DYX Series High Pressure Belt Filter Press

Design Features

1. The DYX series high pressure belt filter press adopts the working principle of a general belt press. It is developed by our company with over 20 years manufacturing experience. This product is a kind of dewatering equipment for lumps, strips and slag. Due to optimized structure and high degree of automation, it can offer ultra high dewatering efficiency.

2. This series of high pressure belt filter press mainly consists of the feed unit, main engine drive, frame, multiple high-pressure rollers, high-pressure filter belts, tension device, filter-belt washing device, deviation adjusting device, discharge unit, and the electrical control system.

3. The multi-roll filter belt press can offer a strong squeezing force, which allows dried materials to have low water content. Due to high degree of automation, it can offer continuous operation, automatic feeding, and automatic discharge. As a result, our machine features high efficiency, easy operation, convenient maintenance, and great reduction of labor cost.

Working Principle

Our high pressure belt filter press can realize deep dehydration effect through the following processes.

1. A conveyor delivers sludge to a feed hopper of the high pressure belt filter press.

2. A high-pressure filter belt can send quantitative sludge to multiple high-pressure rollers from a feed unit with stepless speed control.

3. After being squeezed and dried, the sludge will be scraped from the high-pressure filter belt, and then fall into a storage hopper.

4. The high-pressure filter belt will be washed with high-pressure water. Then, it will return to the position of feed unit for continuous operation.

Applications

As an automatic pressurising dehydrator, our product gives a wide range of applications in various industries. It is used to dewater the sludge, fruit, vegetables, potatoes, various Chinese herbal medicines, and more.

Technical Parameters

| Type | DYX500 |

| Belt Width (mm) | 500 |

| Speed (m/min) | 2-9 |

| Power (kW) | 5.5 |

| Washing Pressure (MPa) | 1-1.5 |

| Water Consumption (m³/h) | 1 |

| Dimension (L×W×H) (mm) | 4650 × 1900 × 2450 |

| Weight (t) | 5.5 |

| Type | DYX1000 |

| Belt Width (mm) | 1000 |

| Speed (m/min) | 2-9 |

| Power (kW) | 7.5 |

| Washing Pressure (MPa) | 1-1.5 |

| Water Consumption (m³/h) | 1.5 |

| Dimension (L×W×H) (mm) | 4650 × 2400 × 2450 |

| Weight (t) | 7.5 |

| Type | DYX1500 |

| Belt Width (mm) | 1500 |

| Speed (m/min) | 2-9 |

| Power (kW) | 11 |

| Washing Pressure (MPa) | 1-1.5 |

| Water Consumption (m³/h) | 2 |

| Dimension (L×W×H) (mm) | 4650 × 2900 × 2450 |

| Weight (t) | 9 |

| Type | DYX2000 |

| Belt Width (mm) | 2000 |

| Speed (m/min) | 2-9 |

| Power (kW) | 15 |

| Washing Pressure (MPa) | 1-1.5 |

| Water Consumption (m³/h) | 2 |

| Dimension (L×W×H) (mm) | 4650 × 3400 × 2450 |

| Weight (t) | 10.5 |

Links:https://www.globefindpro.com/products/79549.html

-

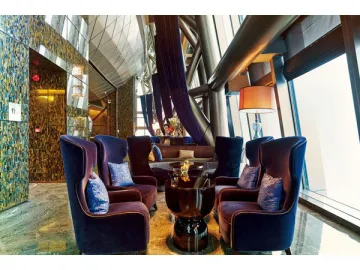

Lobby Sofa and Table

Lobby Sofa and Table

-

Membrane Filter Press

Membrane Filter Press

-

PD Series Bag Lifting Centrifuge

PD Series Bag Lifting Centrifuge

-

Cold Drawn Aluminum Tube

Cold Drawn Aluminum Tube

-

Aluminum Multi-port Extrusion

Aluminum Multi-port Extrusion

-

Straight Copper Pipe

Straight Copper Pipe

-

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

Hotel Bedroom Furniture

Hotel Bedroom Furniture

-

SD Series Bag Lifting Centrifuge

SD Series Bag Lifting Centrifuge

-

LW Series Decanter Centrifuge

LW Series Decanter Centrifuge

-

Rotary Disc Vacuum Filter

Rotary Disc Vacuum Filter

-

Multi Bag Filter

Multi Bag Filter