PE Series Jaw Crusher

Overview

The PE series jaw crusher is primarily used to crush ores and blocky materials of medium particle size (125-1120mm). Generally, it enables coarse crushing and fine crushing, and the compressive strength of materials shouldn’t be more than 320MPa.

This series of jaw crusher is provided in a wide range, ideal for primary crushing. At present, it has been extensively applied to mining, metallurgy, construction, highway, railway, water conservancy, chemical engineering, ceramics, fireproofing and other industries.

Features

1. Discharge gate comes with wide adjustable range (see details in the parameter table as below) to meet different requirements of customers. The gasket type adjusting device is user friendly and also enhances operational flexibility and stability.

2. This crushing equipment saves energy by 15%-30%, and energy saving rate of entire system is nearly doubled.

3. The lubricating system of our jaw crusher is reliable, safe and easy for part replacement, making for small maintenance load, less downtime and high service efficiency.

Working Principle

The mining crusher makes use of drive and extrusion principle for crushing. With belt and belt pulley driven by motor, movable jaw is in vertical motion via eccentric shaft. The included angle between toggle plate and movable jaw increases with the rise of movable jaw, thus pushing the movable jaw plate to approach to fixed jaw plate. At this time, materials are ejected into crushing chamber under the large force of jaw tooth, and are then broken into materials of smaller sizes.

When the movable jaw of jaw crusher for metallurgy descends, the included angle between toggle plate and movable jaw decreases, and the movable jaw plate departs from the fixed jaw plate under the action of pull rod and spring. By this time, crushed materials have been expelled out of crushing chamber.

With continuous rotation of motor, periodic material crushing and discharging are performed for batch production. You will be surprised by the performance of our jaw crusher.

Parameters

| Model and specification | Max. particle size of feedstock(mm) | Discharging gate size(mm) | Production capacity(m3/h) | Rotating speed of eccentric shaft (r/min.) | Power (KW) | Overall dimension(mm) | Weight(kg) |

| PEF250×400 | 210 | 20-60 | 3-13 | 300 | 15 | 1108×1142×1392 | 3000 |

| PEF400×600 | 340 | 40-100 | 10-40 | 275 | 30 | 1700×1732×1653 | 6800 |

| PEF500×750 | 425 | 50-100 | 34-68 | 275 | 55 | 2050×1860×2154 | 11320 |

| PEF600×900 | 480 | 75-200 | 32-120 | 255 | 75 | 2792×2168×2250 | 17600 |

| PEF750×1060 | 630 | 75-200 | 75-150 | 255 | 110 | 2920×2424×2950 | 26000 |

| PEF750×1200 | 650 | 80-160 | 96-200 | 210 | 110 | 4445×3014×3415 | 42632 |

| PEF900×1060 | 700 | 230-350 | 218-300 | 250 | 110 | 3160×2424×2950 | 32600 |

| PEF900×1200 | 750 | 95-200 | 140-280 | 200 | 132 | 3500×2826×3270 | 50000 |

| PEF1000×1200 | 850 | 195-265 | 200-350 | 200 | 185 | 3600×2826×3280 | 52600 |

| PEF1200×1500 | 1020 | 150-300 | 270-500 | 180 | 200 | 4300×3540×4043 | 88000 |

| PEF1300X1500 | 1120 | 250-400 | 400-700 | 180 | 250 | 4500×3540×4043 | 96000 |

| PEX150×500 | 125 | 10-40 | 5-12 | 300 | 11 | 1200×1230×1180 | 2470 |

| PEX150×750 | 125 | 10-40 | 5-15 | 300 | 15 | 1220×1480×1180 | 3600 |

| PEX250×750 | 210 | 10-50 | 8-22 | 300 | 22 | 1400×1617×1412 | 4980 |

| PEX200×1000 | 160 | 10-50 | 9-25 | 300 | 22 | 1480×1992×1380 | 6800 |

| PEX250×1000 | 210 | 15-55 | 10-32 | 300 | 30 | 1580×1992×1380 | 7350 |

| PEX250×1200 | 210 | 15-60 | 12-38 | 300 | 37 | 1530×2192×1380 | 8700 |

| PEX300×1300 | 250 | 20-90 | 15-65 | 300 | 75 | 1930×2400×1747 | 11600 |

| PEX400×750 | 320 | 15-50 | 12-40 | 300 | 37 | 1800×1742×1863 | 9510 |

| PEX400×1200 | 340 | 20-80 | 18-60 | 330 | 55 | 1650×2192×1863 | 11278 |

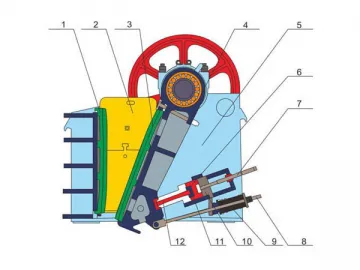

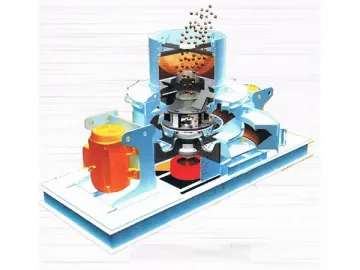

Structure Chart:

1.Fixed jaw plate

2.Liner board

3.Movable jaw plate

4.Movable jaw

5.Cram

6.Toggle plate base

7.Push rod

8.Draw rod

9.Spring

10.Adjusting gasket

11.Toggle plate cushion

12.Toggle plate

Links:https://www.globefindpro.com/products/79104.html

-

Double Head CNC Engraving Machine

Double Head CNC Engraving Machine

-

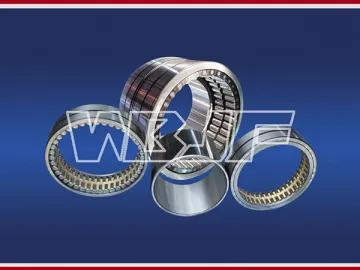

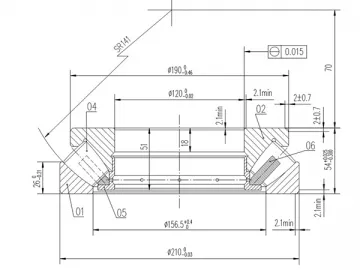

Four-Row Cylindrical Roller Bearings

Four-Row Cylindrical Roller Bearings

-

Hot Expanded Seamless Steel Pipe

Hot Expanded Seamless Steel Pipe

-

CC Series Spherical Roller Bearings

CC Series Spherical Roller Bearings

-

FurniMat CNC Woodworking Machine

FurniMat CNC Woodworking Machine

-

Spherical Roller Thrust Bearings

Spherical Roller Thrust Bearings

-

DXS Series Dewatering Bucket Wheel

DXS Series Dewatering Bucket Wheel

-

YK Series Circular Motion Vibrating Screen

YK Series Circular Motion Vibrating Screen

-

PFB Series Impact Crusher

PFB Series Impact Crusher

-

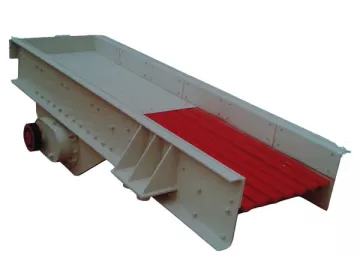

ZSW Series Vibrating Feeder

ZSW Series Vibrating Feeder

-

Mobile Cone Crusher

Mobile Cone Crusher

-

PCL Series Vertical Shaft Impactor

PCL Series Vertical Shaft Impactor