Structure and Characteristics

1. The PD series bag lifting centrifuge is a kind of sealed filtration equipment with intermittent operation. It allows feedstock to be added into the top opening of a drum. Under the action of centrifugal force, liquid will be discharged through filter media, and solids will stay in the rotary drum. After that, both liquid blocking plate and filter bag will be lifted and sent to the destination for discharging materials.

2. Prominent advantages of the equipment include smooth startup, adjustable separation factor, and great capacity. In addition, we have taken into account many practical problems that may occur during operation. After repeated experiments, this machine features rapid discharge and high safety.

3. This series of bag lifting centrifuge abandons the traditional suspension legs. It can be installed without a base. In addition, this product adopts a heavy plate and a highly-elastic shock absorber. It gives much convenience for installation.

4. The cover of the bag lifting centrifuge can be fully opened. Its motor has overload, overheating, and overcurrent protection. Considerate design can guarantee a safe operation when our client utilizes this product.

Applications

1. This series of product is perfect for the separation of suspensions with the solids content of at least 0.01mm. It is especially suitable for the filtration of toxic or flammable materials.

2. Our bag lifting centrifuge is broadly applicable in industries such as the chemicals, pharmaceuticals, and the light industry, etc. For instance, it can deal with the gypsum, thiamine, soda, rubber additives, dyes, plastics, sugar and vitamin. It is also an ideal dewatering machine for copper, zinc, aluminum and other mineral powder.

Main Technical Parameters | Model | PD800 |

| Drum | Diameter (mm) | 800 |

| | Operating Capacity (L) | 115 |

| | Load Limit (kg) | 155 |

| | Rotational Speed (r/min) | 1500 |

| Separation Factor(w2r/g) | 1008 |

| Motor Power (kW) | 7.5 |

| Limit Height of Opening the Cover (mm) | 2280 |

| Total Weight (kg) | 1600/1800 |

| Dimensions (mm)(L x W x H) | 1800x1050x1140 |

| Model | PD1000 |

| Drum | Diameter (mm) | 1000 |

| | Operating Capacity (L) | 170 |

| | Load Limit (kg) | 230 |

| | Rotational Speed (r/min) | 1200 |

| Separation Factor(w2r/g) | 806 |

| Motor Power (kW) | 11 |

| Limit Height of Opening the Cover (mm) | 2590 |

| Total Weight (kg) | 2300/2800 |

| Dimensions (mm)(L x W x H) | 2030x1300x1220 |

| Model | PD1200 |

| Drum | Diameter (mm) | 1200 |

| | Operating Capacity (L) | 250 |

| | Load Limit (kg) | 340 |

| | Rotational Speed (r/min) | 800 |

| Separation Factor(w2r/g) | 431 |

| Motor Power (kW) | 11 |

| Limit Height of Opening the Cover (mm) | 2850 |

| Total Weight (kg) | 2800/3200 |

| Dimensions (mm)(L x W x H) | 2300x1500x1350 |

| Model | PD1250 |

| Drum | Diameter (mm) | 1250 |

| | Operating Capacity (L) | 280 |

| | Load Limit (kg) | 400 |

| | Rotational Speed (r/min) | 950 |

| Separation Factor(w2r/g) | 631 |

| Motor Power (kW) | 18.5 |

| Limit Height of Opening the Cover (mm) | 2850 |

| Total Weight (kg) | 3800/4200 |

| Dimensions (mm)(L x W x H) | 2350x1500x1370 |

| Model | PD1500 |

| Drum | Diameter (mm) | 1500 |

| | Operating Capacity (L) | 500 |

| | Load Limit (kg) | 650 |

| | Rotational Speed (r/min) | 850 |

| Separation Factor(w2r/g) | 607 |

| Motor Power (kW) | 30 |

| Limit Height of Opening the Cover (mm) | 3400 |

| Total Weight (kg) | 4800/5200 |

| Dimensions (mm)(L x W x H) | 2900x1900x1575 |

| Model | PD1800 |

| Drum | Diameter (mm) | 1800 |

| | Operating Capacity (L) | 600 |

| | Load Limit (kg) | 800 |

| | Rotational Speed (r/min) | 700 |

| Separation Factor(w2r/g) | 494 |

| Motor Power (kW) | 37 |

| Limit Height of Opening the Cover (mm) | 3700 |

| Total Weight (kg) | 7200/7800 |

| Dimensions (mm)(L x W x H) | 3170x2540x1770 |

Ordering Information

1. Raw Material

Optional materials in contact with feedstock are provided. They include the stainless steel, carbon steel, rubber lining, plastic lining, titanium alloy, and the Hastelloy, etc.

2. Driving Method

A general motor or explosion-proof motor can be driven by a clutch, an electromagnetic motor, a general motor, or an explosion-proof motor under frequency control.

3. Braking Method

Our bag lifting centrifuge adopts mechanical braking, electric braking, or other methods.

4. Base

The machine can be equipped with a base, or without a base.

5. This product can be designed and manufactured in full compliance with GMP standard.

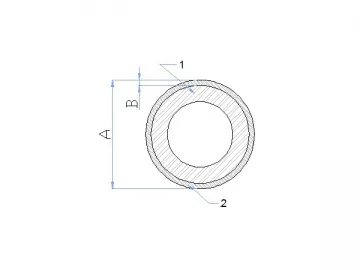

Cold Drawn Aluminum Tube

Cold Drawn Aluminum Tube

Aluminum Multi-port Extrusion

Aluminum Multi-port Extrusion

Straight Copper Pipe

Straight Copper Pipe

ZPYGS55 Rotary Tablet Press

ZPYGS55 Rotary Tablet Press

Filter Cloth

Filter Cloth

Brazing Material Coated Aluminum Tube

Brazing Material Coated Aluminum Tube

Membrane Filter Press

Membrane Filter Press

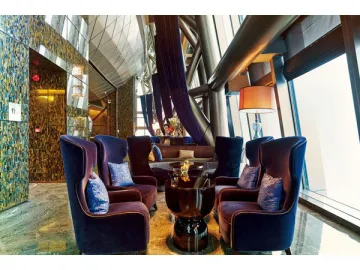

Lobby Sofa and Table

Lobby Sofa and Table

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

Hotel Bedroom Furniture

Hotel Bedroom Furniture

SD Series Bag Lifting Centrifuge

SD Series Bag Lifting Centrifuge