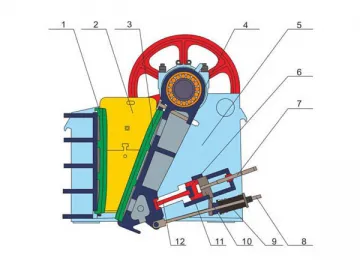

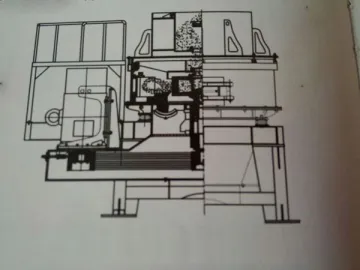

PFB Series Impact Crusher

Overview

This series of product is used for medium-sized crushing projects for medium to hard materials in the road, water and electricity, and building industries.

Working Principle

Basically, the gypsum impact crusher takes full advantage of impact energy for working. Blow bar is configured above the rotor rotating at a high speed and driven by motor. Once entering the action zone of blow bar, materials will be stricken by the blow bar and then thrown to impact device continuously. After that, materials will be rebounded from the impact plate to the action zone of blow bar for repeat crushing. By means of continuous processing, materials will be crushed to desired size and discharged from machine outlet. The interval between impact rack and the rotor can be regulated for obtaining final products of different sizes and shapes.

Features

1. This machine is equipped with a fully hydraulic opening so operators can maintain or replace worn out parts.

2. The feeder can accept pieces within the range of 100mm to 500mm.

3. The size of the finished product can be adjusted by regulating the interval between the blow bar and impact plate.

Parameters

| Model | Particle size of feedstock (mm) | Particle size of discharged materials (mm) | Production capacity (t/h) | Power (KW) | Overall dimension (mm) | Weight (kg) |

| PFB1108 | <300 | <50 | 35-60 | 45-75 | 2500×2210×2700 | 10400 |

| PFB1110 | <300 | <50 | 60-90 | 75-110 | 2500×2460×2700 | 12300 |

| PFB1310 | <350 | <50 | 80-110 | 90-132 | 2900×2408×3000 | 16960 |

| PFB1313 | <350 | <50 | 90-140 | 132-160 | 2900×2658×3000 | 22300 |

| PFB1314 | <350 | <50 | 100-160 | 132-180 | 2900×3190×3100 | 23600 |

| PFB1315 | <400 | <50 | 160-250 | 180-260 | 3100×3290×3100 | 25600 |

| PFB1320 | <500 | <50 | 280-350 | 300-375 | 3200×3790×3100 | 29800 |

Application

Links:https://www.globefindpro.com/products/79101.html

-

YK Series Circular Motion Vibrating Screen

YK Series Circular Motion Vibrating Screen

-

DXS Series Dewatering Bucket Wheel

DXS Series Dewatering Bucket Wheel

-

PE Series Jaw Crusher

PE Series Jaw Crusher

-

Double Head CNC Engraving Machine

Double Head CNC Engraving Machine

-

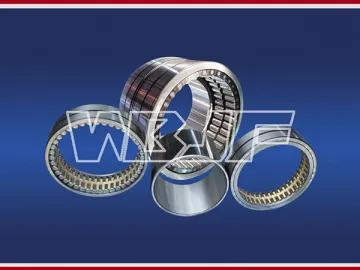

Four-Row Cylindrical Roller Bearings

Four-Row Cylindrical Roller Bearings

-

Hot Expanded Seamless Steel Pipe

Hot Expanded Seamless Steel Pipe

-

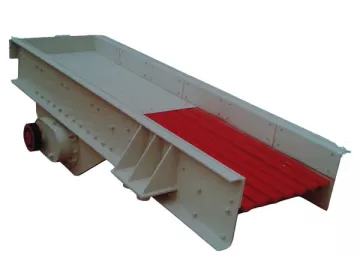

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

Mobile Cone Crusher

Mobile Cone Crusher

-

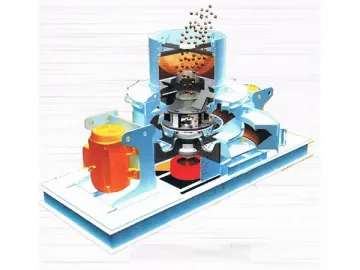

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor

-

Mobile Compound Crusher

Mobile Compound Crusher

-

Belt Conveyor

Belt Conveyor

-

NVIS Series Vertical Shaft Impactor

NVIS Series Vertical Shaft Impactor