Oil Resistant Conveyor Belt

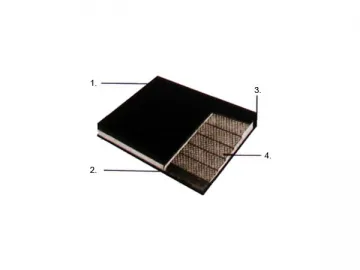

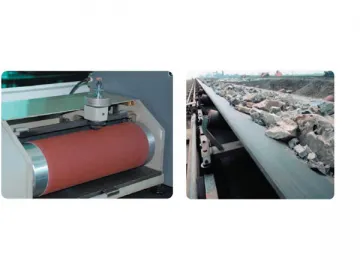

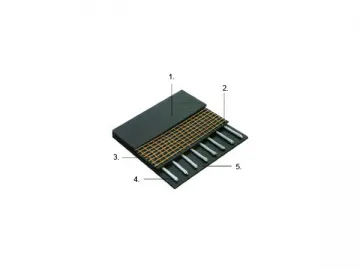

The oil resistant conveyor belt is a kind of industrial conveyor belting engineered from nitrile rubber. It is customizable to meet different application environment, according to clients' requirements. Its carcass materials are polyester canvas and EP canvas, so the oil and grease resistant conveyor belt is low in volume change rate and high in strength. Compared to other common rubber conveyor belts, this conveying belt has a longer service life as it is perfectly resistant to oil swelling.

Oil swells and corrodes rubber. Our oil resistant conveyor belt is specially designed to solve this problem. It is designed to convey mineral oil, vegetable oil, animal oil, hardware parts, household garbage, etc.

Features and Advantages of Oil Resistant Conveyor Belt

1. Excellent Oil Resistance

Nitrile rubber layer resists oil corrosion. We provide rubber layer of different grade oil resistance to suit diverse applications.

2. High Adhesive Strength Between Layers

Manufactured with excellent formula, the canvas layer not only comes with excellent oil resistance and high adhesive strength, also it won't be delaminated.

Parameters of Oil Resistant Conveyor Belt

| Rubber Type | Test Time | Normal Rubber | Ordinary Oil Resistant RubberOR101 | Medium Oil Resistant RubberOR102 | High Oil Resistant RubberOR103 | Compound Oil Resistant Rubber OHR/FOER | |

| 96Hr | 70% | 43% | 29% | -8% | -8% | ||

| 168Hr | 90% | 60% | 41% | -8% | -9% | ||

| Test Conditions | Test oil: No. 3 Oil (IRM x 903); Test Temperature: 70℃. | ||||||

| Rubber Type | Operating Temperature | Oil Type | |||||

| OR101 | -22℃ ~ 60℃ | Wood oil, frozen food oil, kerosene, etc. | |||||

| OR102 | -22℃ ~ 60℃ | Animal oil, vegetable oil, corn oil, etc. | |||||

| OR103 | -22℃ ~ 60℃ | Mineral oil, heavy oil, preservative oil, engine oil, animal oil, recycling oil, etc. | |||||

| OHR/FOER | -22℃ ~ 100℃ | Asphalt, coal, etc. | |||||

As an expert in industrial conveyor belts, we provide a great variety of special conveyor belting to handle the toughest conveying applications.

Links:https://www.globefindpro.com/products/80411.html

-

Standard Fire Resistant Conveyor Belt

Standard Fire Resistant Conveyor Belt

-

DAF Rear Wheel Bolt (DXE016)

DAF Rear Wheel Bolt (DXE016)

-

Chemical Resistant Conveyor Belt

Chemical Resistant Conveyor Belt

-

PVC Conveyor Belt

PVC Conveyor Belt

-

NN Conveyor Belt

NN Conveyor Belt

-

SHC1104 1k Bytes Contactless IC Card Chip

SHC1104 1k Bytes Contactless IC Card Chip

-

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

-

Abrasion Resistant Conveyor Belt

Abrasion Resistant Conveyor Belt

-

Fire Resistant Steel Cord Conveyor Belt

Fire Resistant Steel Cord Conveyor Belt

-

Special Rubber Sheet

Special Rubber Sheet

-

Ripstop Steel Cord Conveyor Belt

Ripstop Steel Cord Conveyor Belt

-

VOLVO Revolving Wheel Nut (DX0046)

VOLVO Revolving Wheel Nut (DX0046)