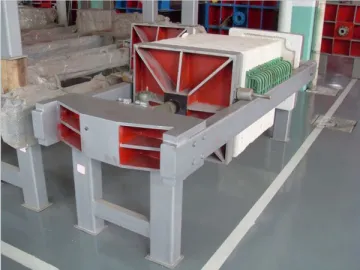

Main Characteristics

1. The SSB, SB series top discharge centrifuge is designed with reasonable structure, thus effectively eliminating the dirty corner. Surface of its structural parts has gone through a polished finish, thus being ultra smooth. The structural parts, fasteners and rotary drum are made from stainless steel.

2. The housing of our top discharge centrifuge adopts flip-open cover. Therefore, a sandwich layer between housing and drum can be thoroughly cleaned. Our product is also equipped with the feed pipe, wash pipe, sight glass, and the lightening hole.

3. This product comes with online spray system which can clean many invisible internal parts such as the inner wall of housing, the surface of liquid storage tank, and the inner and outer surfaces of a rotary drum, etc. It can guarantee cleanliness requirements, and also conform to GMP standard.

4. With simple structure, this series of top discharge centrifuge can be used and maintained conveniently.

5. The general-purpose centrifugal apparatus gives a wide range of applications. It can be used for the separation of suspensions containing solid-phase granules. Also, it can act as a separator for fibrous materials.

6. In addition, our top discharge centrifuge can adopt a frequency converter for smooth startup and adjustable separation factor. It also utilizes non-contact dynamic braking system and anti-static belt drive.

7. The whole structure is sealed, and its sealing elements adopt silicone rubber or viton. This airtight product gives strong resistance to explosion. It can be applied in places where there are toxic, flammable or explosive materials.

8. The use of nitrogen protection system makes sure that the interior of the centrifugal machine is isolated from external air.

9. Crystalline grains are not easily broken.

Optional Configurations

1. Spray cleaning system

2. Nitrogen protection system

3. Base and other external structural components are made from stainless steel.

4. Optional stainless steel materials are provided in accordance with the requirements of users for anticorrosion of the separated materials. They include the SUS304/316, 316L,321, titanium, and more.

5. Neither base chassis nor shock pad is available.

6. Drive and Brake

1) Explosion-proof motor or ordinary motor Frequency converter Dynamic braking

2) Electromagnetic speed-regulation motor Friction type manual brake

Technical Parameters | Item | SSB/SB600 |

| Drum | Diameter (mm) | 600 |

| | Wall Thickness (mm) | 5 |

| | Volume (L) | 45 |

| | Load Limit (kg) | 75 |

| | Rotation Speed (r/min) | 1500 |

| Separation Factor (w2r/g) | 860 |

| Motor Power (kW) | 3 |

| Weight (kg) | 980 |

| Dimension (mm)(L × W × H) | 1410 × 1140 × 800 |

| Item | SSB/SB800 |

| Drum | Diameter (mm) | 800 |

| | Wall Thickness (mm) | 6/8 |

| | Volume (L) | 100 |

| | Load Limit (kg) | 135 |

| | Rotation Speed (r/min) | 1200/1500 |

| Separation Factor (w2r/g) | 645/1006 |

| Motor Power (kW) | 5.5/7.5 |

| Weight (kg) | 1500 |

| Dimension (mm)(L × W × H) | 1680 × 1300 × 980 |

| Item | SSB/SB1000 |

| Drum | Diameter (mm) | 1000 |

| | Wall Thickness (mm) | 8/10 |

| | Volume (L) | 140 |

| | Load Limit (kg) | 200 |

| | Rotation Speed (r/min) | 1000/1200 |

| Separation Factor (w2r/g) | 560/806 |

| Motor Power (kW) | 7.5/11 |

| Weight (kg) | 2000 |

| Dimension (mm)(L × W × H) | 2000 × 1550 × 1200 |

| Item | SSB/SB1200 |

| Drum | Diameter (mm) | 1200 |

| | Wall Thickness (mm) | 10/12 |

| | Volume (L) | 280 |

| | Load Limit (kg) | 380 |

| | Rotation Speed (r/min) | 800/1050 |

| Separation Factor (w2r/g) | 620/740 |

| Motor Power (kW) | 11/15 |

| Weight (kg) | 3000 |

| Dimension (mm)(L × W × H) | 2260 × 1765 × 1300 |

| Item | SSB/SB1250 |

| Drum | Diameter (mm) | 1250 |

| | Wall Thickness (mm) | 12 |

| | Volume (L) | 310 |

| | Load Limit (kg) | 420 |

| | Rotation Speed (r/min) | 960/1050 |

| Separation Factor (w2r/g) | 645/770 |

| Motor Power (kW) | 15/18.5 |

| Weight (kg) | 3200 |

| Dimension (mm)(L × W × H) | 2260 × 1765 × 1350 |