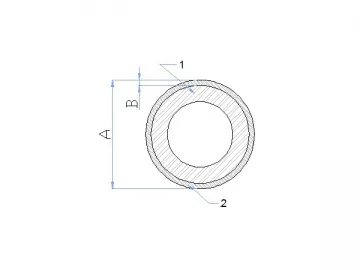

Cold Drawn Aluminum Tube

The cold drawn aluminum tube is commonly seen in heating, ventilation, air conditioning and refrigerating industry. This light weight aluminium product can be applied in a standard heat exchanger made of mechanical expansion pipes.

Our aluminum tube performs well in outstanding quality, heat conduction and fluid transmission. It is well received in automotive heat exchanger, air conditioner and refrigeration industry.

The tubular product has certain limitations, which depends on its alloy composition and the ratio of outer diameter and wall thickness. We provide cold drawn aluminum tube of different dimension and alloy composition, to meet various demands.

Dimension

Outer diameter: 4mm-90mm

Wall thickness: 0.3mm-5mm

Features

1. Light weight

2. Outstanding thermal and electrical conductivity

3. Easy to shape or bend

4. Good corrosion resistance

5. High recyclability

6. Great dimensional precision

7. Small tolerance

Application

Vehicle air conditioner, household air conditioner, high-low pressure connecting pipeline for engineering machinery, water tank tube, etc.

Alloy Designation

1. 3xxx series, such as 3003, 3103

2. 5xxx series, such as 5052, 5049, 5086

3. 6xxx series, such as 6063, 6061

| Material | State | Round Tube | |||

| Straight Tube | Coil Pipe | ||||

| Outer Diameter | Wall Thickness | Outer Diameter | Wall Thickness | ||

| 1060(L2) | R(H112) | 13~150 | 1~20 | - | - |

| M(O) | 13~150 | 1~20 | 4~20 | 0.4-2 | |

| H14 | 4-40 | 0.4-10 | 4~20 | 0.4-2 | |

| 1050(L3) | R(H112) | 13~150 | 1~20 | - | - |

| M(O) | 13~150 | 1~20 | 4~20 | 0.4-2 | |

| H14 | 4-60 | 0.4-10 | 4~20 | 0.4-2 | |

| 1100(L5-1) | R(H112) | 13~150 | 1~20 | - | - |

| M(O) | 13~150 | 1~20 | 4~20 | 0.4-2 | |

| H14 | 4-60 | 0.4-10 | 4~20 | 0.4-2 | |

| 3A21(LF21) | R(H112) | 13~150 | 1~20 | - | - |

| M(O) | 4~150 | 1~20 | 4~19 | 0.3-2 | |

| H12 | 4-60 | 0.3-10 | 5~19 | 0.3-2 | |

| H14 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| H18 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| 3103 | H112 | 13~150 | 1~20 | - | - |

| O | 4~150 | 0.3~20 | 4~20 | 0.3-2 | |

| H12 | 4-60 | 0.3-10 | 5~19 | 0.3-2 | |

| H14 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| H18 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| 3003 | H112 | 13~150 | 1~20 | - | - |

| O | 4~150 | 0.3~20 | 4~20 | 0.3-2 | |

| H12 | 4-60 | 0.3-10 | 5~19 | 0.3-2 | |

| H14 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| H18 | 4-60 | 0.3-10 | 4~20 | 0.3-2 | |

| JC9888 | T6 | 50~100 | 10~20 | - | - |

| 5049 | R(H112) | - | - | - | - |

| M(O) | 8-40 | 1-3 | - | - | |

| 5052 | R(H112) | - | - | - | - |

| M(O) | 8-40 | 1-10 | - | - | |

| H34 | 10-40 | 1-7 | - | - | |

| 5086 | R(H112) | - | - | - | - |

| M(O) | 10-60 | 1-10 | - | - | |

| H34 | 10-40 | 1-7 | - | - | |

| 6063(LD31) | R(H112) | 13~100 | 1~30 | 28 | 2.5 |

| M(O) | 6-100 | 0.5~30 | - | - | |

| T4 | 6-100 | 0.5~30 | - | - | |

| T6 | 6-100 | 0.5~30 | - | - | |

| T83 | 6-60 | 0.8~10 | - | - | |

| 6061(LD30) | R(H112) | 20-100 | 1.5-30 | - | - |

| M(O) | 6-100 | 0.5-30 | - | - | |

| T4 | 6-100 | 0.5-30 | - | - | |

| T6 | 6-100 | 0.5-30 | - | - | |

Links:https://www.globefindpro.com/products/79553.html

-

Aluminum Multi-port Extrusion

Aluminum Multi-port Extrusion

-

Straight Copper Pipe

Straight Copper Pipe

-

ZPYGS55 Rotary Tablet Press

ZPYGS55 Rotary Tablet Press

-

Filter Cloth

Filter Cloth

-

Brazing Material Coated Aluminum Tube

Brazing Material Coated Aluminum Tube

-

ZP45 Rotary Tablet Press

ZP45 Rotary Tablet Press

-

PD Series Bag Lifting Centrifuge

PD Series Bag Lifting Centrifuge

-

Membrane Filter Press

Membrane Filter Press

-

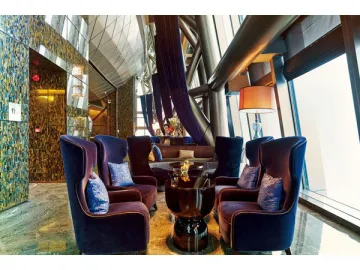

Lobby Sofa and Table

Lobby Sofa and Table

-

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

-

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

-

Hotel Bedroom Furniture

Hotel Bedroom Furniture