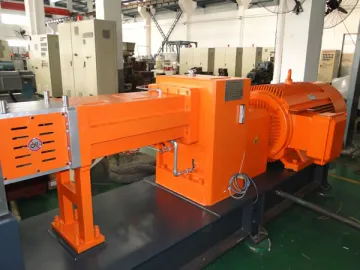

TSC-52/120 Screw Extruder

In the TSC-52/120 series two-stage screw extruder, the material will be mixed by the twin screw extrusion unit, and then extruded down to the single screw extruder. At the stage two, material will be mixed at high pressure, followed by the pelletizing at a lowered temperature. The extruders in the two stages are installed in a “T” shape.

At stage one, the material will be delivered, mixed, plastified and sheared. The whole process is conducted with no extrusion pressure caused by the extrusion dies. High temperature will be avoided due to the strong shearing, so the productivity is greatly enhanced. At the stage two, the extruder will cool the material, increase the pressure and complete the pelletizing of the material. The two extruder work together closely and more parameters can be adjusted for different purposes. The TSC-52/120 series two-stage screw extruder is suitable for the processing of materials like PVC-based cable sheath, various kinds of transparent materials, PE-related cross-linking materials, PE-based cable sheath and the some foam material for the shoe sole.

The highlighted part in the form below is the parameters of the TSC-52/120 two-stage screw extrusion facility. The rest part detailed the other models of the TSC series products. Custom products are available according to your requirements, such as those for production capacity and materials.

| Type | Diameter (mm) | L/D | Screw speed (r/min) | Power (kw) | Capacity (kg/h) | |

| TSC-52/120 | TSB-52 | 51.4 | 24~48 | 500 | 45 | 100~300 |

| SE-120 | 120 | 7~20 | 85 | 30~37 | ||

| TSC-52/150 | TSH-52 | 51.4 | 24~48 | 600 | 90 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/150 | TSB-65 | 62.4 | 24~48 | 500 | 75 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/180 | TSH-65 | 62.4 | 24~48 | 600 | 160 | 400~1000 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/180 | TSB-75 | 71 | 24~48 | 500 | 110 | 400~800 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/200 | TSH-75 | 71 | 24~48 | 600 | 250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

| TSC-95/200 | TSB-95 | 93 | 24~48 | 400 | 200~250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

Links:https://www.globefindpro.com/products/79745.html

-

LED Speed Limit Sign

LED Speed Limit Sign

-

ST-66-23W LED Street Light

ST-66-23W LED Street Light

-

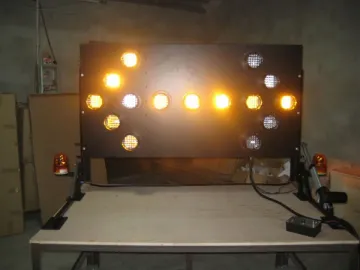

TA15H/TA25H Trailer Mounted Arrow Board

TA15H/TA25H Trailer Mounted Arrow Board

-

LED Traffic Warning Sign

LED Traffic Warning Sign

-

TSH-95 Screw Extruder

TSH-95 Screw Extruder

-

Vehicle Mounted Arrow Board

Vehicle Mounted Arrow Board

-

TSB-135 Screw Extruder

TSB-135 Screw Extruder

-

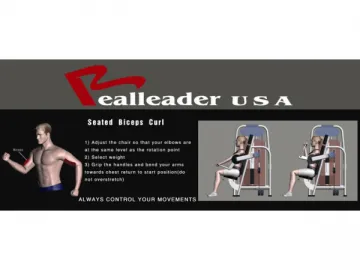

M7-1005 Seated Biceps Curl

M7-1005 Seated Biceps Curl

-

FW-1004 Seated Arm Curl

FW-1004 Seated Arm Curl

-

FW-1012 Adjustable Abdominal Bench

FW-1012 Adjustable Abdominal Bench

-

TSB-35 Screw Extruder

TSB-35 Screw Extruder

-

Rowing Machine

Rowing Machine