LW Series Decanter Centrifuge

Structure and Features

1. The LW series decanter centrifuge is a horizontal type spiral discharge system. It is a kind of continuously-operating sedimentation equipment.

2. Both rotary drum and helix rotate at high speed. The feedstock continuously enters the inner cylinder of the helix from a feed pipe. After acceleration, it will be sent to the rotary drum. Under the action of centrifugal force, the solids are settled against the wall of the rotary drum, and then form a sediment layer.

The deposited solids will be continuously sent to one tapered end of the rotary drum by helix. After being dried and dehydrated, they will be discharged out of a slag-discharging outlet. The liquid will spill out of the rotary drum through an overflow port, and then it is discharged through a liquid outlet.

3. During full-speed operation, the decanter centrifuge can conduct different working procedures such as continuous feeding, sedimentation, separation, washing, discharge, and more.

4. This product features compact structure, continuous operation, and stable running. Other prominent characteristics include great production capacity, convenient maintenance, and strong adaptability to separated materials, etc.

Applications

This series of decanter centrifuge can be used to separate the suspensions with the concentration range from 2 to 40%, and the solid-phase particle size of over 0.005mm. It is widely applied in industries such as chemicals, light industry, pharmaceuticals, food, environmental protection, and more.

Main Technical Parameters

| Model | LW230 | |

| Structure Type | Counter flow type | |

| Rotating Drum | Diameter (mm) | 700-920 |

| Length-to-Diameter Ratio | 3-4 | |

| Rotating Speed (r/min) | 4800 | |

| Separation Factor(w2r/g) | 3400 | |

| Processing Capacity of Admixtures (m3/h) | 0.5-1 | |

| Motor Power (kW) | 7.5 | |

| Total Weight (kg) | 800-1150 | |

| Model | LW355 | |

| Structure Type | Counter flow type | |

| Rotating Drum | Diameter (mm) | 860-1460 |

| Length-to-Diameter Ratio | 2.42-4.11 | |

| Rotating Speed (r/min) | 3500 | |

| Separation Factor(w2r/g) | 2500 | |

| Processing Capacity of Admixtures (m3/h) | 2-8 | |

| Motor Power (kW) | 18.5 5.5 | |

| Total Weight (kg) | 1800-2130 | |

| Model | LW450 | |

| Structure Type | Counter flow type | |

| Rotating Drum | Diameter (mm) | 1350-1800 |

| Length-to-Diameter Ratio | 3-4 | |

| Rotating Speed (r/min) | 3000 | |

| Separation Factor(w2r/g) | 2300 | |

| Processing Capacity of Admixtures (m3/h) | 6-20 | |

| Motor Power (kW) | 30 11 | |

| Total Weight (kg) | 2360-2730 | |

| Model | LW630 | |

| Structure Type | Counter flow type | |

| Rotating Drum | Diameter (mm) | 1900-2500 |

| Length-to-Diameter Ratio | 3-4 | |

| Rotating Speed (r/min) | 2200 | |

| Separation Factor(w2r/g) | 1700 | |

| Processing Capacity of Admixtures (m3/h) | 10-30 | |

| Motor Power (kW) | 30 15 | |

| Total Weight (kg) | 4800-5140 | |

| Model | LW710 | |

| Structure Type | Counter flow type | |

| Rotating Drum | Diameter (mm) | 1800-2500 |

| Length-to-Diameter Ratio | 2.5-3.5 | |

| Rotating Speed (r/min) | 1800 | |

| Separation Factor(w2r/g) | 1300 | |

| Processing Capacity of Admixtures (m3/h) | 15-45 | |

| Motor Power (kW) | 37 18.5 | |

| Total Weight (kg) | 5750-6350 | |

Ordering Instructions

1. Raw Material

Parts in touch with feedstock can be optionally made from carbon steel, stainless steel, titanium alloy, and more.

2. Wear-Resistant Treatment

The helix can adopt optional materials such as the wear-resistant sprayed materials, hard alloy sheets, and the corundum ceramic sheets. The slag discharging outlet can be installed with a hard alloy sleeve or a corundum ceramic sleeve.

3. Structure

Optional structure of our decanter centrifuge includes the counter flow type, parallel flow type, and the three-phase separation type.

4. Speed Regulation

Speed of the rotary drum is steplessly adjustable, and the helix differential can be adjusted at random.

5. Bearing Lubrication

Options include the grease lubrication, dilute oil lubrication, and the dilute-oil forced circulation and lubrication.

6. Safety Protection

Our product has the excessive vibration protection, the online inspection of bearing temperature, the display and overheating protection, and the motor overheating protection.

7. Compliant with GMP Standard or the Special Requirements of Users

Links:https://www.globefindpro.com/products/79542.html

-

SD Series Bag Lifting Centrifuge

SD Series Bag Lifting Centrifuge

-

Hotel Bedroom Furniture

Hotel Bedroom Furniture

-

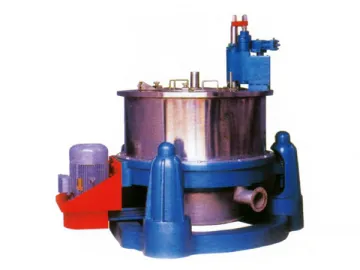

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

-

Lobby Sofa and Table

Lobby Sofa and Table

-

Membrane Filter Press

Membrane Filter Press

-

Rotary Disc Vacuum Filter

Rotary Disc Vacuum Filter

-

Multi Bag Filter

Multi Bag Filter

-

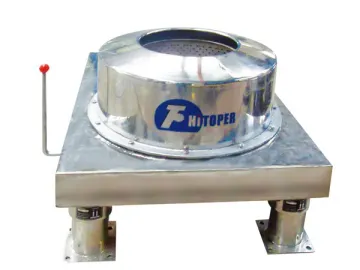

PS Series Manual Top Discharge Centrifuge

PS Series Manual Top Discharge Centrifuge

-

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

GQ Series Tubular Centrifuge

GQ Series Tubular Centrifuge

-

Sofa Suite and Table

Sofa Suite and Table