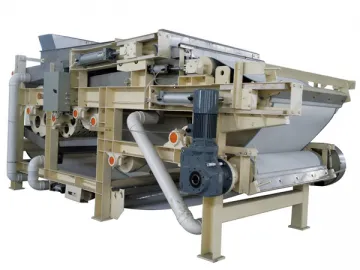

DY Series Belt Filter Press

Introduction

The DY series belt filter press is developed by HI-TOPER and Chinese research institutes on basis of the introduction of advanced technology from abroad. The new filter equipment is used extensively for sludge dewatering in various industries such as the chemicals, oil refining, metallurgy, papermaking, tanning, food, coal washing, urban sewage treatment, printing and dyeing, etc.

This belt filter press can offer numerous advantages such as continuous operation, easy use, convenient maintenance, and high degree of automation. Therefore, it is an ideal sludge dewatering machine.

Components

This machine is mainly composed of the drive, frame, sludge distribution system, filter belt, tensioner, automatic deviation adjusting system, filter belt washing system, sludge scraper, gravity dewatering zone, wedge dewatering zone, the squeezing and dewatering zone, and more.

Superiority

1. Our belt filter press adopts state-of-the-art technology from Austria, and its exterior is streamlined.

2. Due to high-stiffness structure, this machine can provide smooth operation and low noise.

3. The belt filter press is configured with advanced concentration-pretreatment equipment, thus offering superb flocculation effect and low operating cost.

4. The gravity dewatering zone is equipped with a high-performance distributing device, so that sludge can be distributed uniformly. This device can also extend the service life of filter belt.

5. The use of ultra-long gravity dewatering zone and wedge dewatering zone allows sludge to be dewatered thoroughly. The sludge does not spill from the squeezing zone.

6. Rollers are arranged in order. The squeezing and dewatering roller has high diameter ratio and superb dewatering effect. Therefore, it is an energy-saving and efficient dewatering system with large production capacity.

7. The belt filter press features high degree of automation in a continuous production process from feeding to filter cake discharge. It can be designed with PLC interface upon request, which gives convenience for PC centralized control.

8. Its power transmission adopts mechanical speed regulation or stepless speed regulation, so it gives large regulation scope and wide adaptability.

9. A dependable backwashing device is utilized to guarantee the dehydration effect of filter belt.

10. The use of pneumatic tension device and automatic correction device makes sure that the filter belt can work normally and safely.

11. Additionally, our belt filter press comes with infrared safety protection and comprehensive emergency safety stopping device.

12. In view of different materials, our equipment can be configured with various types of high-precision filter belt.

Main Technical Parameters

| Series | Effective Width of Press (mm) | Filter Speed (m/min) | Length (mm) | Width (mm) | Height (mm) | Weight (t) | Main Power (kW) | Capacity (m³/h) | Cleaning Water Consumption (L/min) |

| 500 | 500 | 0.5~12 | 4500 | 1450 | 2250 | 2.3 | 1.1 | 1~5 | 30~50 |

| 1000 | 1000 | 0.5~12 | 4500 | 1950 | 2250 | 2.8 | 1.5 | 4~10 | 60~80 |

| 1500 | 1500 | 0.5~12 | 4500 | 2450 | 2350 | 3.5 | 2.2 | 7~12 | 80~100 |

| 2000 | 2000 | 0.5~12 | 4500 | 2950 | 2350 | 3.9 | 2.2 | 10~18 | 120~140 |

| 2500 | 2500 | 0.5~12 | 4500 | 3450 | 2400 | 5.0 | 3.0 | 15~20 | 140~160 |

| 3000 | 3000 | 0.5~12 | 4500 | 3950 | 2400 | 5.8 | 3.0 | 18~25 | 160~180 |

Selection Guidelines

1. The equipment model can be chosen with view to the viscosity, throughput, solid particle size, solid bulk density, and the solid-liquid ratio.

2. The flow components can be selected in accordance with PH value of materials. Filter media are optional on basis of the solid particle diameter and the temperature of materials.

3. This series of belt filter press is applicable for treating sludge or other sludge-like materials.

4. Please conduct a bench-scale test for a material which has never been used within this industry.

Installation Drawing of DY Series Belt Filter Press

DY Series Belt Filter Press

Links:https://www.globefindpro.com/products/79567.html

-

Cast Iron Filter Press

Cast Iron Filter Press

-

ZP5A/7A/9A Rotary Tablet Press

ZP5A/7A/9A Rotary Tablet Press

-

T-A Ⅲ Single Punch Tablet Press

T-A Ⅲ Single Punch Tablet Press

-

ZPY27B Rotary Tablet Press

ZPY27B Rotary Tablet Press

-

ZPT21/ZPT25 Rotary Tablet Press

ZPT21/ZPT25 Rotary Tablet Press

-

Diatomite Filter

Diatomite Filter

-

ZPY120 Rotary Tablet Press

ZPY120 Rotary Tablet Press

-

DDY-Ⅱ Single Punch Tablet Press

DDY-Ⅱ Single Punch Tablet Press

-

ZP37A Rotary Tablet Press

ZP37A Rotary Tablet Press

-

Filter Plate

Filter Plate

-

Mechanical Compressing Filter Press

Mechanical Compressing Filter Press

-

ZP45 Rotary Tablet Press

ZP45 Rotary Tablet Press