Belt Conveyor

Overview

The belt conveyor is a kind of widely used conveying equipment in chemical, coal, metallurgy, mining, casting, power, food, building materials, light industry, transportation, production line, hydropower station, construction site, port and other fields. To meet requirements of differently arranged operation lines, our belt conveyor enables single or union operation. Or it can be coupled with other machines for horizontal or slant conveying operation.

Service Conditions

1. This band conveyor is serviceable at ambient temperature of -20°C to 40°C.

2. Material temperature should be below 50°C.

3. Materials should be packaged or bulk granular or powdery materials with bulk density of 0.5-2.5t/m³.

4. Acid, alkaline materials and oils cannot be conveyed by this belt conveyor.

Installation Modes

This grain conveyor can be installed in horizontal, slant, fixed or mobile mode.

Performance Features

Based on friction drive principle, this equipment comes with merits like large conveying capacity, long conveying distance, high stability, small noise, simple structure, easy maintenance, low energy consumption, component standardization and no relative motion between materials and the machine itself.

Working Principle

Our belt conveyor mainly incorporates rack, conveying belt, belt roller, tension device and transmission gear. Main body is fabricated by superior steel plates, and rack surface is at certain slant angle due to height difference of front and rear supporting legs.

The rack is configured with belt roller, carrier roller and other parts for driving and supporting the conveying belt. Basically, gear motor and electric roller are available for machine driving. Besides, platform can be equipped for maintenance convenience on customer's request.

Technical Parameters

| Model | Production capacity (m3/h) | Max. particle size of conveying materials (mm) | Speed (m/s) | Power (KW) | Weight (kg) | |

| 10m | ±1m | |||||

| B500 | 25-143 | 1830 | 73 | |||

| B650 | 40-243 | 200 | 0.8-2.5 | >1.5 | 2200 | 116 |

| B800 | 70-500 | 300 | 0.8-2.5 | >2.2 | 3600 | 153 |

| B1000 | 140-170 | 380 | 0.8-3.15 | >3.0 | ||

| B1200 | 210-1370 | 400 | 0.8-4.0 | >4.0 | ||

| B1400 | 290-1800 | 500 | 0.8-4.0 | >4.0 | ||

Links:https://www.globefindpro.com/products/79096.html

-

Mobile Compound Crusher

Mobile Compound Crusher

-

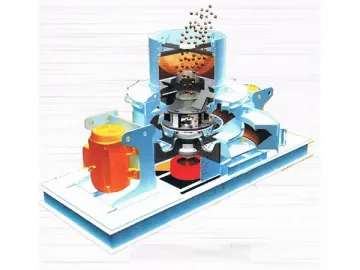

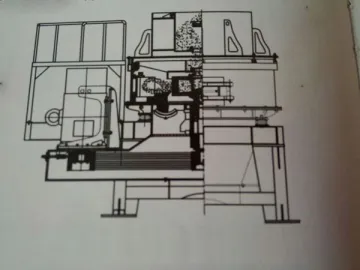

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor

-

Mobile Cone Crusher

Mobile Cone Crusher

-

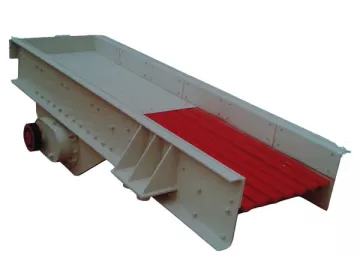

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

YK Series Circular Motion Vibrating Screen

YK Series Circular Motion Vibrating Screen

-

NVIS Series Vertical Shaft Impactor

NVIS Series Vertical Shaft Impactor

-

Seamless Steel Structural Pipe, Delivery Pipe

Seamless Steel Structural Pipe, Delivery Pipe

-

PL Series Vertical Shaft Impactor

PL Series Vertical Shaft Impactor

-

Jaw Crusher Parts

Jaw Crusher Parts

-

Hot Rolled Seamless Steel Pipe

Hot Rolled Seamless Steel Pipe

-

Seamless Steel Pipe for Boiler

Seamless Steel Pipe for Boiler