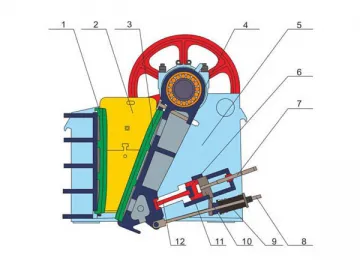

YK Series Circular Motion Vibrating Screen

This YK series circular motion vibrating screen is a new efficient multilayer screening machine vibrating in a circular motion. It is configured with cylinder vibrator with eccentric shaft, as well as eccentric block for adjusting amplitude. Materials can be sorted in different specifications in a long screening line. Designed in reliable structure, this circular motion vibrating screen features great exciting force, high screening efficiency, low vibrating noise, excellent durability, ease of maintenance and operation, etc.

This screening equipment is specially engineered to sift stones in the quarry, and widely applied in grading the products of mining, building materials, transportation, energy, chemical industry and other fields. It is the ideal member of the crushing and screening machine groups. If it needs to screen the wet and sticky materials, users have to spray water on the screen cloth with small sized aperture.

Working Principle

Driven by general motor, the eccentric shaft leads the vibrating screener to vibrate periodically in the direction of exciting force. On the screen deck, the materials move in circle to reach required screening effect. Composed of vibrator, screen body, screen cloth, damping device and pedestal, this circular motion vibrating screen is well constructed and durable.

Features

1.This circular motion vibrating screen utilizes the eccentric block that generates powerful exciting force.

2. High strength bolt is adopted to connect the beams to the screening box instead of welding.

3. Our device is equipped with spring steel braided net or perforated screen plate so that it is not easy to be blocked and has a long operating life.

4. Rubber spring can reduce vibration, resulting in low noise, long service life, and stable resonance region.

Technical Parameters

| Model | Layer | Screen aperture size (mm) | Double vibrationamplitude(mm) | Vibrating frequency (r/min.) | Max. particle size of feedstock(mm) | Production capacity (t/h) | Power (KW) | Weight (kg) |

| YK1437 | 1/2 | 3-50 | 6-8 | 970 | 200 | 240 | 11/15 | 3087/4400 |

| YK1445 | 1/2 | 3-50 | 6-8 | 970 | 200 | 272 | 11/15 | 3523/4750 |

| YK1545 | 1/2 /3/4 | 3-50 | 6-8 | 970 | 200 | 285 | 11/15 /22/30 | 3292/4893/6375/8332 |

| YK1645 | 1/2 | 3-50 | 6-8 | 970 | 200 | 310 | 15/18.5 | 3590/5750 |

| YK1836 | 2/3 | 13-100 | 6-8 | 970 | 200 | 81-742 | 22 | 5480/7085 |

| YK1845 | 2/3 | 13-100 | 8 | 970 | 200 | 97-891 | 30 | 5736/7850 |

| YK1854 | 2/3 | 13-100 | 8 | 850 | 200 | 113-680 | 30 | 7985/9750 |

| YK1860 | 1/2/3 | 13-100 | 8 | 860 | 200 | 115-756 | 22/30 /37 | 6878/8300/10350 |

| YK2052 | 2/3/4 | 13-100 | 6-9 | 850 | 200 | 126-728 | 30/37/45 | 8250/9995/12500 |

| YK2060 | 2/3 | 13-100 | 6-9 | 850 | 200 | 144-840 | 22/30 | 7500/10570 |

| YK2145 | 2/3 | 13-100 | 8 | 850 | 200 | 111-660 | 22/30 | 6950/9900 |

| YK2160 | 2/3 | 13-100 | 6-9 | 850 | 200 | 150-882 | 37/45 | 8700/10750 |

| YK2452 | 2/2 | 13-100 | 6-9 | 850 | 200 | 151-873 | 37/45 | 11050/11758 |

| YK2460 | 2/3 | 13-100 | 6-9 | 850 | 200 | 172-1000 | 37/45 | 8850/11050 |

| YK3052 | 1/2 | 13-100 | 6-9 | 850 | 200 | 189-1092 | 30/45 | 9225/10079 |

| YK3060 | 1/2 | 13-100 | 6-9 | 850 | 200 | 216-1260 | 30/55 | 9800/11000 |

Application

Links:https://www.globefindpro.com/products/79102.html

-

DXS Series Dewatering Bucket Wheel

DXS Series Dewatering Bucket Wheel

-

PE Series Jaw Crusher

PE Series Jaw Crusher

-

Double Head CNC Engraving Machine

Double Head CNC Engraving Machine

-

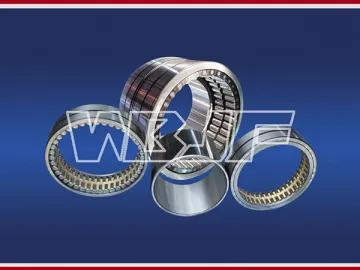

Four-Row Cylindrical Roller Bearings

Four-Row Cylindrical Roller Bearings

-

Hot Expanded Seamless Steel Pipe

Hot Expanded Seamless Steel Pipe

-

CC Series Spherical Roller Bearings

CC Series Spherical Roller Bearings

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

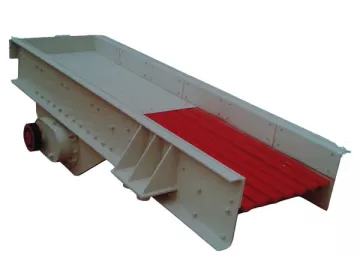

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

Mobile Cone Crusher

Mobile Cone Crusher

-

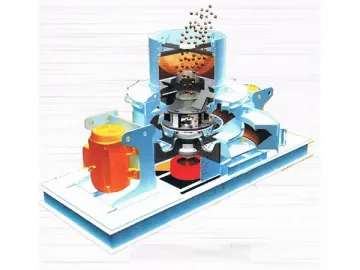

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor

-

Mobile Compound Crusher

Mobile Compound Crusher

-

Belt Conveyor

Belt Conveyor