Single-Action Drawing Press

The single-action hydraulic drawing press can be used to draw, blank, bend, flange, extrude and form sheet metal, or even draw high-strength alloy plates. It is suitable for a variety of industries, including car, rolling stock, ship, motor, aircraft and power industry. Jianghai can supply 9 models of hydraulic drawing press whose maximum nominal force reaches 12500KN.

Features of Single-Action Drawing Press

1. With high processing precision and good rigidity, the hydraulic press adopts the welded-steel plate structure and hydraulic pre-tightening mode. Its rectangular guide rail is provided with four corners and eight sides.

2. Equipped with a two-way cartridge valve, its hydraulic system runs stably and enjoys long useful life.

3. Controlled by a PLC, its electrical system may be fitted with the digital stroke display, photo-electric safety device and moveable workbench. The machine supports double-action of the upper sliding block and lower hydraulic cushion. In addition, the hydraulic cushion can be changed into an ejector for drawing, if required.

4. To blank sheet metal, the machine should be mounted with a buffer device.

5. The single-action drawing press is able to set pressure or stroke. It has a delay function for maintaining pressure and the delay time is adjustable.

6. The working pressure and stroke can be adjusted within limits in accordance with technological requirements. With easy operation, the product can be controlled by buttons, and is provided with adjusting, manual and semi-automatic operating modes.

Technical Parameters of Single-Action Drawing Press

| Item | Unit | Model | |||

| YIH27-40 | YIH27-63 | YIH27-100 | |||

| Nominal force | KN | 400 | 630 | 1000 | |

| Hydraulic cushion force | KN | 190 | 190 | 400 | |

| Maximum working pressure of liquid | Mpa | 25 | 25 | 25 | |

| Sliding block stroke | mm | 400 | 400 | 600 | |

| Hydraulic cushion stroke | mm | 200 | 200 | 200 | |

| Maximum distance between sliding block and workbench | mm | 700 | 800 | 900 | |

| Sliding block speed | Descending with empty load | mm/s | 200 | 200 | 180 |

| Working | mm/s | 20 | 18 | 18 | |

| Return stroke | mm/s | 120 | 120 | 100 | |

| Workbench dimension | From left to right | mm | 500 | 570 | 720 |

| From front to back | mm | 460 | 500 | 580 | |

| hydraulic cushion dimension | From left to right | mm | 420 | 450 | 500 |

| From front to back | mm | 400 | 400 | 450 | |

| Motor power | KW | 5.5 | 7.5 | 11 | |

| Item | Unit | Model | |||

| YIH27-160 | YIH27-200 | YIH27-315 | |||

| Nominal force | KN | 1600 | 2000 | 3150 | |

| Hydraulic cushion force | KN | 400 | 630 | 1000 | |

| Maximum working pressure of liquid | Mpa | 25 | 25 | 25 | |

| Sliding block stroke | mm | 700 | 700 | 800 | |

| Hydraulic cushion stroke | mm | 200 | 300 | 300 | |

| Maximum distance between sliding block and workbench | mm | 1000 | 1100 | 1250 | |

| Sliding block speed | Descending with empty load | mm/s | 180 | 150 | 120 |

| Working | mm/s | 8-15 | 8-16 | 14-25 | |

| Return stroke | mm/s | 90 | 90 | 80 | |

| Workbench dimension | From left to right | mm | 1000 | 1000 | 1260 |

| From front to back | mm | 800 | 900 | 1160 | |

| hydraulic cushion dimension | From left to right | mm | 600 | 700 | 900 |

| From front to back | mm | 500 | 600 | 800 | |

| Motor power | KW | 22 | 30 | 44 | |

| Item | Unit | Model | |||

| YIH27-500 | YIH27-630 | YIH27-1250 | |||

| Nominal force | KN | 5000 | 6300 | 12500 | |

| Hydraulic cushion force | KN | 1600 | 2000 | 4000 | |

| Maximum working pressure of liquid | Mpa | 25 | 25 | 25 | |

| Sliding block stroke | mm | 900 | 900 | 900 | |

| Hydraulic cushion stroke | mm | 350 | 350 | 350 | |

| Maximum distance between sliding block and workbench | mm | 1500 | 1700 | 1800 | |

| Sliding block speed | Descending with empty load | mm/s | 100 | 100 | 80 |

| Working | mm/s | 14-25 | 12-25 | 12-25 | |

| Return stroke | mm/s | 70 | 70 | 70 | |

| Workbench dimension | From left to right | mm | 1400 | 1500 | 2400 |

| From front to back | mm | 1400 | 1500 | 2400 | |

| hydraulic cushion dimension | From left to right | mm | 1000 | 1100 | 1000 |

| From front to back | mm | 900 | 1000 | 1000 | |

| Motor power | KW | 75 | 90 | 150 | |

Note: Since our product is improved continuously, the parameters are subject to change without notice according to corresponding technical documents.

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#1d4ca6;','color:#fff;background:#4a4a4a','setclass')}

Links:https://www.globefindpro.com/products/79189.html

-

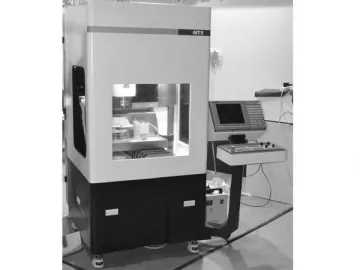

CM-MT5 Dental Milling Machine

CM-MT5 Dental Milling Machine

-

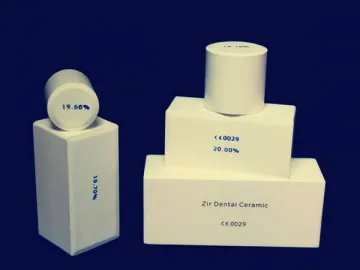

Kavo System Compatible Zirconia Block

Kavo System Compatible Zirconia Block

-

Sircona in Lab System Compatible Zirconia Block

Sircona in Lab System Compatible Zirconia Block

-

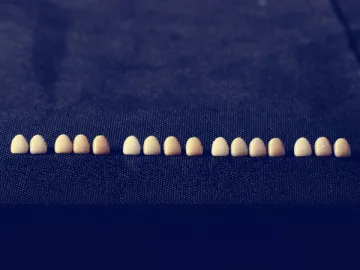

Dental Full Zirconia Crown

Dental Full Zirconia Crown

-

Hydraulic Rolling Shear

Hydraulic Rolling Shear

-

Zirconia Sintering Furnace

Zirconia Sintering Furnace

-

CAD/CAM System Compatible Zirconia Disc

CAD/CAM System Compatible Zirconia Disc

-

Wieland System Compatible Zirconia Block

Wieland System Compatible Zirconia Block

-

Zirkon Zahn Manual System Compatible Zirconia Block

Zirkon Zahn Manual System Compatible Zirconia Block

-

Universal Rolling Machine

Universal Rolling Machine

-

Guillotine Shear

Guillotine Shear

-

Dental Alloy

Dental Alloy