CNC Electro-hydraulic Press Brake

Jianghai is a professional bending machine provider. Our hydraulic components and CNC systems are imported overseas to ensure stable performance and high machining precision. The CNC electro-hydraulic press brake is extensively used in many industries to manufacture cars, ships, home appliances, kitchen wares, stainless steel, furniture, mechanical hardware, pipes and so forth. Our sheet metal bender is well received by customers in Europe, America, the Middle East, Southeast Asia, South Africa and other places.

Features of CNC Electro-Hydraulic Press Brake

1. The CNC hydraulic controlled metal bending brake boasts high accuracy and easy operation.

2. CNC System

1) Standard: DELEM DA56

2) Optional

a) DELEM: DA52, DA53, DA65W, DA66W, DA69W

b) CYBELEC: DNC60, DNC600S, DNC880S

3. Shaft Number

1) Standard: 3 1

a) Y1: Left cylinder moving up and down

b) Y2: Right cylinder moving up and down

c) X: Back gauge moving front and back

d) V: Workbench deflection compensation

2) Optional: 4 1, 5 1, 6 1, 8 1 or customization

4. The press brake is equipped with a workbench deflection compensation device, and its CNC system automatically controls the amount of deflection compensation.

5. Purchased from well-known brands, its hydraulic and electrical components are of standard specifications and easy to replace.

6. The standard back gauge consists of precise ball screw and linear guide-way, which effectively improves bending accuracy.

7. The frame features all welded construction, so as to guarantee machine precision and facilitate transportation and processing.

Press Brake CNC System

Technical Parameters

| Specification and model | Normal force | Maximum bending length | Distance between columns | Maximum opening height | Ram Stroke | Throat depth | Main motor power |

| 63/2500 | 630 | 2500 | 2060 | 420 | 200 | 300 | 7.5 |

| 63/3200 | 630 | 3200 | 2600 | 420 | 200 | 300 | 7.5 |

| 100/3200 | 1000 | 3200 | 2600 | 470 | 200 | 320 | 11 |

| 100/4000 | 1000 | 4000 | 3200 | 470 | 200 | 320 | 11 |

| 160/3200 | 1600 | 3200 | 2600 | 470 | 200 | 320 | 15 |

| 160/4000 | 1600 | 4000 | 3200 | 470 | 200 | 320 | 15 |

| 160/6000 | 1600 | 6000 | 4800 | 470 | 200 | 470 | 15 |

| 250/3200 | 2500 | 3200 | 2600 | 520 | 250 | 400 | 18.5 |

| 250/4000 | 2500 | 4000 | 3200 | 520 | 250 | 400 | 18.5 |

| 250/6000 | 2500 | 6000 | 4800 | 520 | 250 | 400 | 18.5 |

| 300/3200 | 3000 | 3200 | 2600 | 520 | 250 | 400 | 22 |

| 300/4000 | 3000 | 4000 | 3200 | 520 | 250 | 400 | 22 |

| 300/6000 | 3000 | 6000 | 4800 | 520 | 250 | 400 | 22 |

| 400/4000 | 4000 | 4000 | 3200 | 570 | 320 | 400 | 30 |

| 400/6000 | 4000 | 6000 | 4800 | 570 | 320 | 400 | 30 |

| 500/6000 | 5000 | 6000 | 4800 | 630 | 320 | 400 | 37 |

| 500/7000 | 5000 | 7000 | 5600 | 1050 | 320 | 600 | 37 |

| 600/6000 | 6000 | 6000 | 4800 | 650 | 320 | 400 | 45 |

| 800/6000 | 8000 | 6000 | 4800 | 820 | 400 | 500 | 37x2 |

| 800/8000 | 8000 | 8000 | 6100 | 820 | 400 | 500 | 37x2 |

| 1000/6000 | 10000 | 6000 | 4800 | 820 | 400 | 600 | 45x2 |

| 1000/8000 | 10000 | 8000 | 6100 | 820 | 400 | 600 | 45x2 |

| 1200/6000 | 12000 | 6000 | 4800 | 920 | 400 | 600 | 45x2 |

| 1200/8000 | 12000 | 8000 | 6100 | 920 | 400 | 600 | 45x2 |

| 1600/6000 | 16000 | 6000 | 4800 | 920 | 400 | 600 | 55x2 |

| 1600/8000 | 16000 | 8000 | 6100 | 920 | 400 | 600 | 55x2 |

| 2000/6000 | 20000 | 6000 | 4800 | 920 | 400 | 600 | 75x2 |

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#1d4ca6;','color:#fff;background:#4a4a4a','setclass');doget('/loadByJs.php?type=loadByReg&page=/1-3-press-brake-cnc-system/158905&start=start&end=end','setresult')}

Links:https://www.globefindpro.com/products/79138.html

-

Camaro Engraving Machine

Camaro Engraving Machine

-

Four Column Press

Four Column Press

-

4 Axis CNC Cutting Machine

4 Axis CNC Cutting Machine

-

Fiber Laser Cutting Machine

Fiber Laser Cutting Machine

-

Heavy-duty Swing Beam Shear

Heavy-duty Swing Beam Shear

-

Avant Garde Engraving Machine

Avant Garde Engraving Machine

-

Diva Engraving Machine

Diva Engraving Machine

-

Double-Row Tapered Roller Bearings

Double-Row Tapered Roller Bearings

-

SSAW Steel Pipe

SSAW Steel Pipe

-

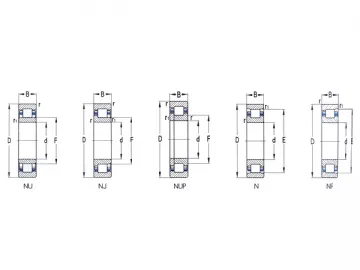

Single-Row Cylindrical Roller Bearings

Single-Row Cylindrical Roller Bearings

-

CA Series Spherical Roller Bearings

CA Series Spherical Roller Bearings

-

Double-Row Cylindrical Roller Bearings

Double-Row Cylindrical Roller Bearings