MH-2800 Flame Retardant Compound for PP Tube

The MH-2800 flame retardant compound for PP tube is made in accordance with MT558.1-2005 standards. It adopts PE80, PE100 grade HDPE as matrix resin. In addition, it utilizes high-performance composite fire retardant and special conductive carbon black as functional additives.

Our eco-friendly fire retardant is firstly dispersed through our dispersant, and then it is granulated by adoption of a twin-screw extruder. It is very easy to use our product, and no pollution is caused. Our flame retardant compound for PP tube is one of the best choices of those pipes for different purposes such as coal mine gas, ventilation, drainage, spraying, or anti-static dedicated pipes.

Product Features

1. The flame retardant compound for PP tube is anti-precipitation. It can be dispersed easily.

2. Its dose varies from 12 to 15%. There is no need to add antimony trioxide.

3. Dust pollution is not found. Our product can be directly applied in injection process, thus simplifying production process and also greatly reducing costs.

4. This product is fully compliant with new EU environmental standard (RoHS). It does not contain polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE).

5 The final density of retardants is approximately 1, while the other bromine-based flame retardant PE density ranges from 1.3-1.4.

6. Good mechanical properties allow the flame retardant compound to show good compatibility with resins. It is consistent with pure resins in almost all aspects of performance.

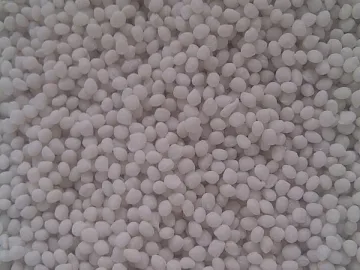

7. As a white particle, this product can be configured into a variety of colors.

Technical Index

| Items | Index | Test Method | Standard |

| Tensile Strength | MPa | GB1040-06-V50 | 13 min. |

| Bending Strength | MPa | GB9341-2008 | 12 min. |

| Flexural Modulus | MPa | GB9341-2008 | 325 min. |

| FR Properties | -- | MT558.1-2005(MT181) | Flaming Single/Six 10/18s max.Flameless Single/Six 60/120s max. |

| Melt Flow Rate | g/10min | GB3682-2000 (190 ℃, 5kg) | 0.3-0.8 |

| Surface Resistivity | Ω*m | MT558.1-2005(MT181) | 106 min. |

| Density | g/cm3 | GB/1033-86 | 0.98-1.03 |

| Applications | Coal mine gas/ventilation/drainage/spraying and antistatic pipe. | ||

Test Data of Users' Pipes: All the results of the extrusion technology, processing property, antistatic property and fire resistance have been certified by a special inspection agency.

| Items | Standard | Test result |

| Thermostability (200 ℃) | 20 min. | 81 |

| Longitudinal Retraction Rate (%) | 3 max. | 0.72 |

| Breaking Elongation (%) | 300 min. | 581 |

| Electrical Properties (Ω) | 106 min. | 6*103 |

| Tensile Strength (MPa) | 8.34 min. | 22.71 |

| Flattening Test (Pressed inside Coincidence) | No cracks | Pass |

| Flaming Combustion Time (s) | 10/18 max. | 2.15/8.31 |

| Flameless Combustion Time (s) | 60/120 max. | 1.21/9.26 |

| Hydrostatic Strength (1.93MPa/100h) | No leakage | Pass |

Recommended Parameters of Extrusion Process

| Items | Temperature (℃) | Items | Temperature (℃) | ||

| Materials | PE80 | PE100 | Materials | PE80 | PE100 |

| Machine Barrel | 150-165 | 175-185 | Melts | About 180 | About 195 |

| Mould | 170-175 | 190 | Temperature of Positioning Sleeve | 35-55 | 35-55 |

| Dies | 130-145 | 190 | Drying Temperature of Feeding Inlet | 95-110 | 95-110 |

Storage

The flame retardant compound for PP tube must be dried and stored at room temperature to prevent moisture. In case of long-term storage, it should be also dried before use.

After-Sales Service

We can help customers conduct initial production, and also give technical guidance. Based on customer requirements, we can dispatch technicians for trial production.

Packing

Our flame retardant compound is packed in a complex paper bag lined with PE bag. Its net weight is 25kg/bag.

Links:https://www.globefindpro.com/products/79391.html

-

MH-3860 HBCD-free Flame Retardant Masterbatch for XPS

MH-3860 HBCD-free Flame Retardant Masterbatch for XPS

-

Two in One Carpet Extractor

Two in One Carpet Extractor

-

Sofa Cleaner

Sofa Cleaner

-

Pressure Washer with Hose

Pressure Washer with Hose

-

Low Noise Wet and Dry Vacuum Cleaner

Low Noise Wet and Dry Vacuum Cleaner

-

Telescopic Rod

Telescopic Rod

-

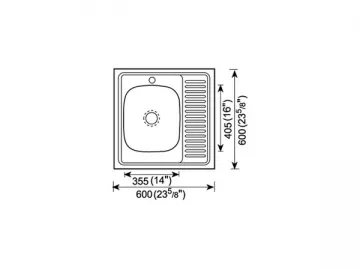

Single Bowl Single Drainer Sink

Single Bowl Single Drainer Sink

-

MH-9800 Red Phosphorus Flame Retardant Masterbatch

MH-9800 Red Phosphorus Flame Retardant Masterbatch

-

MH-1800 Flame Retardant Masterbatch for PE

MH-1800 Flame Retardant Masterbatch for PE

-

Long Handle Scraper

Long Handle Scraper

-

Short Handle Floor Brush

Short Handle Floor Brush

-

MH-6800 Brominated FR Masterbatch

MH-6800 Brominated FR Masterbatch