NVIS Series Vertical Shaft Impactor

Overview

The NVIS series vertical shaft impactor is an up-to-date impact crusher with multiple independent patent property rights. As a prefect combination of professional crushing technologies and machinery manufacturing, it is also a high-efficiency sand maker playing a critical role in sand making industry.

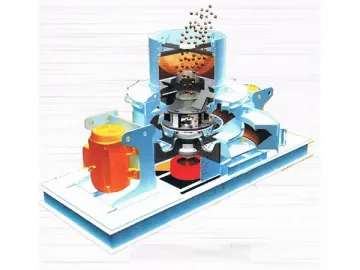

Working Principle

The vertical shaft impactor makes use of advanced selective crushing and cleavage breakage principles and directly imposes sufficient kinetic energy to materials. Meanwhile, it exerts impact force to transform kinetic energy into crushing energy for material crushing. Materials are broken along cleavage plane, and final products come with uniform particle size.

In addition, this iron ore crusher works with low energy consumption. Material-to-material and material-to-metal crushing modes are interconvertible.

Performance Features

1.Our machine runs on electric power and won’t overload or damage the motor.

2.The core material used to build the machine is wear-resistant and temperature-resistant.

3.Using a two-hammer design means you only have to replace one worn out part at a time, but the machine can still function, reducing the operation cost by 30%. A vice hammer will prevent damage to the vertical plate if the main hammer wears out.

4.A crushing chamber reduces the resistance of materials flowing through the chamber and has a high holding capacity.

5.Bearings are imported from well-known international brands in Japan, Sweden, and the U.S.

Technical Parameters

| Model | Max. feed size (mm) | Impeller speed(r/min.) | Motor power (KW) | Feed mode | Overall Dimensions (mm) | Output (t/h) |

| NVIS7000 | ≤35 | 1775-1965 | 75-132 | Center feeding | 3295×Φ1840×2771 | 70-215 |

| NVIS8000 | ≤45 | 1460-1620 | 160-220 | Center feeding | 3588×Φ2200×2790 | 150-410 |

| NVIS9000 | ≤50 | 1242-1375 | 200-315 | Center feeding | 3745×Φ2430×3500 | 225-470 |

| NVIS9000 | ≤50 | 1242-1375 | 2×(132-250) | Center feeding | 5160×Φ2430×3500 | 240-525 |

| NVIS9500 | ≤55 | 950-1242 | 2×(200-315) | Center feeding | 5570×Φ2660×3550 | 380-680 |

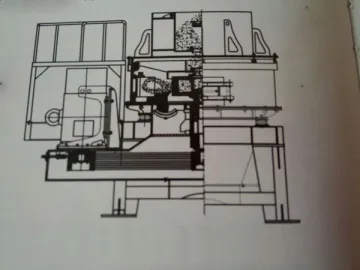

Structure Chart:

Single Motor Construction Blueprint

Application

Links:https://www.globefindpro.com/products/79095.html

-

Belt Conveyor

Belt Conveyor

-

Mobile Compound Crusher

Mobile Compound Crusher

-

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor

-

Mobile Cone Crusher

Mobile Cone Crusher

-

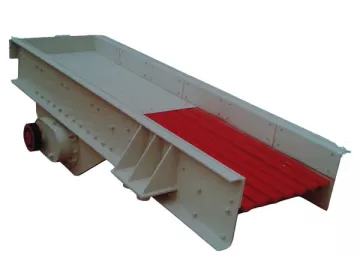

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

Seamless Steel Structural Pipe, Delivery Pipe

Seamless Steel Structural Pipe, Delivery Pipe

-

PL Series Vertical Shaft Impactor

PL Series Vertical Shaft Impactor

-

Jaw Crusher Parts

Jaw Crusher Parts

-

Hot Rolled Seamless Steel Pipe

Hot Rolled Seamless Steel Pipe

-

Seamless Steel Pipe for Boiler

Seamless Steel Pipe for Boiler

-

Mobile Impact Crusher

Mobile Impact Crusher