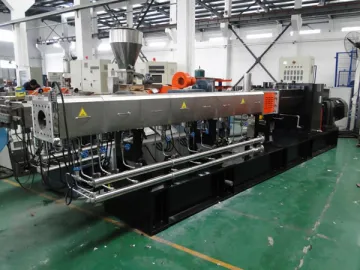

TSH-85 Screw Extruder

TSH series products including TSH-85 high torque twin screw extruder has been improved continuously. They now come with a number of advantages

1. Our latest design, as a national patent, has successfully merged the gear reducer and the torque distribution device.

2. The shafting and gear design has been optimized, leading to more than 30% improvement in terms of carrying capacity comparing with traditional design.

3. The service life of key transverse bearings is remarkably extended, reaching 20,000 hours or above.

4. Select metal was used for important gears in the twin screw extrusion equipment. The surface of the tooth is hardened (HRC: 58~65), while the precision degree reached level 6.

5. The bath-oiling device comes with compulsory recirculating cooling system, auxiliary spraying device, compulsory filtration system, and reliable oil supply system, so the lubrication system works just perfectly.

The parameters of our TSH-85 high torque twin screw extruder are showed in the form below. The rest part is for the other models of TSH series twin screw extrusion machine. Additionally, custom products are available according to your requirements.

| Model | Diameter (mm) | L/D | Screw speed (r/min) | Power (KW ) | Torque (N·m) | Specific torque (T/A3) | Capacity (kg/h) |

| TSH-25 | 26 | 32~60 | 400 | 7.5 | 86 | 8.1 | 5~35 |

| 600 | 11 | 84 | 7.9 | 5~55 | |||

| TSH-35 | 35.6 | 32~68 | 500 | 22 | 202 | 7.5 | 10~110 |

| 600 | 30 | 229 | 8.5 | 10~150 | |||

| TSH-40 | 41 | 32~68 | 500 | 37 | 339 | 8.3 | 110~200 |

| 600 | 45 | 344 | 8.4 | 135~225 | |||

| TSH-52 | 51.4 | 32~68 | 500 | 75 | 688 | 8.6 | 225~375 |

| 600 | 90 | 688 | 8.6 | 270~450 | |||

| TSH-65 | 62.4 | 32~68 | 500 | 132 | 1210 | 8.6 | 396~660 |

| 600 | 160 | 1222 | 8.7 | 480~800 | |||

| TSH-75 | 71 | 32~68 | 500 | 200 | 1834 | 8.5 | 600~1000 |

| 600 | 250 | 1910 | 8.8 | 750~1250 | |||

| TSH-85 | 81 | 32~68 | 500 | 280 | 2567 | 8.2 | 840~1400 |

| 600 | 350 | 2674 | 8.6 | 1050~1750 | |||

| TSH-95 | 93 | 32~68 | 500 | 450 | 4126 | 8.7 | 1350~2250 |

| 600 | 550 | 4202 | 8.9 | 1650~2750 | |||

| TSH-135 | 133 | 32~68 | 400 | 1000 | 11460 | 8.6 | 3000~5000 |

Links:https://www.globefindpro.com/products/79760.html

-

TSV-66 Extrusion Equipment

TSV-66 Extrusion Equipment

-

Standard LED Tube

Standard LED Tube

-

TSS-95 Extrusion Machine

TSS-95 Extrusion Machine

-

TM220W/TM320W Trailer Mounted VMS

TM220W/TM320W Trailer Mounted VMS

-

TSB-18 Screw Extruder

TSB-18 Screw Extruder

-

TM320H4C/TM400H4C/ TM400H5C Trailer Mounted VMS

TM320H4C/TM400H4C/ TM400H5C Trailer Mounted VMS

-

TSC-65/180 Screw Extruder

TSC-65/180 Screw Extruder

-

TSH-25 Screw Extruder

TSH-25 Screw Extruder

-

TSV-100 Extrusion Equipment

TSV-100 Extrusion Equipment

-

TSC-52/150 Screw Extruder

TSC-52/150 Screw Extruder

-

TSS-65 Extrusion Machine

TSS-65 Extrusion Machine

-

TSH-65 Screw Extruder

TSH-65 Screw Extruder