Tunnel Pasteurizer

Continuous spraying type tunnel pasteurizer is designed with 4-stage pasteurization process: circulating warm water for preheating, circulating hot water for pasteurization, circulating warm water for pre-cooling, and cooling water for spraying. The pasteurization equipment features automatically controlled pasteurization temperature and steplessly adjustable pasteurization time. It can be designed according to the pasteurization conditions and output provided by the clients.

The tunnel pasteurizer is suitable for the pasteurization and cooling of food, beverage and condiments packed in bottles, jars, cans, pouches or trays.

Technical parameters

| Model | PLS-1000 | PLS-2000 | PLS-3000 | PLS-5000 |

| Max. Pasteurization temperature | 100℃ | |||

| Pasteurization conveyor width | 1500mm | |||

| Conveyor speed | 110-553mm/min(stepless speed) | |||

| Steam pressure | 0.4MPa | |||

| Length of pasteurization section(mm) | 9000mm | 16000mm | 22000mm | 320000mm |

| Length of pre-cooling section(mm) | 1200mm | 16000mm | 1800mm | 2200mm |

| Length of cooling section(mm) | 3000mm | 5000mm | 8000mm | 10000mm |

| Hot water recycle capacity(m3) | 21m3 | 25 m3 | 35 m3 | 50 m3 |

| Power(kW) | 9.6kw | 10.6kw | 13.6kw | 16.5kw |

| Size(mm) | 9880mm | 17880mm | 23800mm | 34880mm |

| 2250mm | ||||

| 1735mm | ||||

Scan QR to Read

Links:https://www.globefindpro.com/products/7996.html

Links:https://www.globefindpro.com/products/7996.html

Recommended Products

-

Inline Homogenizer, TRL 2 Series

Inline Homogenizer, TRL 2 Series

-

Automatic Static Retort (Water Spray)

Automatic Static Retort (Water Spray)

-

Static Retort (Lateral Spraying & Pulsing Type)

Static Retort (Lateral Spraying & Pulsing Type)

-

ZnSe and GaAs Focus Lens (Laser Lens for Laser Machines)

ZnSe and GaAs Focus Lens (Laser Lens for Laser Machines)

-

Plastic Sheet Vacuum Forming Machine, XSH Series

Plastic Sheet Vacuum Forming Machine, XSH Series

-

Automatic Paper UV Varnishing Machine, SE-1200 (UV Coating Machine)

Automatic Paper UV Varnishing Machine, SE-1200 (UV Coating Machine)

-

Total Reflector (Reflective Laser Mirror for Laser Marking Machine, Laser Engraving Machine and Laser Cutting Machine)

Total Reflector (Reflective Laser Mirror for Laser Marking Machine, Laser Engraving Machine and Laser Cutting Machine)

-

Quartz Sand Filter

Quartz Sand Filter

-

Plastic Thermoforming Machine, RMC-600/400

Plastic Thermoforming Machine, RMC-600/400

-

Secondary RO Water Treatment

Secondary RO Water Treatment

-

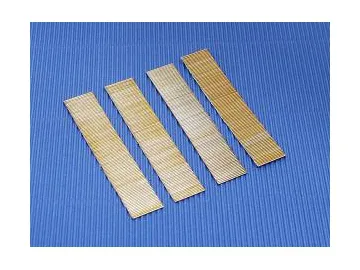

Pin Nails

Pin Nails

-

Solventless Film Lamination Machine

Solventless Film Lamination Machine

Hot Products