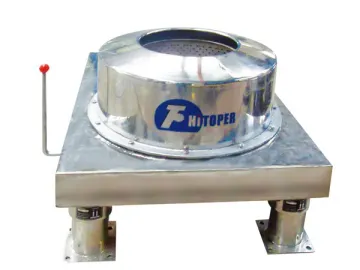

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

Structure and Characteristics

1. The PGZ series centrifuge with scraper is an automatic bottom discharge system. It is also a kind of batch filtration apparatus. Feedstock is added into a rotary drum from the top of our machine.

2. With the support of centrifugal force, liquid will be discharged through filter media. Solids will stay in the drum. They will be removed with a scraper out of the bottom of our product, after the rotary drum slows down.

3. The automatic bottom discharge centrifuge with scraper is characterized by stable running, convenient operation, and more.

4. Its program can be preset in accordance with operating requirements. Our equipment can automatically complete different working procedures such as feeding, separation, washing, dewatering, discharge, etc. It can realize both long-distance and short-distance operation.

5. Other remarkable features include superior separating effect, great handling capacity, and high degree of automation.

6. This series of centrifuge gets rid of traditional suspension legs. It is configured with a heavy plate and a highly-elastic shock absorber. A base is not needed in our product.

7. In addition, a PG series manual bottom discharge centrifuge with scraper is also provided.

Applications

This product can be used to separate the suspensions which contain solid-phase granules of at least 0.01mm. It can act as an ideal food dehydrator for dewatering the starch, vitamins, and the antibiotics. In metal industry, our product is perfect for dewatering of different mineral powder such as copper, zinc, aluminum, etc.

Main Technical Parameters

| Type | PGZ/PG800 | |

| Rotating Drum | Diameter (mm) | 800 |

| Volume (L) | 100 | |

| Load Limit (kg) | 140 | |

| Max. Speed (r/min) | 1500 | |

| Separation Factor(w2r/g) | 1008 | |

| Motor Power (kW) | 11 | |

| Limit Height of Opening the Cover (mm) | 2000 | |

| Total Weight (kg) | 3000 | |

| Dimensions (mm)(L × W × H) | 1800×1200×1670 | |

| Type | PGZ/PG1000 | |

| Rotating Drum | Diameter (mm) | 1000 |

| Volume (L) | 150 | |

| Load Limit (kg) | 200 | |

| Max. Speed (r/min) | 1200 | |

| Separation Factor(w2r/g) | 806 | |

| Motor Power (kW) | 15 | |

| Limit Height of Opening the Cover (mm) | 2250 | |

| Total Weight (kg) | 4000 | |

| Dimensions (mm)(L × W × H) | 2050×1500×2000 | |

| Type | PGZ/PG1250 | |

| Rotating Drum | Diameter (mm) | 1250 |

| Volume (L) | 280 | |

| Load Limit (kg) | 400 | |

| Max. Speed (r/min) | 900 | |

| Separation Factor(w2r/g) | 567 | |

| Motor Power (kW) | 18.5 | |

| Limit Height of Opening the Cover (mm) | 2700 | |

| Total Weight (kg) | 5000 | |

| Dimensions (mm)(L × W × H) | 2350×1650×2450 | |

| Type | PGZ/PG1250-NA | |

| Rotating Drum | Diameter (mm) | 1250 |

| Volume (L) | 400 | |

| Load Limit (kg) | 540 | |

| Max. Speed (r/min) | 1000 | |

| Separation Factor(w2r/g) | 700 | |

| Motor Power (kW) | 22 | |

| Limit Height of Opening the Cover (mm) | 3000 | |

| Total Weight (kg) | 5500 | |

| Dimensions (mm)(L × W × H) | 2400×1700×2920 | |

| Type | PGZ/PG1600 | |

| Rotating Drum | Diameter (mm) | 1600 |

| Volume (L) | 900 | |

| Load Limit (kg) | 1200 | |

| Max. Speed (r/min) | 850 | |

| Separation Factor(w2r/g) | 647 | |

| Motor Power (kW) | 45 | |

| Limit Height of Opening the Cover (mm) | 3500 | |

| Total Weight (kg) | 8500 | |

| Dimensions (mm)(L × W × H) | 3000×2200×3300 | |

Order Notice

1. Raw Material

Optional materials in touch with feedstock include stainless steel, carbon steel, rubber lining, plastic lining, titanium alloy, and more.

2. Driving Method

Options include the drive of an electromagnetic speed-regulation motor, the variable frequency drive of an ordinary motor or an explosion-proof motor, and more.

3. Braking Method

Available braking methods include the mechanical braking, electric braking, and more.

4. Method of Opening the Cover

Customers can choose a hydraulic, pneumatic, electrical, or mechanical balancer.

5. Base

This series of centrifuge has no base.

6. Electrical Control Mode

The electrical control mode can be semi-automatic, full-automatic, or PLC control, etc.

7. Our product can be designed and manufactured in compliance with GMP standard.

Links:https://www.globefindpro.com/products/79548.html

-

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

-

Lobby Sofa and Table

Lobby Sofa and Table

-

Membrane Filter Press

Membrane Filter Press

-

PD Series Bag Lifting Centrifuge

PD Series Bag Lifting Centrifuge

-

Cold Drawn Aluminum Tube

Cold Drawn Aluminum Tube

-

Aluminum Multi-port Extrusion

Aluminum Multi-port Extrusion

-

Hotel Bedroom Furniture

Hotel Bedroom Furniture

-

SD Series Bag Lifting Centrifuge

SD Series Bag Lifting Centrifuge

-

LW Series Decanter Centrifuge

LW Series Decanter Centrifuge

-

Rotary Disc Vacuum Filter

Rotary Disc Vacuum Filter

-

Multi Bag Filter

Multi Bag Filter

-

PS Series Manual Top Discharge Centrifuge

PS Series Manual Top Discharge Centrifuge