Sliding Plate System

The sliding plate system is usually used for manufacturing rubber products with bushing or mould base. Compared with manual handling, it saves more time and labors by performing one-time mould base fixing and automatic product shifting.

Working Principle

After the vulcanization and the opening of mould, the fixed mould ejector will eject the lower mould. Once the lower mould is shifted, the ejector plate will eject all products at one time. Thus automatic product shifting is achieved.

Mould shifting ejection system

Advantages

1. This sliding plate system enables 70% or 100% lower mould shifting, making for easy mould fixing and convenient automated product removal.

2. If you require 2 lower mould halves in this system, we also can make corresponding adjustment.

3. The shifting speed is available either in manual or hydraulic control.

4. The whole operation process is monitored, and the diagnosis and alarming system is configured.

5. The gear and rack linkage is adopted to guarantee the stability and reliability of the whole shifting mechanism during the operation.

Related Names

Die Mould Equipment | Multiple Cavity Mold System | Mould Transfer Machine

Links:https://www.globefindpro.com/products/80479.html

-

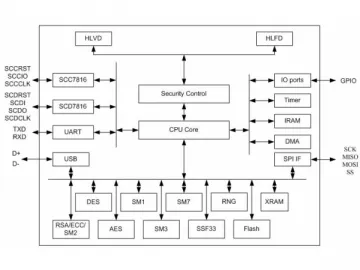

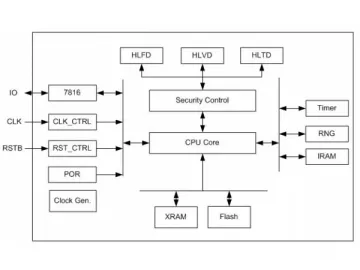

SHC1408S 256k Contact Flash USB KEY Chip

SHC1408S 256k Contact Flash USB KEY Chip

-

Seawater Desalination System (≥ 1000LPH)

Seawater Desalination System (≥ 1000LPH)

-

Bottle Washing Machine

Bottle Washing Machine

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Filling Machine

Bottle Filling Machine

-

Bottle Conveyor

Bottle Conveyor

-

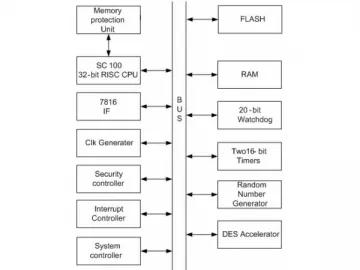

SHC1230 256k SIM Card Chip

SHC1230 256k SIM Card Chip

-

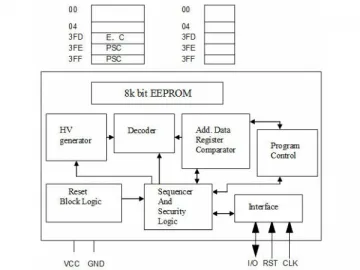

SHC2248 8k Bits EEPROM Contact Encryption Chip

SHC2248 8k Bits EEPROM Contact Encryption Chip

-

Mould for Silicone Rubber Products

Mould for Silicone Rubber Products

-

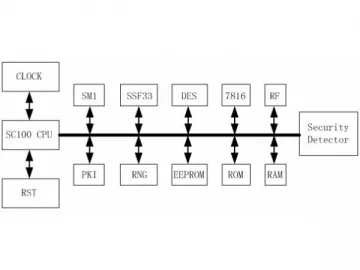

SHC1302F 32 Bit Dual Interface Credit Card Chip

SHC1302F 32 Bit Dual Interface Credit Card Chip

-

Mould for Auto Bush

Mould for Auto Bush

-

SHC1237 220k SIM Card Chip

SHC1237 220k SIM Card Chip