Truck-mounted Concrete Pump

Parameters of Concrete Pump

| Rated Capacity | 80/51m3 |

| Rated Output Pressure | 9.2/16MPa |

| Dia. of Cylinder ×Distance | Ф200×1800mm |

| Max. Conveying Height | 270m |

| Hydraulic System Pressure | 32MPa |

| Main Pump Output Capacity | 418L /min |

| Material Feeding Height | 1320mm |

| Power of Diesel Engine | 174KW |

| Exchange Time | 24 pcs /min |

| Rotational Speed | 2200r/min |

Parameters of Chassis

| Chassis Code | 1228272 |

| Model of Chassis | CA1123P9K2L4AE flat-head cargo vehicle chassis |

| Brand of Chassis | FAW |

| Outside Dimension(L×W×H) | 8128, 8628, 8928×2244×2558, 2718, 3108 |

| Emission Standards | GB3847-2005, GB17691-2005 ChinaIII |

| Discharge (ml)/Power(kw ) | 4040;4750;4750;4752/101;101;101;105 |

| Front Overhang/Rear Overhang(mm) | 1330/1998,1330/2498,1330/2598 |

| Max. Speed (km/h) | 96 |

| Model of Engine | BF4M2012-13E3;CA4DF3-13E3; CA4DF3-13E3U; CA4DF3-14E3F; |

Product Photos

Introduction

The concrete pump is mainly used on building, bridge, and tunnel construction projects. Presently available on the market are pumps with either gate valves or S-shaped valves, or installations that have their pumps mounted on a trailer chassis and powered by the motors therein.

Model HBC80C truck-mounted concrete pump uses the CTY5120THBDFL chassis to supply strong power for the concrete pumping operation. The vehicle is highly adaptable to various road conditions, and is especially capable of riding up steep slopes. Simply sit in the luxurious, air-conditioned cab with berth, and watch the pump coming into play.

This series of truck-mounted pumping system is available with the following features:

1. Original Swedish Volvo or Deutz industrial water-cooled inline 6-cylinder supercharger engine delivers a rated rotational speed of 2300r/min at a power of 174KW.

The Volvo brand is the symbol of reliability, technical innovation, industry-leading performance and long service life. Volvo engines should be ranked among top options for trailer-mounted pump manufacturers. Likewise, the Deutz engine is also a cost-effective choice for concrete pump car makers. Deutz products are often backed up by integrated services which guarantee product reliability.

Main pumps are sourced from Bosch Rexroth Company, available with an auxiliary pump for extra oil suction. Rexroth concrete pumps deliver high rotational speed and pressure while producing little noise. In addition to the digitalized stepless control of pump displacement, the pump also has the function of constant power regulation, which keeps the pump from overload when operating at the maximum capacity.

2. Eaton hydraulic concrete pumps have always been among the top options for larger concrete machinery manufacturers. Known for their minimum flow resistance and heat generation, Eaton pumps are often able to withstand high hydraulic pressure and deliver accurate, flexible pumping operations. Pipelines are sourced from Manuli Hydraulics, RIVAFLEX, and Aeroquip for high reliability.

3. Water deflector holes are added to the oil cylinder, which prevent water entering the oil cylinder.

4. The hydraulic system features hydraulically operated directional control technology. It completely relies on the hydraulic signal changes of the main oil cylinder and swinging oil cylinder to control the directions of oil flow.

Advantages of hydraulically operated directional control valve involve the following:

a. No PLC electrical elements are needed to control the pumping and valve swinging operations. Such a pumping and directional control system has a low failure rate, and is long-lasting and easier to control.

b. The whole system is comprised of only one main cylinder and one swinging cylinder. It does not require any constant pressure pumping system or power accumulator, and its water tank does not need any proximity switch. Its simplified structure is easy to maintain, and stable in directional control operations.

c. Simply hit a button to freely switch between high and low hydraulic pressures. There is no oil leak, which means no pollution to the surroundings. Damaged pistons can be automatically removed from the cylinder, which saves labor cost spent on piston replacement and reduces system downtime. To replace the piston, all you need to do is to hit a button and then watch the piston coming out into the water tank.

Links:https://www.globefindpro.com/products/80429.html

-

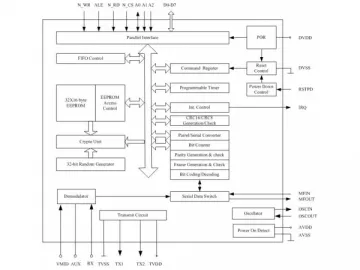

SHC1516 Online Transaction IC Card Chip

SHC1516 Online Transaction IC Card Chip

-

Customized Hot Stamping Foil

Customized Hot Stamping Foil

-

Drop Side Semi Trailer

Drop Side Semi Trailer

-

SHC1509 Contactless Card Reader Chip

SHC1509 Contactless Card Reader Chip

-

PVC Laminating Film for Furniture

PVC Laminating Film for Furniture

-

Flatbed Semi Trailer

Flatbed Semi Trailer

-

Stake Semi Trailer

Stake Semi Trailer

-

Metallic Hot Stamping Foil

Metallic Hot Stamping Foil

-

Concrete Pump

Concrete Pump

-

Concrete Mixer Truck

Concrete Mixer Truck

-

Box Semi Trailer

Box Semi Trailer

-

Trailer-Mounted Boom Concrete Pump

Trailer-Mounted Boom Concrete Pump