VMK-0088 Key Cutting Machine

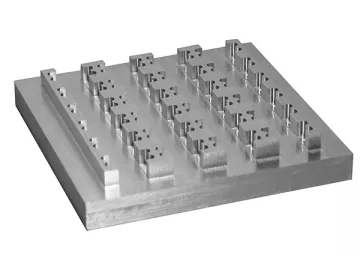

The VMK-0088 key cutting machine is designed to make flat keys and drill holes on lock cylinders. It has a compact electromechanical structure designed by CAD, making it easy to be incorporated into a production line in lockset manufacturing plant.

Advantages

1. The control system uses embedded 32-bit RISC microprocessor to achieve faster processing speed, which in return greatly enhancing the overall productivity.

2. The key cutting machine has a unique built-in drilling program to facilitate on-site programming, and the drilling process can be divided into several steps. For each step, the drilling depth, feed speed and return speed are all settable, while the distance between pin holes allows free adjustment.

3. Our key making machine is fitted with two motorized spindles with maximum speed of 24000rpm, and the implementation of stepless variable frequency speed regulation significantly improves machining precision and product smoothness. However, the noise level is much lower when compared with that of common motorized spindle, offering a quiet working place.

4. With the help of automatic pneumatic clamping device and foot switch, operators will find it very convenient to operate this CNC key machine. In addition, our product could at least fabricate 5000 pieces of common 6-hole keys per shift.

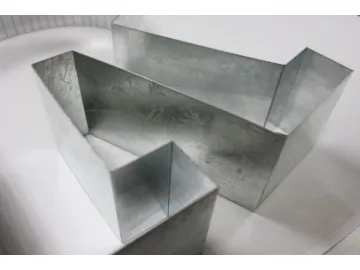

5. The software and clamping device can be changed to realize other functions, making our key cutting machine an extremely practical and economical tool on the market.

Technical Data

| Model | VMK-0088 | Unit |

| Positioning accuracy | ±0.03 | mm |

| Variable frequency main spindle motor | 1200×2 | W |

| Max. main spindle speed | 24000 | rpm |

| Cutting tool diameter | Ф3.175/4/6 | mm |

| Max. moving speed | 4 | m/min |

| Table size | 180×155 | mm |

| Max. stroke | 80×80 | mm |

| Overall dimensions | 700×650×850 | mm |

| Power supply | AC 220±10%/50 | V/Hz |

| Power consumption | 3 | kW |

| Weight | 125 | kg |

Links:https://www.globefindpro.com/products/79166.html

-

Electro-Hydraulic Press Brake

Electro-Hydraulic Press Brake

-

CNC Grooving Machine

CNC Grooving Machine

-

Roller Leveler

Roller Leveler

-

Cercon System Compatible Zirconia Block

Cercon System Compatible Zirconia Block

-

Super Translucency Coloring liquid for Zirconia Block

Super Translucency Coloring liquid for Zirconia Block

-

Shutze System Compatible Zirconia Block

Shutze System Compatible Zirconia Block

-

MEII-4840 Mold Engraving Machine

MEII-4840 Mold Engraving Machine

-

MEII-4242SQ Mold Engraving Machine

MEII-4242SQ Mold Engraving Machine

-

MEII-4242 Mold Engraving Machine

MEII-4242 Mold Engraving Machine

-

Heavy Duty Mechanical Shear

Heavy Duty Mechanical Shear

-

SE3230 Mold Engraving Machine

SE3230 Mold Engraving Machine

-

Precicut Plasma Cutting Machine

Precicut Plasma Cutting Machine