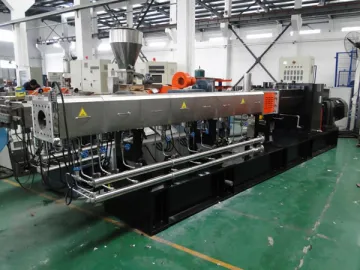

TSC-65/180 Screw Extruder

The TSC-65/180 two-stage screw extruder is based on the advanced foreign technologies, which has been remarkably renovated by us. The extrusion unit now is controlled by a PLC system, thus the automation level is really high and the mixing performance is quite satisfactory. We have added a range of handy functions to the machine, while the appearance and structure are also greatly optimized. We provide custom barrel structure according to customer’s requirements—you can choose integrated alloy barrel liner or split-type alloy barrel liner.

The integrated alloy barrel liner is forged as one piece, and meets higher technique requirements than the bimetal barrel does. The overall technique level of our two-stage screw extrusion machine reached that of our counterparts in Europe. Comparing to the traditional split-type bimetal barrel liner, our design has better wear-resistant performance, thus the service life is extended.

The parameters of our TSC-65/180 two-stage screw extruder are showed in the form below. The rest part is for the other models of TSC series products. Additionally, custom products are available according to your requirements.

| Type | Diameter (mm) | L/D | Screw speed (r/min) | Power (kw) | Capacity (kg/h) | |

| TSC-52/120 | TSB-52 | 51.4 | 24~48 | 500 | 45 | 100~300 |

| SE-120 | 120 | 7~20 | 85 | 30~37 | ||

| TSC-52/150 | TSH-52 | 51.4 | 24~48 | 600 | 90 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/150 | TSB-65 | 62.4 | 24~48 | 500 | 75 | 200~500 |

| SE-150 | 150 | 7~20 | 85 | 37~45 | ||

| TSC-65/180 | TSH-65 | 62.4 | 24~48 | 600 | 160 | 400~1000 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/180 | TSB-75 | 71 | 24~48 | 500 | 110 | 400~800 |

| SE-180 | 180 | 7~20 | 85 | 45~55 | ||

| TSC-75/200 | TSH-75 | 71 | 24~48 | 600 | 250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

| TSC-95/200 | TSB-95 | 93 | 24~48 | 400 | 200~250 | 700~1500 |

| SE-200 | 200 | 7~20 | 85 | 55~75 | ||

Links:https://www.globefindpro.com/products/79758.html

-

TSH-85 Screw Extruder

TSH-85 Screw Extruder

-

TSV-66 Extrusion Equipment

TSV-66 Extrusion Equipment

-

Standard LED Tube

Standard LED Tube

-

TSS-95 Extrusion Machine

TSS-95 Extrusion Machine

-

TM220W/TM320W Trailer Mounted VMS

TM220W/TM320W Trailer Mounted VMS

-

TSB-18 Screw Extruder

TSB-18 Screw Extruder

-

TSH-25 Screw Extruder

TSH-25 Screw Extruder

-

TSV-100 Extrusion Equipment

TSV-100 Extrusion Equipment

-

TSC-52/150 Screw Extruder

TSC-52/150 Screw Extruder

-

TSS-65 Extrusion Machine

TSS-65 Extrusion Machine

-

TSH-65 Screw Extruder

TSH-65 Screw Extruder

-

TA15W/TA25W Trailer Mounted Arrow Board

TA15W/TA25W Trailer Mounted Arrow Board