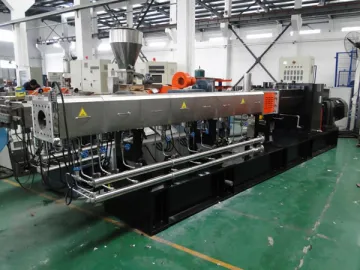

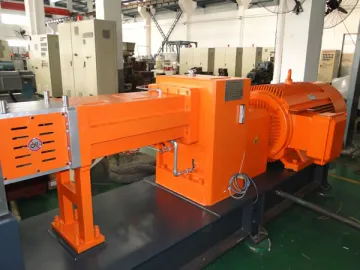

TSC-52/150 Screw Extruder

Like the other types of two-stage screw extruder, TSC-52/150 extrusion machine is mainly used for the mixing, modifying, and pelletizing of thermal sensitive materials such as the PVC cable sheath, XLPE, medical grade soft PVC material, EVA foam material for shoe sole, and low smoke zero halogen flame retardant material. The pelletizing techniques usually include hot material pelletizing with air cooling system, and decentration pelletizing with water spaying system, cool material strand palletizing and hot material water ring palletizing.

The form below showed the parameters of different types of TSC series products, while the highlighted part is for the TSC-52/150 two-stage screw extruder. Custom two-stage screw extrusion unit is also available according to your requirements for production capacity and materials.

| Type | Diameter (mm) | L/D | Screw speed (r/min) | Power (kw) | Capacity (kg/h) | |

| TSC-52/120 | TSB-52 | 51.4 | 24~48 | 500 | 45 | 100~300 |

| SE-120 | 120 | 7~20 | 85 | 30~37 | ||

| TSC-52/150 | TSH-52 | 51.4 | 24~48 | 600 | 90 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/150 | TSB-65 | 62.4 | 24~48 | 500 | 75 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/180 | TSH-65 | 62.4 | 24~48 | 600 | 160 | 400~1000 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/180 | TSB-75 | 71 | 24~48 | 500 | 110 | 400~800 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/200 | TSH-75 | 71 | 24~48 | 600 | 250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

| TSC-95/200 | TSB-95 | 93 | 24~48 | 400 | 200~250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

Links:https://www.globefindpro.com/products/79755.html

-

TSV-100 Extrusion Equipment

TSV-100 Extrusion Equipment

-

TSH-25 Screw Extruder

TSH-25 Screw Extruder

-

TSC-65/180 Screw Extruder

TSC-65/180 Screw Extruder

-

TSH-85 Screw Extruder

TSH-85 Screw Extruder

-

TSV-66 Extrusion Equipment

TSV-66 Extrusion Equipment

-

Standard LED Tube

Standard LED Tube

-

TSS-65 Extrusion Machine

TSS-65 Extrusion Machine

-

TSH-65 Screw Extruder

TSH-65 Screw Extruder

-

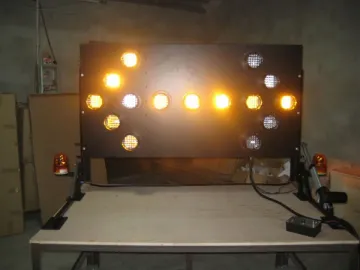

TA15W/TA25W Trailer Mounted Arrow Board

TA15W/TA25W Trailer Mounted Arrow Board

-

Vehicle Mounted Arrow Board

Vehicle Mounted Arrow Board

-

TSH-95 Screw Extruder

TSH-95 Screw Extruder

-

LED Traffic Warning Sign

LED Traffic Warning Sign