Mobile Cone Crusher

Overview

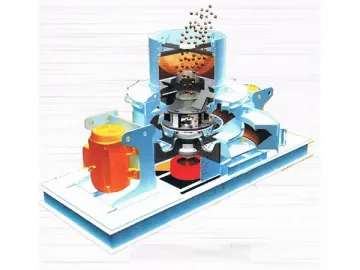

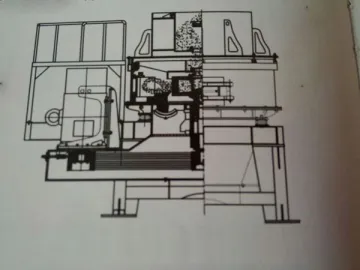

The mobile cone crusher is mainly comprised of high-performance vibrating screen, high-efficiency belt conveyor, control cabinet, motor and other configurations. With one-piece construction, it boasts of outstanding maneuverability and flexibility, and can be coupled with other machines for collaborative operation. Meanwhile, this cone crusher together with configurations like vibrating screen and motor can be tailored to meet different operation requirements.

Generally, our mobile cone crusher is applied to fine crushing of hard materials like sandstone. It also can be designed with different types of crushing chamber, thus application range is much wider.

Working Principle

Materials are uniformly conveyed to the crushing machine via feeder. After preliminary crushing, a closed-loop system is formed by circular vibrating screen, and thereby circular material breaking is realized. Finally, end products will be discharged by conveyor. Our mobile cone crusher can also work without using the circular vibrating screen for direct material breaking.

Features

1. Instead of split-type construction, this mobile crusher dispenses with cumbersome facility assembly, thus reducing material and time expenditure. Besides, compact design maximally optimizes field utilization.

2. Characterized by high adaptability and flexibility, this equipment enables both self-managed and collaborative operations. Besides, side-operative hopper makes for diversified material conveying modes.

3. Diesel generator provides power for this sandstone crusher and other collaborative devices.

4. By virtue of excellent operation performance, robust design, rational construction and high crushing efficiency, our mobile cone crusher provides reliable and stable product quality assurance, ideal for coarse, moderate and fine crushing. Besides, it is maintenance friendly.

Technical Parameters

| Items | Model | |||||

| YNCC-320 | YNCC-210 | YNCC-630 | YNCC-635 | YNCC-336 | YNCC-420 | |

| Dimension | ||||||

| Length (mm) | 14700 | 13200 | 15500 | 15250 | 15690 | 15690 |

| Width (mm) | 3040 | 2780 | 2865 | 3000 | 3290 | 3300 |

| Height (mm) | 4220 | 4180 | 4300 | 4500 | 4500 | 4510 |

| Weight (t) | 45.1 | 36.1 | 55.6 | 55.8 | 53 | 54.4 |

| Axle load (t) | 30.8 | 25.8 | 25.6 | 35.5 | 34.5 | 35.8 |

| Traction pin load (t) | 90/14.3 | 50/10.3 | 90/20 | 90/20.3 | 90/18.5 | 90/18.6 |

| Cone crusher | ||||||

| Model | PSGD-1620 | PSGD-1607 | PSGD-1636 | PSGD-1626 | PSGD-1613 | PSGD-1624 |

| Max. inlet size (mm) | 178 | 60 | 313 | 228 | 113 | 205 |

| Adjusting range of material outlet (mm) | 16-38 | 5-13 | 38-64 | 28-64 | 10-25 | 22-51 |

| Production capacity (t/h) | 181-327 | 90-209 | 431-630 | 299-635 | 190-336 | 258-417 |

| Vibrating screen | ||||||

| Model | 3YK2160 | 3YK1836 | 3YK2160 | 3YK2160 | 3YK2160 | 3YK2160 |

| Belt conveyor | ||||||

| Model | B1000×6.5Y | B1000×7.2Y | B1000×8.2Y | B1000×8.2Y | B1000×8.2Y | B1000×8.2Y |

| Shaft quantity | ||||||

| Quantity | Three shafts | Three shafts | Three shafts | Three shafts | Three shafts | Three shafts |

Links:https://www.globefindpro.com/products/79099.html

-

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

YK Series Circular Motion Vibrating Screen

YK Series Circular Motion Vibrating Screen

-

DXS Series Dewatering Bucket Wheel

DXS Series Dewatering Bucket Wheel

-

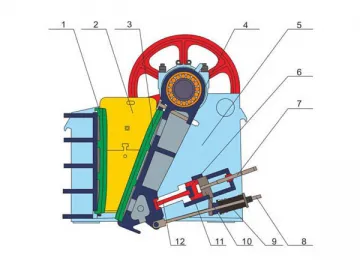

PE Series Jaw Crusher

PE Series Jaw Crusher

-

Double Head CNC Engraving Machine

Double Head CNC Engraving Machine

-

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor

-

Mobile Compound Crusher

Mobile Compound Crusher

-

Belt Conveyor

Belt Conveyor

-

NVIS Series Vertical Shaft Impactor

NVIS Series Vertical Shaft Impactor

-

Seamless Steel Structural Pipe, Delivery Pipe

Seamless Steel Structural Pipe, Delivery Pipe

-

PL Series Vertical Shaft Impactor

PL Series Vertical Shaft Impactor