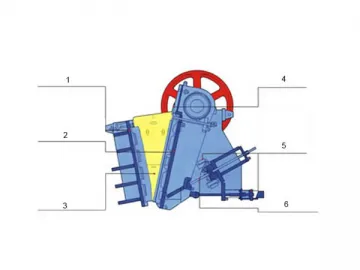

YNKS Series Jaw Crusher

Overview

The YNKS series jaw crusher in double toggle type is made by introducing advanced technology from Japan. With production capacity of 7-380t/h and feedstock particle size of 210-770mm, this double toggle jaw crusher is well suited for crushing materials with compressive strength of less than 300MPa, such as limestone, calcium carbide, acetylene sludge, shale, basalt, cobble, bluestone, iron ore, copper ore, steel slag, etc. Presently, it has been widely used in mining, building material, highway, hydroelectric, and chemical engineering industries.

Features

1. This jaw crusher works under power of 15KW-160KW, featured by high stability, small vibration, small noise and environment optimization.

2. Less dust is produced during operation.

3. The quick-wear parts of our calcium carbide crusher are robust and durable, coming with extra long service life.

4. Lubricating system is safe and reliable with small maintenance load. Meanwhile, component replacement is very convenient.

5. Crushing chamber is deep without dead zone, largely improving feeding capability and production output.

6. Our crushing machine is also designed with gasket type discharge gate adjusting device for dependable and easy operation.

Parameters

| Model | Discharging gate size (mm) | Max. feeding size (mm) | Discharging gate adjusting range(mm) | Production capacity (t/h) | Motor power (KW) | Weight (kg) |

| YNKS1610 | 400×250 | 210 | 20-80 | 7-23 | 15 | 2634 |

| YNKS2416 | 600×400 | 340 | 40-100 | 25-64 | 30 | 5860 |

| YNKS3020 | 760×500 | 425 | 50-120 | 40-86 | 55 | 9700 |

| YNKS3624 | 920×600 | 510 | 65-130 | 88-170 | 75 | 16400 |

| YNKS4230 | 1060×750 | 640 | 65-200 | 90-310 | 110 | 23500 |

| YNKS4836 | 1220×910 | 770 | 75-220 | 115-380 | 160 | 37400 |

| YNKS5112 | 1300×300 | 240 | 20-90 | 18-110 | 75 | 11060 |

| YNKS4816 | 1200×400 | 320 | 25-90 | 18-80 | 55 | 9950 |

1.Feeding

2.Crushing chamber

3.Space

4.Discharge opening

5.Rotation

6.Eccentric rotation

7.Flywheel

8.Moving jaw

9.Adjustment setting

Application

Links:https://www.globefindpro.com/products/79075.html

-

XL Series Washing and Dewatering Screw

XL Series Washing and Dewatering Screw

-

Mobile Jaw Crusher

Mobile Jaw Crusher

-

ISP Series Impact Crusher

ISP Series Impact Crusher

-

Compound Crusher Parts

Compound Crusher Parts

-

PSG Series Cone Crusher

PSG Series Cone Crusher

-

PFQ Series Impact Crusher

PFQ Series Impact Crusher

-

PFX Series Impact Crusher

PFX Series Impact Crusher

-

Z Series Jaw Crusher

Z Series Jaw Crusher

-

TB Series Fibre Optic Borescope

TB Series Fibre Optic Borescope

-

GM-2000 Multi Angle Gloss Meter

GM-2000 Multi Angle Gloss Meter

-

HSA,HSD Digital Shore Durometer

HSA,HSD Digital Shore Durometer

-

CT-1000 Coating Thickness Gauge with Built-In Probe

CT-1000 Coating Thickness Gauge with Built-In Probe