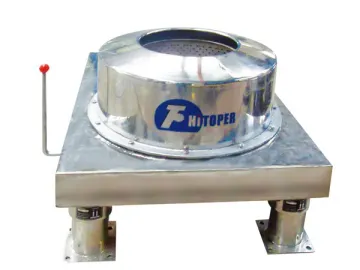

SD Series Bag Lifting Centrifuge

Features and Applications

The SD series bag lifting centrifuge is based on the SS series top discharge product. This product has numerous advantages such as the rapid discharge, improved production efficiency, and the significant reduction of labor intensity. In addition, it gives convenience for cleaning a filter bag, and also avoids end-product pollution and scattering caused by manual discharge.

Our bag lifting centrifuge is suitable for the separation of suspensions which feature the high-looseness solids, moderate particle size, and low-viscosity liquid. It is widely applied in industries including the chemicals, pharmaceuticals, food, light industry, mining, environmental protection, and more. The separator centrifuge is designed in compliance with GMP standard.

Structure and Principle

A motor drives a drum to rotate at a high speed. Feedstock is added in the drum from a top feed pipe. It is close to the wall of a drum with the support of centrifugal force. Then, liquid will be discharged through filter clothes and filter holes, while solids will stay in the drum.

After our bag lifting centrifuge stops working, its cover will be opened. Then, the lock pin of liquid blocking plate will be loosened. By adoption of a lifting device, the liquid blocking plate and the filter bag with filter residues will be sent to the place for discharging materials. After that, a special hook is loosened. One end of a filter bag is opened to make filter cakes fall down automatically.

Ordering Information

We have designed a variety of bag lifting centrifuges to meet different separation requirements. While ordering an order, our customers had better confirm the following.

1. Base

The suspended centrifugal apparatus can be equipped with a base, or without a base due to the adoption of a shock absorber.

2. Raw Material

Raw material of the bag lifting centrifuge can be stainless steel, titanium, carbon steel, plastic lining, or other substances.

3. Driving Method

The use of an electromagnetic motor can meet the requirements for the medium-speed or low-speed feed and the high-speed separation. It can be adapted to the separation of numerous materials. A frequency-control flameproof motor can be applied in those places where strong explosion resistance is required. An ordinary or flameproof motor is usually adopted if speed regulation is not required.

Technical Parameters

| Type | SD800 | |

| Drum | Diameter (mm) | 800 |

| Height (mm) | 360 | |

| Volume (L) | 90 | |

| Load Limit (kg) | 120 | |

| Rotation Speed (r/min) | 1200 | |

| Separation Factor (w2r/g) | 860 | |

| Motor Power (kW) | 7.5 | |

| Weight (kg) | 1350 | |

| Dimension (mm)(L × W × H) | 1740 × 1380 × 1100 | |

| Type | SD1000 | |

| Drum | Diameter (mm) | 1000 |

| Height (mm) | 400 | |

| Volume (L) | 140 | |

| Load Limit (kg) | 150 | |

| Rotation Speed (r/min) | 1000 | |

| Separation Factor (w2r/g) | 640 | |

| Motor Power (kW) | 11 | |

| Weight (kg) | 2300 | |

| Dimension (mm)(L × W × H) | 1950 × 1560 × 1200 | |

| Type | SD1200 | |

| Drum | Diameter (mm) | 1200 |

| Height (mm) | 450 | |

| Volume (L) | 230 | |

| Load Limit (kg) | 240 | |

| Rotation Speed (r/min) | 800 | |

| Separation Factor (w2r/g) | 600 | |

| Motor Power (kW) | 18.5 | |

| Weight (kg) | 3400 | |

| Dimension (mm)(L × W × H) | 2370 × 1600 × 1200 | |

| Type | SD1500 | |

| Drum | Diameter (mm) | 1500 |

| Height (mm) | 450 | |

| Volume (L) | 360 | |

| Load Limit (kg) | 400 | |

| Rotation Speed (r/min) | 600 | |

| Separation Factor (w2r/g) | 500 | |

| Motor Power (kW) | 22 | |

| Weight (kg) | 5000 | |

| Dimension (mm)(L × W × H) | 2645 × 2221 × 1700 | |

Links:https://www.globefindpro.com/products/79543.html

-

Hotel Bedroom Furniture

Hotel Bedroom Furniture

-

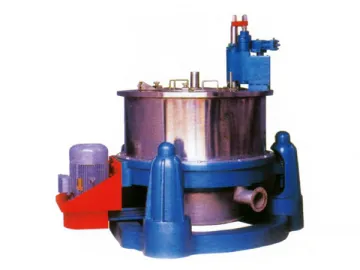

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

-

Lobby Sofa and Table

Lobby Sofa and Table

-

Membrane Filter Press

Membrane Filter Press

-

PD Series Bag Lifting Centrifuge

PD Series Bag Lifting Centrifuge

-

LW Series Decanter Centrifuge

LW Series Decanter Centrifuge

-

Rotary Disc Vacuum Filter

Rotary Disc Vacuum Filter

-

Multi Bag Filter

Multi Bag Filter

-

PS Series Manual Top Discharge Centrifuge

PS Series Manual Top Discharge Centrifuge

-

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

SGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

GQ Series Tubular Centrifuge

GQ Series Tubular Centrifuge