GQ Series Tubular Centrifuge

Overview

The GQ series tubular centrifuge is a centrifugal machine that has an extremely high separation factor. It allows a particle with the minimum size of up to 1 micron to be separated. In particular, our product is fit for extracting, thickening and clarifying some materials which feature low content, fine particle size, highly corrosive media, and the small difference in specific gravities of solid-liquid phases, among others.

Our product is mainly used as a solid-liquid separator or a three-phase separator in various industries such as the food, chemicals, drinks, biopharmaceuticals, blood products, intermediates, and more. It is characterized by superb separation, high yield, small footprint, convenient operation, etc.

Classification

The tubular centrifuge is mainly categorized into the GQ clarification type and the GF separation type.

1. GQ Clarification Type

The GQ clarification type tubular centrifuge is basically used to handle the suspensions that are difficult to be separated. It is especially suitable for the solid-liquid separation of suspensions which feature low concentration, low particle size, and the tiny difference in specific gravities of solid-liquid phases.

High-density solids are gradually settled against the inner wall of the rotary drum, and then form a sediment layer. They will be discharged manually after the machine stops working. The clarified liquid flows to the top of the rotary drum, and then it is discharged from a liquid outlet.

Main Applications

1) For instance, this type of tubular centrifuge is ideal for clarifying of various oral liquids, chlorhexidine gluconate, malic acid, and menispermum dauricum DC.

2) It is also perfect for extracting of coal tar, graphite, various proteins, algae, and pectin.

3) In addition, this product is used for honey refining, blood separation, vaccine mycelium, and the sedimentation of various glucoses.

4) It can also purify the paints, dyes, various resins, and the rubber solution.

Technical Parameters

| Model | GQ45 | |

| Drum | Inner Diameter (mm) | 45 |

| Height (mm) | 280 | |

| Volume (L) | 0.45 | |

| Rotational Speed (r/min) | 50000 | |

| Separation Factor(w2r/g) | 90 | |

| Nozzle Diameter (mm) | 60000 | |

| Productivity (water flow) (kg/h) | 2, 3 | |

| Motor Power (kW) | 150 | |

| Weight(kg) | 0.75 | |

| Model | GQ75 | |

| Drum | Inner Diameter (mm) | 75 |

| Height (mm) | 450 | |

| Volume (L) | 2.7 | |

| Rotational Speed (r/min) | 21000 | |

| Separation Factor(w2r/g) | 300 | |

| Nozzle Diameter (mm) | 22500 | |

| Productivity (water flow) (kg/h) | 4, 6 | |

| Motor Power (kW) | 500 | |

| Weight(kg) | 1.5 | |

| Model | GQ105 | |

| Drum | Inner Diameter (mm) | 105 |

| Height (mm) | 730 | |

| Volume (L) | 6 | |

| Rotational Speed (r/min) | 19000 | |

| Separation Factor(w2r/g) | 480 | |

| Nozzle Diameter (mm) | 21000 | |

| Productivity (water flow) (kg/h) | 6, 8 | |

| Motor Power (kW) | 1500 | |

| Weight(kg) | 2.2 | |

| Model | GQ125 | |

| Drum | Inner Diameter (mm) | 125 |

| Height (mm) | 730 | |

| Volume (L) | 7.4 | |

| Rotational Speed (r/min) | 16000 | |

| Separation Factor(w2r/g) | 520 | |

| Nozzle Diameter (mm) | 18000 | |

| Productivity (water flow) (kg/h) | 5, 8, 9 | |

| Motor Power (kW) | 2000 | |

| Weight(kg) | 3.0 | |

| Model | GQ137 | |

| Drum | Inner Diameter (mm) | 137 |

| Height (mm) | 730 | |

| Volume (L) | 9 | |

| Rotational Speed (r/min) | 15000 | |

| Separation Factor(w2r/g) | 550 | |

| Nozzle Diameter (mm) | 17000 | |

| Productivity (water flow) (kg/h) | 6, 8, 10 | |

| Motor Power (kW) | 3000 | |

| Weight(kg) | 3.0 | |

| Model | GQ150 | |

| Drum | Inner Diameter (mm) | 142 |

| Height (mm) | 730 | |

| Volume (L) | 10 | |

| Rotational Speed (r/min) | 15000 | |

| Separation Factor(w2r/g) | 550 | |

| Nozzle Diameter (mm) | 17000 | |

| Productivity (water flow) (kg/h) | 8, 10, 12 | |

| Motor Power (kW) | 3000 | |

| Weight(kg) | 3.0 | |

2. GF Separation Type

The GF separation type tubular centrifuge is basically used for separating all sorts of emulsions that are difficult to deal with. In particular, it is suitable for the liquid-liquid separation with tiny difference of specific gravities of two phases, and the liquid-liquid-solid separator with very few impurities.

The high-density liquid forms an outer ring, while the low-density liquid forms an inner ring. Both liquids flow to the top of a rotary drum, and then they are discharged out of their respective liquid outlets. Very few solids are settled against the wall of the rotary drum. They will be discharged manually, after the machine stops working.

Main Applications

1) This tubular centrifuge can be utilized to deal with the transformer oil, turbine oil, lubricating oil, fuel oil, dye, grease, and more. It is also used for purifying a variety of micro powder and Span-80 material liquid.

2) Additionally, this type of product is proper for separating all kinds of oral liquids and medical liquids. It can also extract blood plasma from animal blood.

3) Other applications include the oil-water separation, sewage treatment, and the refining of soybean lecithin, etc.

Technical Parameters

| Model | GF45 | |

| Drum | Inner Diameter (mm) | 45 |

| Height (mm) | 280 | |

| Volume(L) | 0.45 | |

| Rotational Speed (r/min) | 50000 | |

| Separation Factor(w2r/g) | 60000 | |

| Nozzle Diameter (mm) | 2, 3 | |

| Productivity (water flow) (kg/h) | 150 | |

| Motor Power (kW) | 0.75 | |

| Weight(kg) | 90 | |

| Model | GF75 | |

| Drum | Inner Diameter (mm) | 75 |

| Height (mm) | 450 | |

| Volume(L) | 2.7 | |

| Rotational Speed (r/min) | 21000 | |

| Separation Factor(w2r/g) | 22500 | |

| Nozzle Diameter (mm) | 4, 6 | |

| Productivity (water flow) (kg/h) | 500 | |

| Motor Power (kW) | 1.5 | |

| Weight(kg) | 300 | |

| Model | GF105 | |

| Drum | Inner Diameter (mm) | 105 |

| Height (mm) | 730 | |

| Volume(L) | 6 | |

| Rotational Speed (r/min) | 19000 | |

| Separation Factor(w2r/g) | 21000 | |

| Nozzle Diameter (mm) | 6, 8 | |

| Productivity (water flow) (kg/h) | 1500 | |

| Motor Power (kW) | 2.2 | |

| Weight(kg) | 480 | |

| Model | GF125 | |

| Drum | Inner Diameter (mm) | 125 |

| Height (mm) | 730 | |

| Volume(L) | 7.4 | |

| Rotational Speed (r/min) | 16000 | |

| Separation Factor(w2r/g) | 18000 | |

| Nozzle Diameter (mm) | 5, 8, 9 | |

| Productivity (water flow) (kg/h) | 2000 | |

| Motor Power (kW) | 3.0 | |

| Weight(kg) | 520 | |

| Model | GF137 | |

| Drum | Inner Diameter (mm) | 137 |

| Height (mm) | 730 | |

| Volume(L) | 9 | |

| Rotational Speed (r/min) | 15000 | |

| Separation Factor(w2r/g) | 17000 | |

| Nozzle Diameter (mm) | 6, 8, 10 | |

| Productivity (water flow) (kg/h) | 3000 | |

| Motor Power (kW) | 3.0 | |

| Weight(kg) | 550 | |

| Model | GF150 | |

| Drum | Inner Diameter (mm) | 142 |

| Height (mm) | 730 | |

| Volume(L) | 10 | |

| Rotational Speed (r/min) | 15000 | |

| Separation Factor(w2r/g) | 17000 | |

| Nozzle Diameter (mm) | 8, 10, 12 | |

| Productivity (water flow) (kg/h) | 3000 | |

| Motor Power (kW) | 3.0 | |

| Weight(kg) | 550 | |

Links:https://www.globefindpro.com/products/79536.html

-

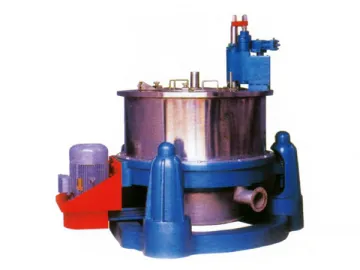

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

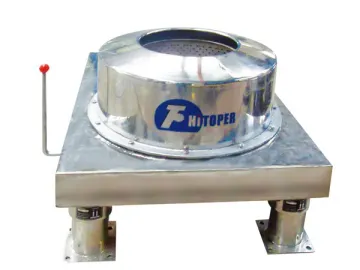

PS Series Manual Top Discharge Centrifuge

PS Series Manual Top Discharge Centrifuge

-

Multi Bag Filter

Multi Bag Filter

-

Rotary Disc Vacuum Filter

Rotary Disc Vacuum Filter

-

LW Series Decanter Centrifuge

LW Series Decanter Centrifuge

-

SD Series Bag Lifting Centrifuge

SD Series Bag Lifting Centrifuge

-

Sofa Suite and Table

Sofa Suite and Table

-

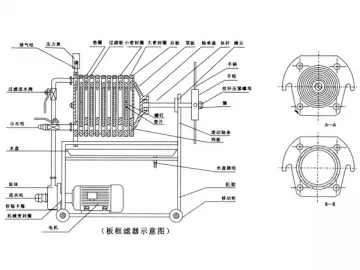

Stainless Steel Plate and Frame Filter Press

Stainless Steel Plate and Frame Filter Press

-

Automatic Filter Press

Automatic Filter Press

-

Hydraulic Compressing Filter Press

Hydraulic Compressing Filter Press

-

Single Sofa

Single Sofa

-

DNY Series Belt Filter Press with Thickening Function

DNY Series Belt Filter Press with Thickening Function