Aluminum Multi-port Extrusion

The aluminum multi-port extrusion, also known as parallel flow microchannel flat tube, is a kind of highly refined tubular product. It is mainly applied in condensers and evaporators with R134-A refrigerating fluid. Due to superior quality and large internal surface area, the product does well in heat conduction and is ideal for efficient heat exchangers. Our aluminum multi-port extrusion is commonly seen in auto motive heat exchangers, air conditioners, refrigerating machines, etc.

According to the development trend, R744(CO2) will serve as a new type freezing medium, which puts forward higher demands for multi-port extrusion. That is to say, the tube should be provided with optimized size, higher pressure resistance and better thermal conductivity. Therefore, our product can be sprayed with zinc and covered with brazing flux coating.

The aluminum multi-port extrusion is available of different dimension and alloy composition, so as to satisfy your requirements. We support coil packaging or fixed-scale cutting with chipless closing in.

Features

1. Light weight

2. Good thermal and electrical conductivity

3. Corrosion resistance

4. Great shaping and bending performance

5. Reaching ROHS standard

6. High recyclability

7. Qualified surface finish

8. Small deviation range

9. Outstanding pressure resistance

Alloy Designation

1. 1xxx series, such as 1100, 1050, 1060, 1070

2. 3xxx series, such as 3102

Specification

1. Width: 6mm-40mm

2. Height: 0.8mm-8.0mm

3. Wall Thickness: More than 0.12

4. Hole number: 2-35

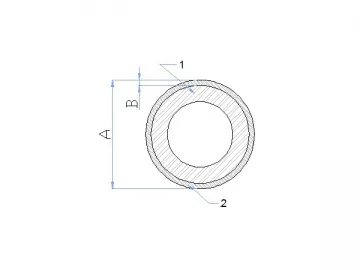

Sectional Drawing and Parameter of Special Product

Technical Parameters

| No. | Dimension | Allowable deviation | Material | State |

| A | 6 ~40 | ±0.05 max. | 1050/1050A/1060/1060A/1070/1100/3102 | H112 |

| B | 0.8 ~8.0 | ±0.03 max. | ||

| C | 0.40 min | ±0.08 max. | ||

| D | 0.20 min | ±0.05 max. | ||

| E | 0.25 min | ±0.05 max. | ||

| Length | Customization (sizing and preform) | |||

Links:https://www.globefindpro.com/products/79554.html

-

Straight Copper Pipe

Straight Copper Pipe

-

ZPYGS55 Rotary Tablet Press

ZPYGS55 Rotary Tablet Press

-

Filter Cloth

Filter Cloth

-

Brazing Material Coated Aluminum Tube

Brazing Material Coated Aluminum Tube

-

ZP45 Rotary Tablet Press

ZP45 Rotary Tablet Press

-

Mechanical Compressing Filter Press

Mechanical Compressing Filter Press

-

Cold Drawn Aluminum Tube

Cold Drawn Aluminum Tube

-

PD Series Bag Lifting Centrifuge

PD Series Bag Lifting Centrifuge

-

Membrane Filter Press

Membrane Filter Press

-

Lobby Sofa and Table

Lobby Sofa and Table

-

DYX Series High Pressure Belt Filter Press

DYX Series High Pressure Belt Filter Press

-

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper

PGZ Series Automatic Bottom Discharge Centrifuge with Scraper