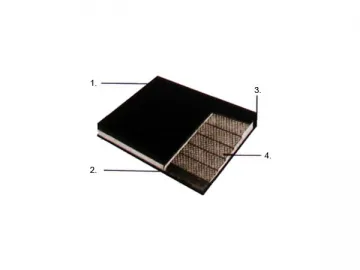

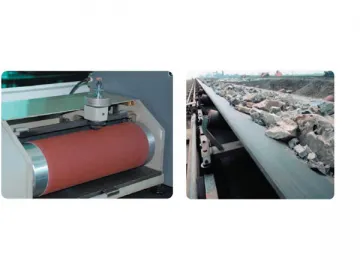

Chemical Resistant Conveyor Belt

Application

The chemical resistant conveyor belt is designed for acid-base working environments, for instance, fertilizer manufacturing factory, sea salt factory, chemical factory, etc. Therefore, if you are looking for fertilizer conveyor belt, salt conveyor belt, etc., then the chemical resistant conveying belt is the ideal one for you.

Features

1. This chemical resistant conveyor belt comes with corrosion resistant covering layer made of rubber and plastic. It is filled with acid and alkali resistant inert materials. Compared to neoprene rubber conveyor belt, it has better acid and alkali resistance.

2. Because of the carcass materials such as nylon or polyester canvas, the industrial belting not only features good flexibility and troughability, but also comes with low elongation.

Physical Performance of Covering Layer (Conditions for Hot Air to Speed Up Aging Test: 70℃×96h)

| Item | Tensile Strength/Mpa≥ | Elongation/%≥ | Abrasion/mm³≤ | Hardness/(°) 10-5 |

| Performance Before Aging | 14.0 | 400 | 250 | 60 |

| Performance After Aging | 12.0 | 340 | - | 65 |

Remark: When covering layer thickness is 0.8mmmm-1.6mm, thickness of samples could be the maximum cutting thickness. Under such condition, tensile strength and elongation could be maximally 15% lower than values in the table shown as below.

Chemical Resistance of Covering Layer

| Type (Performance before Aging) | Soak Solution | Concentration | Dipping Condition Temperature ×Time | Change Rate Before/After Dipping | |

| Volume Expansion Ratio | Change Rate of Strength | ||||

| A1 | Hydrochloric acid | 18% | 50℃×96h | Below 10% | Below -10% |

| A2 | Sulfuric acid | 50% | 50℃×96h | Below 10% | Below -10% |

| A3 | Sodium hydroxide | 48% | 50℃×96h | Below 10% | Below-10% |

Links:https://www.globefindpro.com/products/80414.html

-

PVC Conveyor Belt

PVC Conveyor Belt

-

NN Conveyor Belt

NN Conveyor Belt

-

SHC1104 1k Bytes Contactless IC Card Chip

SHC1104 1k Bytes Contactless IC Card Chip

-

Gloss Pigment Hot Stamping Foil

Gloss Pigment Hot Stamping Foil

-

Dolly Trailer

Dolly Trailer

-

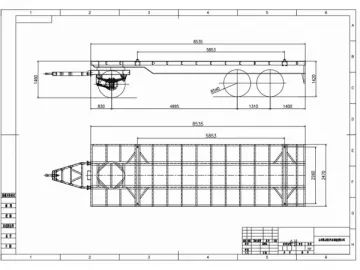

Timber Transport Semi Trailer

Timber Transport Semi Trailer

-

DAF Rear Wheel Bolt (DXE016)

DAF Rear Wheel Bolt (DXE016)

-

Standard Fire Resistant Conveyor Belt

Standard Fire Resistant Conveyor Belt

-

Oil Resistant Conveyor Belt

Oil Resistant Conveyor Belt

-

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

Mercedes-Benz Sonacome Rear Wheel Bolt (DXE008)

-

Abrasion Resistant Conveyor Belt

Abrasion Resistant Conveyor Belt

-

Fire Resistant Steel Cord Conveyor Belt

Fire Resistant Steel Cord Conveyor Belt