Z Series Jaw Crusher

Overview

The Z series jaw crusher is the new-type crushing equipment YUANNAI manufactures. It comes with V type chamber and thereby its crushing capability is improved by 15-20% in comparison with similar product with common chamber.

This feldspar crusher not only suits for crushing limestone, medium hard iron ores and feldspar, but also enables to crush aggregates as well as dry and wet artificial sands. As a multi-purpose machine, our jaw crusher also comes with optional extras to meet your demands.

Working Principle

The upper part of movable jaw is in circular motion via rotation of eccentric shaft situated between lining plate and movable jaw. This elliptic motion triggers toggle plate to push movable jaw to move forwards and backwards. Once the movable jaw moves forth toward fixed jaw, materials will be squashed or chopped in crushed chamber.

The crushed chamber of this limestone crusher performs crushing under the action of fixed jaw plate secured to machine rack and movable jaw plate installed on the movable jaw. After utter crushing, materials will be discharged out of machine.

Features

Pictures of hydraulic adjustment station

1.Jaw crusher

2.Grease lubrication station

3.Hydraulic adjustment station

1. The “V” type crushing chamber has an opening size equal to the nominal opening size (a common jaw crusher uses a traditional asymmetric crushing chamber structure, which has a smaller, less effective opening), so the holding capacity is increased by15-20%.

2. The discharge gate uses an advanced hydraulic adjusting device. Cavity and motion parameters increase the material’s ability to be fed quickly and efficiently through the machine.

3. The jaw crusher is made from superior manganese steel and thick steel plates. We rigorously test the mechanical properties to ensure that the jaw crusher can handle heavy loads and be resistant to large impact.

4. The jaw crusher is equipped with a double wedge discharge adjusting system, which is easy, safe, and fast. The discharge gate can be adjusted manually within a few minutes by using the accompanying tools we provide with the crusher. There’s no need to handle the dirty shim.

5. A fixed jaw plate and swing jaw plate are interchangeable, for a more convenient and space-efficient design.

Parameters

| Model | Z80 | Z100 | Z96 | Z106 | Z116 | Z110 | Z125 | Z140 | |

| Material inlet width(mm) | 800 | 1000 | 930 | 1060 | 1150 | 1100 | 1250 | 1400 | |

| Material inlet depth(mm) | 510 | 760 | 580 | 700 | 800 | 850 | 950 | 1070 | |

| Motor power (KW) | 75 | 110 | 90 | 110 | 132 | 160 | 160 | 200 | |

| Rotating speed (rpm) | 350 | 260 | 330 | 280 | 260 | 230 | 220 | 220 | |

| Product size(mm) | Tight side(mm) | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h |

| 0-30 | 20 | ||||||||

| 0-35 | 25 | ||||||||

| 0-45 | 30 | ||||||||

| 0-60 | 40 | 65-85 | |||||||

| 0-75 | 50 | 80-95 | |||||||

| 0-90 | 60 | 95-125 | 120-155 | ||||||

| 0-105 | 70 | 115-150 | 150-210 | 140-180 | 155-200 | 170-220 | 190-250 | ||

| 0-120 | 80 | 130-170 | 170-225 | 160-210 | 175-230 | 190-250 | 210-275 | ||

| 0-135 | 90 | 150-195 | 190-245 | 180-235 | 200-260 | 215-280 | 235-305 | ||

| 0-150 | 100 | 165-215 | 215-280 | 200-260 | 220-290 | 240-310 | 255-330 | 290-380 | |

| 0-185 | 125 | 210-275 | 265-345 | 250-325 | 280-365 | 295-385 | 310-405 | 350-455 | 385-500 |

| 0-225 | 150 | 250-325 | 315-410 | 300-390 | 335-435 | 350-455 | 370-480 | 410-535 | 455-590 |

| 0-260 | 175 | 290-380 | 370-480 | 350-455 | 390-510 | 405-525 | 425-550 | 470-610 | 520-675 |

| 0-300 | 200 | 420-545 | 445-580 | 460-600 | 480-625 | 530-690 | 590-765 | ||

| 0-340 | 225 | 590-770 | 655-850 | ||||||

| 0-375 | 250 | 650-845 | 725-945 | ||||||

Notes

1. The data in the above table is obtained according to actual service conditions of our jaw crusher.

2. Generally, small discharge gate with tight side can be used. Please contact our engineers for specific application performance.

3. The output data in the table is tenable under the conditions as below:

a. Specific gravity of materials is 2.7t/m3.

b. Feedstocks can smoothly enter crushing chamber.

c. Bridging phenomenon won't occur.

4. Output may vary with feeding mode and material characteristics as grain composition, water or silt content, bulk density and crushability.

5. The inspection method of discharge gate with tight side varies with jaw plate tooth form.

6. To realize optimal crushing performance, the jaw crusher should be operated under following conditions:

a. Proper jaw plate

b. Appropriate granular composition of feedstocks

c. Controllable feedstock quantity

d. Strong feeding capability and sufficient feeding width

e. Ample material discharging area

f. Matched belt conveyor

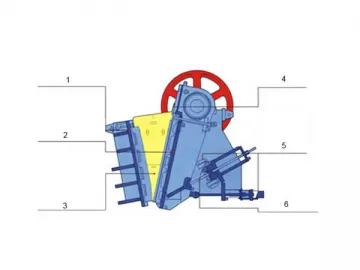

Structure Chart:

1.Swing jaw plate press block

2.Swing jaw plate

3.Fixed jaw plate press block

4.Upper side plate

5.Lower side plate

6.Fixed jaw plate

7.Wear-resistant side plate

8.Main bearing

9.Belt pulley

10.Toggle plate

11.Toggle plate seat

12.Spring rod

13.Spring

1.Solid and reliable high-strength frame

2.Swing jaw plate that prevents horizontal deviation

3.Compared with a common crusher chamber, this chamber’s capacity is increased by 15-20%

4.Impact absorptive discharging plate

5.Convenient, fast and efficient hydraulic adjusting device for discharging

6.Toggle plate that prevents horizontal deviation

Application Field:

Links:https://www.globefindpro.com/products/79073.html

-

PFX Series Impact Crusher

PFX Series Impact Crusher

-

YNKS Series Jaw Crusher

YNKS Series Jaw Crusher

-

XL Series Washing and Dewatering Screw

XL Series Washing and Dewatering Screw

-

Mobile Jaw Crusher

Mobile Jaw Crusher

-

ISP Series Impact Crusher

ISP Series Impact Crusher

-

Compound Crusher Parts

Compound Crusher Parts

-

TB Series Fibre Optic Borescope

TB Series Fibre Optic Borescope

-

GM-2000 Multi Angle Gloss Meter

GM-2000 Multi Angle Gloss Meter

-

HSA,HSD Digital Shore Durometer

HSA,HSD Digital Shore Durometer

-

CT-1000 Coating Thickness Gauge with Built-In Probe

CT-1000 Coating Thickness Gauge with Built-In Probe

-

Colour Meter

Colour Meter

-

HB-3000 Digital Brinell Hardness Tester

HB-3000 Digital Brinell Hardness Tester