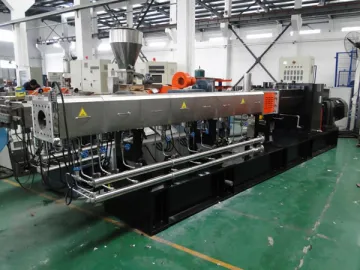

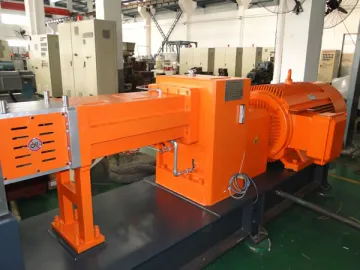

TSH-65 Screw Extruder

TSH-65

Chuangbo developed the high torque parallel co-rotating twin screw to expand the application range of our TSH series high torque twin screw extrusion unit. For example, the residence time of the material in the twin screw extrusion machine can be precisely controlled when processing some traditional wood-plastic composites or conducting reactive extrusions.

The form below showed the parameters of different products belonging to the TSH series twin screw extrusion equipment, while the highlighted part is for the TSH-65 high torque twin screw extruder. Custom products are available according to your requirements for production capacity, material, and so on.

| Model | Diameter (mm) | L/D | Screw speed (r/min) | Power (KW ) | Torque (N·m) | Specific torque (T/A3) | Capacity (kg/h) |

| TSH-25 | 26 | 32~60 | 400 | 7.5 | 86 | 8.1 | 5~35 |

| 600 | 11 | 84 | 7.9 | 5~55 | |||

| TSH-35 | 35.6 | 32~68 | 500 | 22 | 202 | 7.5 | 10~110 |

| 600 | 30 | 229 | 8.5 | 10~150 | |||

| TSH-40 | 41 | 32~68 | 500 | 37 | 339 | 8.3 | 110~200 |

| 600 | 45 | 344 | 8.4 | 135~225 | |||

| TSH-52 | 51.4 | 32~68 | 500 | 75 | 688 | 8.6 | 225~375 |

| 600 | 90 | 688 | 8.6 | 270~450 | |||

| TSH-65 | 62.4 | 32~68 | 500 | 132 | 1210 | 8.6 | 396~660 |

| 600 | 160 | 1222 | 8.7 | 480~800 | |||

| TSH-75 | 71 | 32~68 | 500 | 200 | 1834 | 8.5 | 600~1000 |

| 600 | 250 | 1910 | 8.8 | 750~1250 | |||

| TSH-85 | 81 | 32~68 | 500 | 280 | 2567 | 8.2 | 840~1400 |

| 600 | 350 | 2674 | 8.6 | 1050~1750 | |||

| TSH-95 | 93 | 32~68 | 500 | 450 | 4126 | 8.7 | 1350~2250 |

| 600 | 550 | 4202 | 8.9 | 1650~2750 | |||

| TSH-135 | 133 | 32~68 | 400 | 1000 | 11460 | 8.6 | 3000~5000 |

Scan QR to Read

Links:https://www.globefindpro.com/products/79753.html

Links:https://www.globefindpro.com/products/79753.html

Recommended Products

-

TSS-65 Extrusion Machine

TSS-65 Extrusion Machine

-

TSC-52/150 Screw Extruder

TSC-52/150 Screw Extruder

-

TSV-100 Extrusion Equipment

TSV-100 Extrusion Equipment

-

TSH-25 Screw Extruder

TSH-25 Screw Extruder

-

TSC-65/180 Screw Extruder

TSC-65/180 Screw Extruder

-

TSH-85 Screw Extruder

TSH-85 Screw Extruder

-

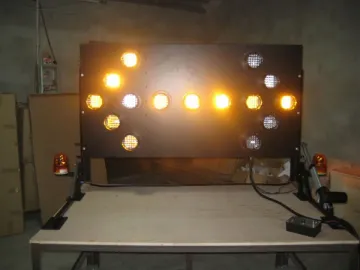

TA15W/TA25W Trailer Mounted Arrow Board

TA15W/TA25W Trailer Mounted Arrow Board

-

Vehicle Mounted Arrow Board

Vehicle Mounted Arrow Board

-

TSH-95 Screw Extruder

TSH-95 Screw Extruder

-

LED Traffic Warning Sign

LED Traffic Warning Sign

-

TA15H/TA25H Trailer Mounted Arrow Board

TA15H/TA25H Trailer Mounted Arrow Board

-

ST-66-23W LED Street Light

ST-66-23W LED Street Light

Hot Products