PSG Series Cone Crusher

Overview

The PSG series cone crusher is a state-of-the-art high-performance crushing machine developed by YUANNAI according to inter-particle breakage principle. Adopting crushing concept instead of grinding, this machine is a perfect combination of high swing frequency, optimized chamber and rational stroke.

By far, this hydrocone crusher has been widely applied to metallurgy, building material, road building, chemical and silicate industries, suitable for breaking mid-had or above mid-hard ores and rocks.

Working Principle

When the cone crusher works, motor drives V-belt, big belt wheel, transmission shaft, bevel pinion and bevel gear pinion to make eccentric bushing rotate. Crushing cone axis is forced by the eccentric bushing to spin, which makes mantle sometimes close to the bowl liner, and some times far away from the bowl liner. Therefore, materials in the annular crushing chamber formed by fixed and mobile cones are continuously impacted, squeezed, curved and crushed. After repeat procedures, materials are crushed into required size and discharged from the outlet of quartz cone crusher.

Features

1. Excellent stability

Spring release mechanism will automatically release uncrushable materials and then is automatically reset to the fixed return point, during which crushable materials are normally discharged form the outlet of rock crusher.

2. High performance

Compared with spring cone crusher with same mobile cone, this equipment comes with higher performance and productivity.

3. Uniform particle size

Due to inter-particle breakage principle, final products come in cubic shape instead of flake shape, and particle size is more uniform.

4. Convenient chamber cleaning

When the machine stops under load conditions, hydraulic chamber cleaning system will rapidly clean crushing chamber, thus largely shortening downtime.

5. High reliability

This diabase cone crusher is outfitted with main shaft of large diameter, heavy-duty machine rack, standalone oil lubricating system and automatic control system, which greatly improves machine robustness, durability and reliability.

6. Easy operation and maintenance

All components of our cone crusher is demountable from the top or side of the machine, including fixed and mobile cone assembly. Bronze sliding bearing can still retain remarkable bearing capacity under environment of high impact and vibration. What's more, it is more economical and convenient for maintenance than rolling bearing.

7. Split type lubrication

Standalone oil lubricating system adopts split type lubrication to provide dual protection for bearing and realize automatic security protection.

8. Good sealing effect

Our basalt cone crusher makes use of compensating grease sealing to maximally prevent lubricating oil from dust pollution, which also effectively extends service life of components.

Technical Parameters

| Specification | Model | Chamber type | Outside diameter of crushing cone (mm) | Adjusting range of discharge gate (mm) | Feed size when minimum discharge gate is used (mm) | Max. feed size (mm) | Production capacity (t/h) | Motor power (KW) | Weight (t) | Overall Dimensions (mm) |

| 2'FT | PSGB-0607 | Standard fine crushing | 600 | 6-38 | 70 | 60 | 16-50 | 22 | 4500 | 2195×1158 ×1651 |

| PSGB-0609 | Standard moderate crushing | 10-38 | 95 | 80 | 18-65 | |||||

| PSGB-0611 | Standard coarse crushing | 13-38 | 110 | 90 | 22-70 | |||||

| PSGD-0603 | Short cone fine crushing | 3-13 | 35 | 30 | 9-35 | |||||

| PSGD-0605 | Short cone coarse crushing | 5-16 | 50 | 40 | 22-70 | |||||

| 3'FT | PSGB-0910 | Standard fine crushing | 900 | 9-22 | 102 | 85 | 45-91 | 75 | 9980 | 2656×1636 ×2241 |

| PSGB-0917 | Standard coarse crushing | 13-38 | 175 | 150 | 59-163 | |||||

| PSGB-0918 | Standard special coarse crushing | 25-38 | 178 | 150 | 118-163 | |||||

| PSGD-0904 | Short cone fine crushing | 3-13 | 41 | 35 | 27-90 | 10530 | ||||

| PSGD-0906 | Short cone moderate crushing | 3-16 | 76 | 65 | 27-100 | |||||

| PSGD-0907 | Short cone coarse crushing | 6-19 | 102 | 85 | 59-129 | |||||

| 4.25'FT | PSGB-1313 | Standard fine crushing | 1295 | 13-31 | 137 | 115 | 109-181 | 160 | 22460 | 2983×1866 ×3156 |

| PSGB-1321 | Standard moderate crushing | 16-38 | 210 | 178 | 132-253 | |||||

| PSGB-1324 | Standard coarse crushing | 19-51 | 241 | 205 | 172-349 | |||||

| PSGB-1325 | Standard special coarse crushing | 25-51 | 259 | 220 | 236-358 | |||||

| PSGD-1306 | Short cone fine crushing | 3-16 | 64 | 54 | 36-163 | 22590 | ||||

| PSGD-1308 | Short cone moderate crushing | 6-16 | 89 | 76 | 82-163 | |||||

| PSGD-1310 | Short cone coarse crushing | 8-25 | 105 | 89 | 109-227 | |||||

| PSGD-1313 | Short cone special coarse crushing | 16-25 | 133 | 113 | 209-236 | |||||

| 5.5'FT | PSGB-1620 | Standard fine crushing | 1676 | 16-38 | 209 | 178 | 181-327 | 220 | 43270 | 3941×2954 ×3771 |

| PSGB-1624 | Standard moderate crushing | 22-51 | 241 | 205 | 258-417 | |||||

| PSGB-1626 | Standard coarse crushing | 25-64 | 269 | 228 | 299-635 | |||||

| PSGB-1636 | Standard special coarse crushing | 38-64 | 368 | 313 | 431-630 | |||||

| PSGD-1607 | Short cone fine crushing | 5-13 | 70 | 60 | 90-209 | 43870 | ||||

| PSGD-1608 | Short cone moderate crushing | 6-19 | 89 | 76 | 136-281 | |||||

| PSGD-1613 | Short cone coarse crushing | 10-25 | 133 | 113 | 190-336 | |||||

| PSGD-1614 | Short cone special coarse crushing | 13-25 | 133 | 113 | 253-336 | |||||

| 7'FT | PSGB-2127 | Standard fine crushing | 2134 | 19-38 | 278 | 236 | 554-1034 | 400 | 86730 | 4613×3302 ×4638 |

| PSGB-2133 | Standard moderate crushing | 25-51 | 334 | 284 | 862-1424 | |||||

| PSGB-2136 | Standard coarse crushing | 31-64 | 369 | 314 | 1125-1814 | |||||

| PSGB-2146 | Standard special coarse crushing | 38-64 | 460 | 391 | 1252-1941 | |||||

| PSGD-2110 | Short cone fine crushing | 5-16 | 105 | 89 | 218-463 | 89500 | ||||

| PSGD-2113 | Short cone moderate crushing | 10-19 | 133 | 113 | 404-580 | |||||

| PSGD-2117 | Short cone coarse crushing | 13-25 | 178 | 151 | 517-680 | |||||

| PSGD-2120 | Short cone special coarse crushing | 16-25 | 203 | 172 | 580-744 |

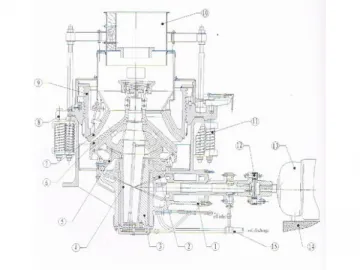

Structure Chart:

1.Frame

2.Pulley

3.Shaft

4.Pionion

5.Gear

6.Main shaft

7.Spring

8.Head

9.Mantle

10.Concave

11.Adjustment sleeve

12.Distributor plate

13.Feed inlet

14.Adjustment ring

15.Support

16.Support for bowl

17.Eccentric bushing

Application

Links:https://www.globefindpro.com/products/79080.html

-

PFQ Series Impact Crusher

PFQ Series Impact Crusher

-

PY Series Cone Crusher

PY Series Cone Crusher

-

Vertical Shaft Impactor Parts

Vertical Shaft Impactor Parts

-

GZD Series Vibrating Feeder

GZD Series Vibrating Feeder

-

Mobile Sand Making Plant

Mobile Sand Making Plant

-

Impact Crusher Parts

Impact Crusher Parts

-

Compound Crusher Parts

Compound Crusher Parts

-

ISP Series Impact Crusher

ISP Series Impact Crusher

-

Mobile Jaw Crusher

Mobile Jaw Crusher

-

XL Series Washing and Dewatering Screw

XL Series Washing and Dewatering Screw

-

YNKS Series Jaw Crusher

YNKS Series Jaw Crusher

-

PFX Series Impact Crusher

PFX Series Impact Crusher