MH-6800 Brominated FR Masterbatch

The MH-6800 brominated FR masterbatch is a new carrier-free FR masterbatch with high FR efficiency. The proportion of Br-Sb is more than 95%. By adoption of low-temperature plasticized process, the environment-friendly and efficient masterbatch retains inherent FR characteristics. It does not produce toxic DBDO and DBDF during combustion.

This product has a higher addition rate and wider range of application, because it is carrier-free and utilizes compound additives. As a result, it is a generalized master batch that can be used in all kinds of plastics. Then, customers are allowed to design their formulation with much freedom.

Our brominated FR masterbatch has high whiteness, and it doesn't affect the color of manufactured goods. This sphere-shaped product has medium strength and hardness. It is widely used in PP, ABS, PA, EP, PBT, PET, PC, PE, HIPS, PVC, elastomer, and other materials.

Technical Parameters

| Item | Unit | Index |

| Appearance | - | White Granule |

| FR content | % | 94% min. |

| Volatile Matter | % | 0.5% max. |

| Decomposition Temperature | ℃ | 350 ℃ min. |

| Recommended Dosage | V-0(1.6mm) | PA(30%GF): 16-19PBT(30%GF): 12-14ABS:18-20 |

Packing and Storage

The brominated FR masterbatch is wrapped in a complex paper bag lined with PE bag. Its net weight is 25kg/bag. This product is stored at room temperature. It must be placed in a dry and ventilated room to prevent moisture.

Suggestion

1. Dry it before using after long-term storage.

2. Our customers had better understand the process conditions and properties of all products, and then choose the best process parameters for production before using

3. The above-mentioned data is normal laboratory values used only for reference. Specific dosage conforms to practical service conditions and required flammability rating.

Links:https://www.globefindpro.com/products/79385.html

-

Short Handle Floor Brush

Short Handle Floor Brush

-

Long Handle Scraper

Long Handle Scraper

-

MH-1800 Flame Retardant Masterbatch for PE

MH-1800 Flame Retardant Masterbatch for PE

-

MH-9800 Red Phosphorus Flame Retardant Masterbatch

MH-9800 Red Phosphorus Flame Retardant Masterbatch

-

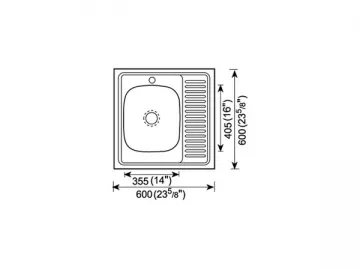

Single Bowl Single Drainer Sink

Single Bowl Single Drainer Sink

-

MH-2800 Flame Retardant Compound for PP Tube

MH-2800 Flame Retardant Compound for PP Tube

-

Plastic Sponge Squeegee

Plastic Sponge Squeegee

-

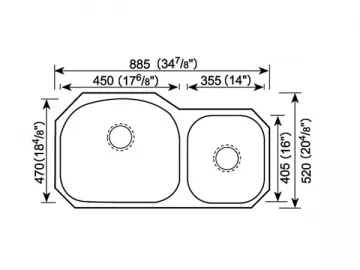

Undermount Double Bowl Sink

Undermount Double Bowl Sink

-

Triple Bowl Sink

Triple Bowl Sink

-

DBDPO/DECA Flame Retardant

DBDPO/DECA Flame Retardant

-

Round Dust Brush

Round Dust Brush

-

Long Handle Cleaning Brush

Long Handle Cleaning Brush