HB-3000 Digital Brinell Hardness Tester

The HB-3000 digital Brinell hardness tester adopts electronic closed loop design, which contributes to light weight and accurate measurement. Its outstanding software design facilitates operation and guarantees high performance.

The hardness tester makes use of Brinell hardness measurement principle, and is appropriate for unhardened steel, cast iron, nonferrous metal, soft bearing alloy and other materials. Its maximum test force reaches up to 3000kgf. The Brinell hardness test may create deep indentation that will not influenced by microstructural segregation, large crystal grain or uneven components of specimens. Therefore, the measuring instrument is able to exactly measure the hardness of cast iron, cast steel, forged steel and other materials with coarse grains. Compared with general portable durometers, it successfully avoids errors.

Features

1. The hardness tester is provided with fine machinery structure and microcomputer close loop control system, which ensures precision control over test force. It leaves out traditional weight loading steps.

2. Controlled by a microcomputer, it automatically loads, dwells and unloads.

3. There are 10 grades of test force. The operator can switch the test force through the button.

4. Its high brightness LCD can clearly display test parameters, including test force, duration time, indenter kinds, operation tips and other information.

5. Its weight is 50% lighter than that of many like products.

6. It does not require the operator to move weights, considerably reducing his labor intensity and eliminates potential safety hazard.

7. The 20X reading microscope is able to correctly read indentation diameter.

8. The hardness tester innovatively has hardness calculation function, so as to intelligently calculate hardness values.

Technical Parameters

1. Test force: 3000kgf (29400N), 1500Kgf (14700N), 1000Kgf (9800N), 750Kgf (7355N), 500Kgf (4900N), 250Kgf (2452N), 187.5Kgf (1839N), 125Kgf (1226N), 100Kgf (980N), 62.5Kgf (612.9N)

2. Test force precision: 0.5% (1% higher than national standard requirements)

3. Holding time of test force: 2~99 seconds (settable)

4. Diameter of tungsten carbide ball indenter: 10mm, 5mm, 2.5mm

5. Measuring range: 3.18~653HBW

6. amplification factor of reading microscope: 20X

7. Resolution capability of reading microscope: 0.005mm

8. Hardness Brinell Wolframkarbid (HBW) Indication error% Repeatability of indicating value%

1) ≤ 125 ± 3.0 ≤ 3.0

2) 125 < HBW ≤ 225 ± 2.5 ≤ 2.5

3) > 225 ± 2.0 ≤ 2.0

9. Maximum measurable height: 230mm

10. Max measurable depth: 140mm

11. Dimension: 530mm×260mm×750mm

12. Power supply: Single phase, AC, 110V/220V, 50~60Hz, 4A

13. Net weight: 110kg

Links:https://www.globefindpro.com/products/79067.html

-

Colour Meter

Colour Meter

-

CT-1000 Coating Thickness Gauge with Built-In Probe

CT-1000 Coating Thickness Gauge with Built-In Probe

-

HSA,HSD Digital Shore Durometer

HSA,HSD Digital Shore Durometer

-

GM-2000 Multi Angle Gloss Meter

GM-2000 Multi Angle Gloss Meter

-

TB Series Fibre Optic Borescope

TB Series Fibre Optic Borescope

-

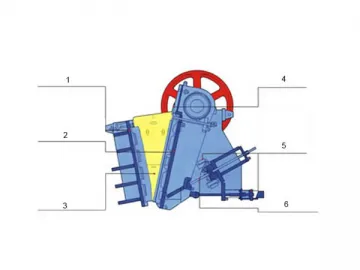

Z Series Jaw Crusher

Z Series Jaw Crusher

-

Two Way Articulating Borescope

Two Way Articulating Borescope

-

T-4000 Precision Ultrasonic Thickness Gauge

T-4000 Precision Ultrasonic Thickness Gauge

-

R-1000 Surface Roughness Tester

R-1000 Surface Roughness Tester

-

F-1100 Analogue Force Gauge

F-1100 Analogue Force Gauge

-

B-1000 Rigid Borescopes

B-1000 Rigid Borescopes

-

ADHR-150 Digital Rockwell Hardness Tester

ADHR-150 Digital Rockwell Hardness Tester