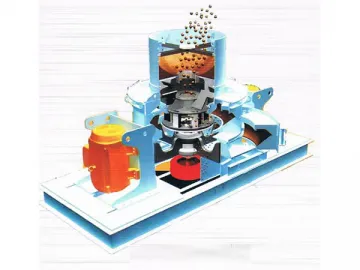

PCL Series Vertical Shaft Impactor

Overview

The PCL series vertical shaft impactor boasts fall-like feed system incorporated by distributor, control panel, control gate and overflow baffle. With material quantity control, this feed system brings material flow into crushing chamber, timely supplementing material volume and density inside the crushing chamber and also promoting energy transfer among materials. Compared with similar domestic products, our carborundum impact crusher with low investment cost and high returns is more competitive.

Application

The vertical shaft impactor has been widely used in building, cement, chemical engineering, glass, water conservancy, porcelain, metallurgy, industrial ore and metal ore fields. It possesses incomparable superiorities for moderate, fine and coarse crushing.

Specifically, this crushing machine is well suited for mid-hard, hard and brittle materials, such as corundum, carborundum, quartz, calley-stone, ceramic raw material, fireproofing, concrete aggregate, magnesite clinker, carbon, bauxite, slag, granite, basalt, etc.

Performance Features

1. Our vertical shaft impactor can precisely control product particle size, and final products come in uniform cubic shape.

2. Motor maximally utilizes available electric power, and overload won't occur.

3. As the sand making machine adopts rational structure design, quick-wear parts can be used for a long time. Meanwhile, operation cost is low and maintenance time is shortened.

4. By adjusting size, angle and position of overflow baffle, optimal material flow is ensured. In the meantime, wear-resistant parts of rotor and crushing chamber are well protected.

5. Through utilizing different circular chamber liners, this vertical shaft impactor enables to perform moderate and fine crushing as well as sand making.

6. Control panel and control gate can be adjusted to reduce material inlet size and minimize the occurrence of airflow cutoff. Therefore, ideal airflow circulation inside the crushing chamber is realized, and dust collection is easier.

7. Large production capacity of 50-870t/h is achieved, which is increased by 30%-50% compared with that of traditional machines.

8. This vertical shaft impactor for ceramic raw material is not restrained by moisture content of materials. After processing, moisture content of materials can be reduced to 8%.

9. Metal contamination won't be caused.

Technical Parameters

| Model | Impeller Speed (r/min) | Power (kw) | Feeding method | Max. Feeding size(mm) | Capacity(t/h) | Overall Dimension(mm) |

| PCL-550 | 2258~2500 | 30~55 | Cascade and center feeding | ≤30 | 32-150 | 2555*φ1660*2452 |

| Center feeding | ≤30 | 25-80 | ||||

| PCL-700 | 1775~1965 | 55~90 | Cascade and center feeding | ≤35 | 90-260 | 3295*φ1840*2771 |

| Center feeding | ≤35 | 60-125 | ||||

| PCL-850(D) | 1460~1620 | 90-160 | Cascade and center feeding | ≤45 | 160-340 | 3588*φ2200*2790 |

| Center feeding | ≤40 | 115-260 | ||||

| PCL-850 | 1460~1620 | 2*(55-110) | Cascade and center feeding | ≤50 | 215-390 | 4800*φ2200*2895 |

| Center feeding | ≤40 | 130-300 | ||||

| PCL-1000 | 1242~1375 | 2*(110-200) | Cascade and center feeding | ≤60 | 320-580 | 5160*φ2430*3500 |

| Center feeding | ≤55 | 225-380 | ||||

| PCL-1200 | 950-1242 | 2*(200-315) | Cascade and center feeding | ≤60 | 410-720 | 5570*φ2660*3550 |

| Center feeding | ≤55 | 350-580 |

Notes

1. Production capacity in the table is achieved under three conditions as follows:

a. Compressive strength of limestone is ≤150MPa.

b. Bulk density is 1.6t/m3.

c. Feed is continuous and sufficient.

2. Different installed power can be adopted based on standard production capacity.

3. Product output is closely related to factors like material variety, power, impeller speed, crushing chamber construction, feedstock granular composition, craft, etc.

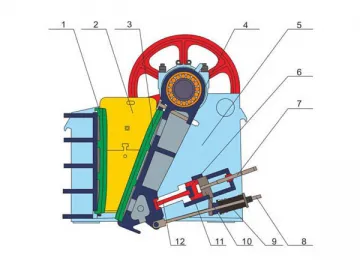

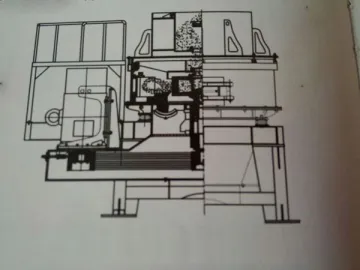

Internal Structure Chart:

PCL Crusher Inner Structure PCL Crushing Chamber

Application

Links:https://www.globefindpro.com/products/79098.html

-

Mobile Cone Crusher

Mobile Cone Crusher

-

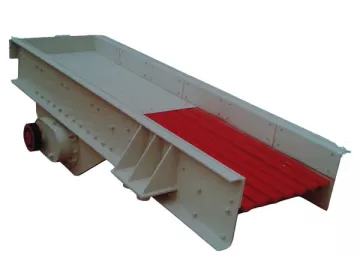

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

YK Series Circular Motion Vibrating Screen

YK Series Circular Motion Vibrating Screen

-

DXS Series Dewatering Bucket Wheel

DXS Series Dewatering Bucket Wheel

-

PE Series Jaw Crusher

PE Series Jaw Crusher

-

Mobile Compound Crusher

Mobile Compound Crusher

-

Belt Conveyor

Belt Conveyor

-

NVIS Series Vertical Shaft Impactor

NVIS Series Vertical Shaft Impactor

-

Seamless Steel Structural Pipe, Delivery Pipe

Seamless Steel Structural Pipe, Delivery Pipe

-

PL Series Vertical Shaft Impactor

PL Series Vertical Shaft Impactor

-

Jaw Crusher Parts

Jaw Crusher Parts