LSAW Steel Pipe

Application

LSAW steel pipe is mainly used for gas and oil transportation pipelines such as petroleum and natural gas delivery pipeline both on land and in the sea, city pipe network, water-coal-slurry pipeline in mining projects, high voltage power transmission line, etc. It is also suitable for steel structures of wind power system, bridge and high speed railway.

Our product meets the requirements of “west to east natural gas transmission project” which is a large and important project for natural gas transmission in China”. Our LSAW steel tubes can replace imported products in China and are exported to many countries as well.

Our LSAW steel pipe is mainly made of Q235B or Q345B steel material and complies with the standard of API5L GR.B. The tube end can be plain or bevel. Surface treatment such as paint spraying, 3PE anticorrosion, oil applying, hot-dip galvanizing, electric galvanizing and ink antirust coating are applied in our longitudinal seam steel tube.

Parameters

Length: SRL and DRL

Outside Diameter: 219 to 610mm

Wall Thickness: 5 to 20mm

Executive Standards: ASTM A53, ASTM A106, API 5L, APL 5CT, ASTM A519 and ASTM A213/A213M

Surface: black oil coating, galvanized coating, PE anti-corrosion coating

Way of Payment: T/T or L/C

Tests and Treatments

1.Inspection and Tests Conducted in LSAW Steel Pipe Production

Chemical composition test, mechanical property test, hydrostatic test, dimension testing, visual inspection, nondestructive inspection, water pressure test, bending test, crush testing, etc

2. Surface Treatment

PE, 3PE, FBE, black painting or uncoated

Links:https://www.globefindpro.com/products/79124.html

-

PE Coated Steel Pipe

PE Coated Steel Pipe

-

Oilfield Steel Pipe

Oilfield Steel Pipe

-

Thick Wall Seamless Steel Pipe

Thick Wall Seamless Steel Pipe

-

MB Series Spherical Roller Bearings

MB Series Spherical Roller Bearings

-

Single-Row Angular Contact Ball Bearings

Single-Row Angular Contact Ball Bearings

-

Thrust Ball Bearings

Thrust Ball Bearings

-

Galvanized Steel Pipe

Galvanized Steel Pipe

-

Tapered Roller Thrust Bearings

Tapered Roller Thrust Bearings

-

Double-Row Angular Contact Ball Bearings

Double-Row Angular Contact Ball Bearings

-

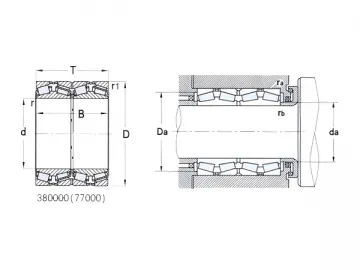

Four-Row Tapered Roller Bearings

Four-Row Tapered Roller Bearings

-

CNC Engraving Machine with Polished Effect

CNC Engraving Machine with Polished Effect

-

CNC Tapping Machine

CNC Tapping Machine