CNC Tapping Machine

The DT series CNC tapping machine is a newly-developed, highly efficient and precise CNC lathe, and it is capable of drilling, tapping and chamfering jobs. It is commonly used in manufacturing industry, aerospace industry, medical apparatus and electronic device production process. More specifically, our CNC tapping center is extremely suitable to make threaded holes on cooling fins, air valves, oil valves, bearing pedestals, connecting plates, household hardware, LED aluminum profiles, sheet metal parts, die cast parts, injection molded parts, servo motor rear encoder covers, etc.

Features

1. As the name implies, tapping is the most important function of a CNC tapping machine. According to specific processing requirements, users could set tapping turns, retraction turns as well as depth compensation, and users could also regulate tapping speed including feed speed and return speed, thus maximizing cutter’s service life, final machining result and tapping efficiency.

2. The drilling process contains two choices, one is driven by high-speed main spindle and the other is driven by low-speed main spindle. The high-speed spindle fits for bottom hole drilling (M3 and below), and it improves drilling efficiency for small holes. On the other hand, the low-speed spindle offer enough torque when dealing with large holes.

3. The chamfering function works instead of low-efficient manual machining, perfectly promoting overall working efficiency.

4. Our CNC tapping machine also has vibratory feeding function, and the vibration frequency is adjustable. Under this working mode, the tap vibrates when moving in the hole, and this offers effective solutions when threading small or hard-to-machine holes, such as ones made of stainless steel or titanium alloy.

5. The CNC threading machine has a high-speed digital signal controller and a large true color LCD screen. The clear operation interface makes it very convenient to manipulate this CNC machine, and the online programming function allows self-learning. In addition, offline programming is also realized, and the programmed data are loaded by U disk or Ethernet.

6. The control system has one key recovery function, and the control software could be upgraded through the Internet.

7. Our CNC tapping machine contains different configurations to meet various processing requirements of actual applications, and the available function combination includes drilling-tapping, drilling-tapping-chamfering, multi main spindles for drilling-tapping-chamfering different-sized holes, etc.

Technical Data

| Model | DT-1315 | Unit |

| Positioning accuracy | ±0.02 | mm |

| Variable frequency main spindle motor | Drilling: 1.5 | kW |

| Tapping: 0.4 | ||

| Max. main spindle speed | 24000 | rpm |

| Max. spindle speed when drilling | 200 | |

| Drill bit diameter | 1.25-6.8 | mm |

| Tapping diameter | M1.6-8 | |

| Rapid moving speed | 18 | m/min |

| Overall dimensions | 2200×800×1440 | mm |

| Max. stroke | 1000×250×110 | mm |

| Working area | 850×240×110 | mm |

| Power supply | AC 220±10%/50 | V/Hz |

| Applicable material | Iron, copper, aluminum and organic material | - |

| Power consumption | 3 | kW |

| Weight | 1500 | kg |

Note: The technical data of CNC tapping machine are subject to change without prior notice, and they are in accordance with our technical standard.

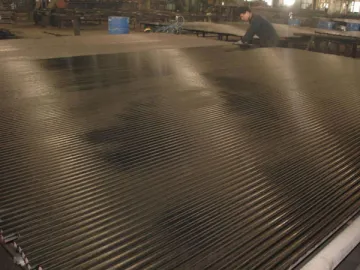

Processing Samples

Links:https://www.globefindpro.com/products/79118.html

-

CNC Engraving Machine with Polished Effect

CNC Engraving Machine with Polished Effect

-

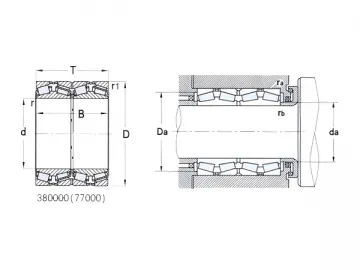

Four-Row Tapered Roller Bearings

Four-Row Tapered Roller Bearings

-

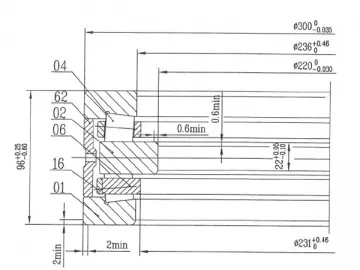

Double-Row Angular Contact Ball Bearings

Double-Row Angular Contact Ball Bearings

-

Tapered Roller Thrust Bearings

Tapered Roller Thrust Bearings

-

Galvanized Steel Pipe

Galvanized Steel Pipe

-

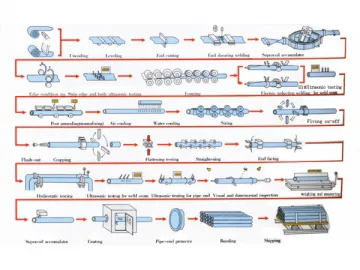

LSAW Steel Pipe

LSAW Steel Pipe

-

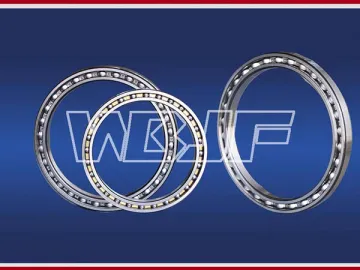

Four-Point Angular Contact Ball Bearings

Four-Point Angular Contact Ball Bearings

-

ERW Steel Pipe

ERW Steel Pipe

-

Deep Groove Ball Bearings

Deep Groove Ball Bearings

-

Foam Cutting Machine

Foam Cutting Machine

-

Cylindrical Roller Thrust Bearings

Cylindrical Roller Thrust Bearings

-

Cold Drawn Seamless Steel Pipe

Cold Drawn Seamless Steel Pipe