PFQ Series Impact Crusher

Overview

The PFQ series impact crusher enjoys high praises among customers by virtue of high working efficiency. Applicable for coarse, moderate and fine crushing, it is well suited for materials with compressive strength of less than 250MPa, and has won consistent recognition among hydroelectric, expressway and artificial sand fields.

This vortex impact crusher is designed with unique construction, incorporated by vortex crushing chamber as well as P, S and T crushing sections. It also adopts rotor block of keyless connection, plug-in high-efficiency wear-resisting blow bar, inclined bearing block, unique toothed lining plate, multi-directional rack, lead screw, hydraulic device and other configurations.

Quick-wear part replacement and maintenance are extremely convenient and easy. For large-scale impact crusher, special tools for blow bar replacement and hoisting are optionally available.

Working Principle

This crushing equipment takes advantage of impact energy for material crushing. After entering blow bar action zone, materials are continuously cast forth to the impact device mounted above rotor under the action of high speed impact of blow bar. Then, materials are rebounded from impact lining plate to the blow bar action zone, and then are cast forth again. This procedure repeats till all materials are crushed into desired particles. Finally, the fine materials will be discharged out of the machine.

Features

1. This impact crusher for silica sand boasts original structure, easy operation mode, high working efficiency and less energy consumption. Basically, it has cubic profile, and is adjustable for discharged materials of different particle sizes.

2. Crushing procedures can be simplified to save production costs.

3. Heavy-duty bearing is used, featured by large bearing capacity.

4. Adopting heavy-duty design and strict test method, rotor comes with high quality.

5. Bearing block is made from one-piece cast steel, which ensures perfect match with machine rack and also greatly enhances radial strength.

6. The improved adjusting device largely shortens impact crusher downtime, and the roof opening device facilitates quick-wear part replacement.

7. Unique fixing device makes blow bar more reliable.

Technical Parameters

| Model | Max. Feeding size (mm) | Particle size of discharged materials (mm) | Production capacity(t/h) | Power (KW) | Overall dimension (mm) | Weight (kg) | |

| ≤150MPa | ≤250MPa | ||||||

| PFQ0808 | 200 | 150 | ≤25 (80-90%) | 46 | 55 | 1900×1860×2150 | 8800 |

| PFQ1108 | 300 | 180 | ≤30 (80-90%) | 80 | 90 | 2845×2148×2262 | 11079 |

| PFQ1110 | 400 | 200 | ≤35 (80-90%) | 112 | 110 | 2845×2360×2262 | 13510 |

| PFQ1310 | 500 | 250 | ≤40 (80-90%) | 180 | 160 | 3913×2511×2925 | 20095 |

| PFQ1313 | 600 | 250 | ≤40 (80-90%) | 225 | 220 | 3913×2719×2925 | 22650 |

| PFQ1315 | 700 | 300 | ≤50 (80-90%) | 280 | 280 | 3913×2969×2925 | 25500 |

| PFQ1320 | 700 | 300 | ≤50 (80-90%) | 350 | 2×200 | 3913×3402×2925 | 32386 |

| PFQ1515 | 1000 | 350 | ≤50 (80-90%) | 400 | 2×220 | 4310×3330×3660 | 39000 |

| PFQ1520 | 1000 | 400 | ≤50 (80-90%) | 500 | 2×280 | 4310×3330×3660 | 42000 |

| PFQ1720 | 1300 | 450 | ≤50 (80-90%) | 580 | 2×315 | 5540×3830×4600 | 57000 |

| PFQ1725 | 1300 | 500 | ≤50 (80-90%) | 670 | 2×355 | 5540×4330×4600 | 66000 |

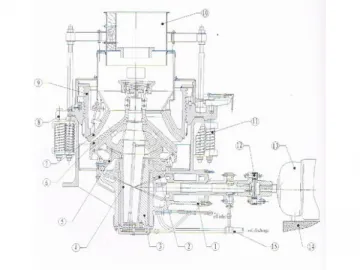

Structure Chart:

1.Bottom shell

2.Main shaft

3.Upper top rack

4.Rotor

5.Upper rear rack

6.Impact Plate

7.Screw rod

Links:https://www.globefindpro.com/products/79081.html

-

PY Series Cone Crusher

PY Series Cone Crusher

-

Vertical Shaft Impactor Parts

Vertical Shaft Impactor Parts

-

GZD Series Vibrating Feeder

GZD Series Vibrating Feeder

-

Mobile Sand Making Plant

Mobile Sand Making Plant

-

Impact Crusher Parts

Impact Crusher Parts

-

PFL Series Compound Crusher

PFL Series Compound Crusher

-

PSG Series Cone Crusher

PSG Series Cone Crusher

-

Compound Crusher Parts

Compound Crusher Parts

-

ISP Series Impact Crusher

ISP Series Impact Crusher

-

Mobile Jaw Crusher

Mobile Jaw Crusher

-

XL Series Washing and Dewatering Screw

XL Series Washing and Dewatering Screw

-

YNKS Series Jaw Crusher

YNKS Series Jaw Crusher