-2,HSD-2 Digital Shore Durometer