PY Series Cone Crusher

Overview

The PY series cone crusher enables to crush hard or medium hard ores and rocks, highlighted by high robustness and reliability, high productivity, easy adjustment, economical efficiency as well as many other merits.

At present, this cone crusher enjoys great popularity in metallurgy, construction, road building, chemical and phosphate industries, suited for crushing iron ore, copper ore, limestone, quartz, granite, basalt, diabase, etc. Standard, medium-sized or short cone head is optionally provided for coarse, moderate or fine crushing.

Performance Features

1. With mobile cone continuously rotating, material breaking and discharging are alternately accomplished. Thereby, both productivity and throughout capacity of this mobile cone crusher are improved.

2. Materials caught between two cones are constantly squeezed, curved and cut. Consequently, power consumption for material breaking is lower.

3. Final products are characterized by uniform size and cubic shape. After operation, the working surface of mobile cone comes with even wear.

4. Both mobile and fixed cones of this spring cone crusher are vertically installed. The two cones are parallel with certain interval during swinging of the mobile cone to ensure uniformity of final products.

5. Feed inlet size is not very large so that materials after primary crushing can enter the machine for further crushing.

6. Spring release system provides dependable overload protection so that the iron ore crusher won't be damaged by abnormally shaped materials.

7. Glycerin or water is adopted for sealing to isolate dusts and lubricating oil and to ensure reliable operation. This sealing method also helps to extend the service life of sliding bearing and thrust ball bearing.

8. Each cone crusher can be designed with different types of chamber to meet different application requirements.

Technical Parameters

| Model | Cone diameter(mm) | Adjusting range of discharge gate (mm) | Max. particle size of feedstock (mm) | Production capacity (t/h) | Motor power (KW) | Weight (t) | Overall Dimensions (mm) |

| PYB-600 | 600 | 12-25 | 65 | 15-25 | 30 | 5.5 | 1740×1225×1940 |

| PYD-600 | 3-13 | 36 | 5-23 | 30 | 5.5 | 1740×1225×1940 | |

| PYB-900 | 900 | 15-50 | 115 | 50-90 | 55 | 10.18 | 1990×1640×2380 |

| PYZ-900 | 5-20 | 60 | 20-65 | 55 | 10.19 | 1990×1640×2380 | |

| PYD-900 | 3-13 | 40 | 15-50 | 55 | 10.27 | 1990×1640×2380 | |

| PYB-1200 | 1200 | 20-50 | 145 | 110-200 | 110 | 24.7 | 2805×2300×2980 |

| PYZ-1200 | 8-26 | 100 | 50-150 | 110 | 25 | 2805×2300×2980 | |

| PYD-1200 | 3-15 | 50 | 18-105 | 110 | 25.6 | 2805×2300×2980 | |

| PYB-1750 | 1750 | 25-60 | 215 | 280-480 | 155-160 | 50.6 | 3610×2950×4185 |

| PYZ-1750 | 10-30 | 185 | 115-320 | 155-160 | 51 | 3610×2950×4185 | |

| PYD-1750 | 5-15 | 85 | 75-230 | 155-160 | 50.5 | 3610×2950×4185 | |

| PYB-2200 | 2200 | 30-60 | 300 | 590-1000 | 260-280 | 84 | 4790×3430×5080 |

| PYZ-2200 | 10-30 | 235 | 200-580 | 260-280 | 85 | 4790×3430×5080 | |

| PYD-2200 | 5-16 | 110 | 120-370 | 260-280 | 85 | 4790×3430×5080 |

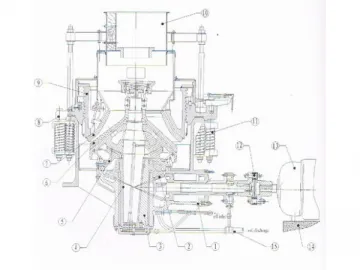

Structure Chart:

1.Frame

2.Transmission devices

3.Eccentric sleeve

4.Taper sleeve

5.Socket liner

6.Mantle

7.Concave

8.Adjusting device

9.Adjusting sleeve

10.Feeding hopper

11.Spring

12.Coupling

13.Motor

14.Foundation

15.Lubrication position

Application

Links:https://www.globefindpro.com/products/79082.html

-

Vertical Shaft Impactor Parts

Vertical Shaft Impactor Parts

-

GZD Series Vibrating Feeder

GZD Series Vibrating Feeder

-

Mobile Sand Making Plant

Mobile Sand Making Plant

-

Impact Crusher Parts

Impact Crusher Parts

-

PFL Series Compound Crusher

PFL Series Compound Crusher

-

Cone Crusher Parts

Cone Crusher Parts

-

PFQ Series Impact Crusher

PFQ Series Impact Crusher

-

PSG Series Cone Crusher

PSG Series Cone Crusher

-

Compound Crusher Parts

Compound Crusher Parts

-

ISP Series Impact Crusher

ISP Series Impact Crusher

-

Mobile Jaw Crusher

Mobile Jaw Crusher

-

XL Series Washing and Dewatering Screw

XL Series Washing and Dewatering Screw