ZPYG45 Rotary Tablet Press

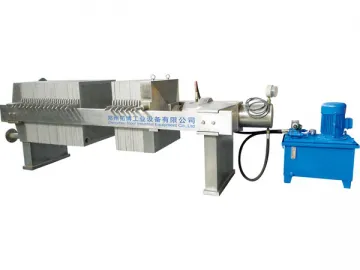

Main Application

The ZPYG45 is our newly developed sub-speed rotary tablet press. With considerable productivity and high pressure, it is applied to fuse granulated raw materials together to form round, ring or irregular shape tablets with diversified specification in many industries, including pharmacy, industrial engineering, food, electron and so on.

Features

1. The rotary tablet press enjoys the maximum output of 200,000 tablets per hour, which is comparable with that of a high speed tablet compression machine.

2. Reaching GMP standard, it makes use of stainless steel peripheral housing and internal table top. After special treatment, its turret is non-toxic, smooth and wear-resistant.

3. The machine does well in high power and pressure. Fitted with 2 pre-pressing tracks, it runs smoothly and can press powders that are hard to form.

4. A forced feeding device is used to enhance flowability and filling performance of powders and guarantee the accuracy of feeding.

5. To prevent damage to the rotary tablet press, an overload protection device is employed. In case there is pressure overload, a warning light will flash and the machine will automatically stop.

6. This pharmaceutical machine adopts frequency control to guarantee easy operation, good security and high precision.

7. Its network communication function is able to set the address of device in line with your requirements, and upload data according to the communication protocol, which realizes managing the operation and output of rotary tablet press.

8. Due to the reliable centralized lubricating system, all lubricating points are fully lubricated.

9. On the basis of humanized design concept, the machine is easy to clean and maintain.

10. As an individual component, its drive system is separately placed within the worm gear case under the main body, so as to avoid cross contamination and ensure full lubrication of the transmission system, reducing noise and abrasion.

11. With the help of the specific structure and our utility model patent, the lower track and lower pinch roller can be replaced or maintained easily.

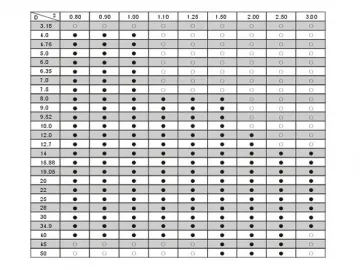

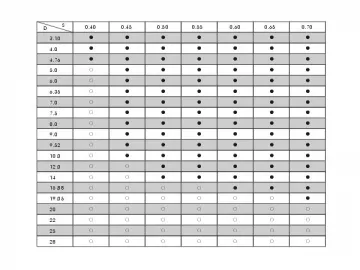

Technical Parameters

| Die (sets) | 45 |

| Maximum pressure (kN) | 100 |

| Maximum diameter of tablet (mm) | Φ 13 |

| Maximum filling depth (mm) | 17 |

| Maximum thickness of tablet (mm) | 8 |

| Rotational speed of turret (r/min) | 5 ~ 36 |

| Maximum production capacity (tablets/hour) | 200,000 |

| Motor (kW) | 5.5 |

| Weight of main machine (kg) | 1800 |

| Floor area (mm) | 1100 × 940 |

| Height (including hopper) (mm) | 1755 |

| Height (excluding hopper) (mm) | 1500 |

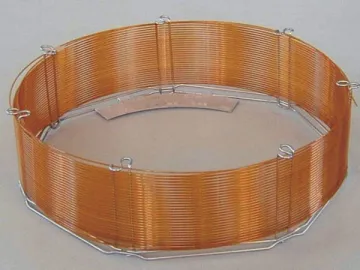

Sample

Links:https://www.globefindpro.com/products/79579.html