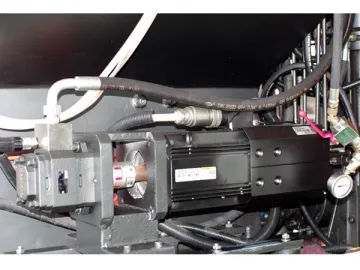

HZ Series Rubber Injection Molding Machine

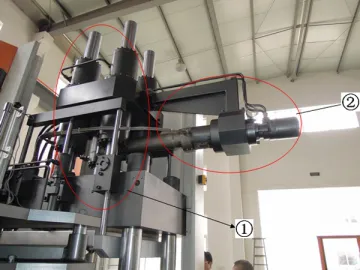

The HZ series rubber injection molding machine is provided with 2 types of injection units to meet the usage demands of different customers. One of them affords vertical material storing and vertical injecting, and the other is capable of horizontal material storing and vertical injecting.

Thanks to the design of horizontal material storing, the storing height is largely lowered and workers can directly stand on the floor to charge the raw materials into the material inlet without using the ladder. Meanwhile, the storing screw is completely detached from the injection ram, facilitating the operation. All in all, this rubber injection molding machine is perfect for customers requiring lowered feeding height.

① This injection unit enables material storing and injecting.

② For the horizontal material storing unit, the storing screw is separated from the injection ram, which effectively reduces material feeding height.

Horizontal injection unit with automatic demoulding system

Parameters

| Clamping Unit | |||||||

| Machine type | BE100 | BE160 | BE250 | BE400 | BE560 | ||

| Clamping force | kN | 1000 | 1600(1700) | 2500(2800) | 4000(4450) | 5000(5500) | |

| Opening force | kN | 38 | 58 | 58 | 93 | 94 | |

| Opening stroke | kN | 450 | 500 | 500 | 600 | 650 | |

| Max. opening between heating plates | mm | 500 | 600 | 650 | 780 | 850 | |

| Clamping speed | mm/sec | 420 | 420 | 400 | 430 | 435 | |

| Opening speed | mm/sec | 450 | 290 | 467 | 290 | 450 | |

| Lifting stroke (Stretching/retracting force) | mm(kN) | 250(24.5/14.5) | 250(40/24.5) | 250(62.8/38) | 400(98/58) | 400(98/58) | |

| Injection Unit | |||||||

| Max. injection volume | cm3 | 500 | 1000 | 2000 | 3300 | 4500 | |

| Max. injection pressure | bar | 2000 | 2130 | 2000/2200 | 2000/2240 | 2080 | |

| Max. injection capacity | cm3/sec | 60 | 80 | 135 | 135 | 205 | |

| Screw diameter | mm | 27 | 32 | 42 | 52 | 62 | |

| Screw length diameter ratio | L:D | 10:1 | 10:1 | 10:1 | 10:1 | 10:1 | |

| Max. speed/torque of screw | rpm/Nm | 220/380 | 250/540 | 213/1250 | 237/1372 | 150/1940 | |

| Plasticizing capacity | cm3/min | 400 | 600 | 1000 | 2000 | 2200 | |

| Number of heating zones | 1 | 3 | 3 | 3 | 3 | ||

| Hydraulic Unit | |||||||

| System pressure | bar | 250(280) | 250(280) | 250(280) | 250(280) | 250(280) | |

| Max. pump capacity (1450rmp) | L/min | 41 | 41 | 65 | 65 | 103 | |

| Tank volume | L | 100 | 150 | 200 | 300 | 500 | |

| Electrical Equipment | |||||||

| Motor Power | kW | 15 | 15 | 22 | 22 | 30 | |

| Heating capacity of plates | kW | 10.8 | 9.9 | 15.9 | 25.2 | 30.2 | |

| Controller voltage | V | 24 | 24 | 24 | 24 | 24 | |

| * Excluding additional mould heating | |||||||

| Mould Mounting Dimensions (mm) | |||||||

| A | Locating ring size | 80 | 110 | 110 | 110 | 110 | |

| C | Nozzle inner diameter | 4 | 4 | 6 | 8 | 8 | |

| D | Max. nozzle diameter | 6 | 6 | 10 | 12 | 12 | |

| E | Min. mould height | 50 | 100 | 150 | 180 | 200 | |

| E1 | Max. mould height | 250 | 300 | 350 | 400 | 600 | |

| F | Clear distance of columns(W) | 525 | 590 | 720 | 830 | 950 | |

| G | Clear distance of columns(L) | 270 | 295 | 380 | 600 | 710 | |

| H | Heating plate width | 360(450) | 500(570) | 600(670) | 710(810) | 810(910) | |

| I | Heating plate Length | 500(600) | 550(650) | 650(750) | 800(1200) | 1100(1300) | |

| T-slot bolt (mm) | |||||||

| Upper and bottom ejector | M12 | M12 | M12 | M16 | M16 | ||

| Heating platen | M12 | M16 | M16 | M16 | M16 | ||

| Machine Dimensions (mm) | |||||||

| A | Total height | 2840 | 2900 | 3309 | 3627 | 3980 | |

| G | Total length | 2000 | 2700 | 2700 | 3100 | 3660 | |

| N | Total width | 1120 | 1150 | 1200 | 1400 | 1680 | |

| Weight | |||||||

| Standard machines | Kg | 4100 | 5800 | 7500 | 14000 | 20000 | |

Related Names

Rubber Injection Molder | Industrial Injection Equipment | Horizontal Injection Moulding Machine

Links:https://www.globefindpro.com/products/80472.html

-

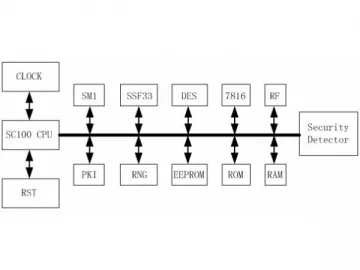

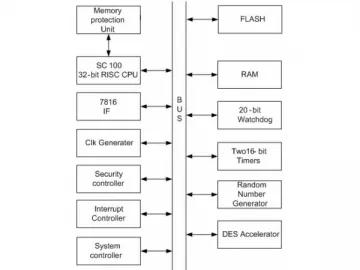

SHC1237 220k SIM Card Chip

SHC1237 220k SIM Card Chip

-

Mould for Auto Bush

Mould for Auto Bush

-

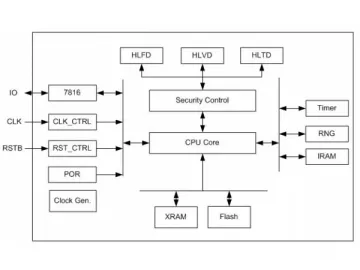

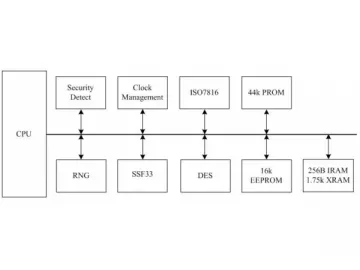

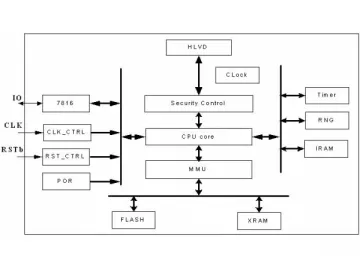

SHC1302F 32 Bit Dual Interface Credit Card Chip

SHC1302F 32 Bit Dual Interface Credit Card Chip

-

Mould for Silicone Rubber Products

Mould for Silicone Rubber Products

-

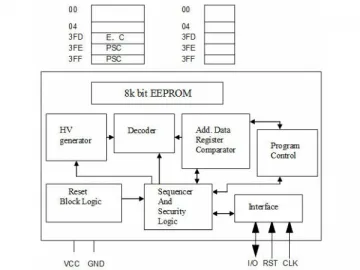

SHC2248 8k Bits EEPROM Contact Encryption Chip

SHC2248 8k Bits EEPROM Contact Encryption Chip

-

SHC1230 256k SIM Card Chip

SHC1230 256k SIM Card Chip

-

SHC2242 2k Bits EEPROM Contact Encryption Chip

SHC2242 2k Bits EEPROM Contact Encryption Chip

-

SE Series Rubber Injection Molding Machine

SE Series Rubber Injection Molding Machine

-

SHC1216 16k EEPROM Contact Social Security Card Chip

SHC1216 16k EEPROM Contact Social Security Card Chip

-

SHC1220S 140k SIM Card Chip

SHC1220S 140k SIM Card Chip

-

Mould for Home Appliance

Mould for Home Appliance

-

SHC1232 32k EEPROM Contact Social Security Card Chip

SHC1232 32k EEPROM Contact Social Security Card Chip