Seawater Desalination System (≥ 1000LPH)

The seawater desalination system is a large-scale reverse osmosis system with output above 1000L per hour. It is suited to islands, stations, and water deficient coastal cities. This reverse osmosis desalination system can change the marine water into national standard drinkable pure water, by using the reverse osmosis technology to remove harmful ingredients from seawater, for instance, inorganic salt, bacteria, germs, heavy metal ion, etc.

Pretreatment system of the whole set seawater desalination system employs the full-automatic multi-way combination valves, for the purpose of realizing the full automation of large-flow back washing & conventional well-flushing. Additionally, the reverse osmosis water system is durable with a new shell made of corrosion proof materials such as 316SS. Its main machine unit such as the RO water filter system is comprised of the most advanced RO system software and qualified membrane with high desalination rate. It is energy-efficient, because we have added the efficient unique energy recovery technology to this seawater desalination system according to the pure water output.

Apart from a world-class Danfoss high-pressure pump, the reverse osmosis seawater desalination system is also equipped with an advanced inspection and monitoring system to make sure the stable operation and high quality pure water output. Besides that, control instruments and discharging pipes keep the whole pipeline system running smoothly and safely.

Thus far, the reverse osmosis desalination plant with the output ranging from 1000L/H to 2000L/H is much more popular in the market. If you have any special requirements, please feel free to contact our sales engineers. We can customize the products according to your requirements.

The seawater desalination system has been sold all over the world, including Indonesia, Ghana, Saudi Arabia, Egypt, Iran, etc.

Features

The large-scale reverse osmosis seawater desalination system applies the following high quality parts.

1. Imported PLC control

2. Dual-phase steel imported from Denmark

3. 2507 Danfoss high-pressure pump

4. Dow seawater RO membrane 8040

5. Stainless steel 316 high pressure pipeline

6. 1000PSI Reverse osmosis membrane shell and perfect dosing system for pure water of WHO drinking water standards

| Model | SWRO-20 | SWRO-25 | SWRO-30 | SWRO-40 | SWRO-50 | SWRO-60 | |

| Performance | Pure water production | 1M3/H (20M3/D) | 1.25M3/H (25M3/D) | 1.5M3/H (30M3/D) | 2M3/H (40M3/D) | 2.5M3/H (50M3/D) | 3M3/H (60M3/D) |

| Main RO skin dimension for reference (M) | 3.0×1.0×2.0 | 3.0×1.0×2.0 | 3.0×1.0×2.0 | 4.0×1.5×2.0 | 4.0×1.5×2.0 | 5.0×2.0×2.0 | |

| Weight for reference (KG) | 1000 | 1250 | 1500 | 3000 | 3500 | 4000 | |

| Main HP Pump Power Loading (KW) | 7.5 | 7.5 | 11 | 11 | 15 | 15 | |

Working Principle

This reverse osmosis seawater desalination system needs a good pretreatment system to ensure good water output quality. It is known that seawater has higher hardness as well as contains higher total dissolved solids and other impurities. During the operation, the reverse osmosis system is sensitive to turbidity, temperature, hardness, PH value, chemical substances, etc. As a result, the seawater desalination system has higher requirements toward inlet water. The poorer the inlet water quality is, the lower the water production rate will be. Prior to entering the reverse osmosis membrane device, seawater must be pretreated. The followings are the descriptions about the commonly used seawater desalination pretreatment technologies.

a. Germicide and Algaecide

A large amount of microorganisms, bacteria, and algae exists in seawater. Their propagation and growth will directly affect the smooth, normal operation of seawater desalination system and process pipeline. Most desalination projects use liquid chlorine, sodium hypochlorite, copper sulfate, or other chemical agents to kill bacteria and algae.

b. Coagulation and Filtration

Since seawater rises or falls periodically, it contains a large amount of sand and its turbidity changes greatly, resulting in the unstable operation of the pretreatment system. During the pretreatment, coagulation and filtration are added to decrease the turbidity through removing the colloid, impurities from seawater.

Generally, the RO seawater desalination system uses Silting Density Index(SDI). SDI of the seawater that will get into the RO device should be below 4. Seawater comes with higher specific gravity, higher PH value, and larger seasonal temperature change. Therefore, ferric trichloride is frequently used as the coagulant. It is free from temperature influence, and has fast sedimentation speed.

c. Filter

To further improve the pure water quality and lower the inlet water turbidity, a sand filter is used after the coagulation filtration. It can remove tiny suspended solids and particles from water.

d. Scale Inhibitor and Reducing Agent

For the sake of smooth operation of reverse osmosis system, a scale inhibitor is required. It should be selected according to the water quality. In addition, an oxidizing agent has been added into the pretreatment for sterilization. As a consequence, we need to add a reducing agent into the seawater inflow, so that the residual chlorine contained in the marine water could be smaller than 0.1ppm ( or ORP<200mV).

e. Cartridge Filter

The seawater desalination system is designed with a 316L cartridge filter, aperture of which is 5μm. It filters out at least Φ5μm particles or impurities from the seawater that later gets into the high-pressure pump. Aside from the high-pressure pump, it also keeps the long-term smooth operation of both energy recovery device and RO membrane element.

f. High-pressure Pump and Energy Recovery Device

Both high-pressure pump and energy recovery device are important equipment utilized to provide energy conversion and save energy, respectively. The energy recovery device can make full use of the reverse osmosis concentrated seawater discharging pressure to increase the reverse osmosis inlet water pressure by 30%. And the concentrated seawater can be thereby utilized efficiently while minimizing the energy consumption. Also, the operation cost will be effectively cut down. We apply the world's best Danfoss high pressure pump.

g. RO Element and Device

The reverse osmosis membrane element is the core part of reverse osmosis seawater desalination system. We use SW30-4040 or 8040 RO membrane manufactured by DOW filmtec Company. This RO membrane is characterized by high desalination rate as well as good resistance to pressure, oxidization, and pollution. High pressure part of the equipment should be made of stainless steel of at least 316L, thus preventing high-pressure pipeline from seawater corrosion.

h. Control System

The whole seawater desalination system adopts the programmable logic controllers to form a control system which is comprised of the dispersed sampling control and centralized monitoring operation. A high and low pressure protection switch has been set according to the technological parameters. It is an automatic transfer switch that can realize the automatic switchover and automatic alarming or stop when the conductivity, current or pressure is abnormal. That means it can safeguard the high-pressure pump and reverse osmosis membrane element.

The high-pressure pump starts and stops under the function of the frequency conversion control. Such control method not only helps save energy, but also helps prevent the high-pressure pump and membranes from being damaged. It automatically realizes the low pressure automatic flushing. Especially when the reverse osmosis seawater desalination system stops working and sediments occurs, it automatically uses low pressure desalinated water to swap out the concentrated seawater which will pollute the membranes. In addition, the control system displays and stores the water temperature, water flow, water quality, water output, etc. A clear, dynamic monitoring system is used for the operation. All in all, the entire control system simplifies the manual operation, and ensures the reverse osmosis system for seawater desalination operates automatically, safely, and reliably.

Links:https://www.globefindpro.com/products/80482.html

-

Bottle Washing Machine

Bottle Washing Machine

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Filling Machine

Bottle Filling Machine

-

Bottle Conveyor

Bottle Conveyor

-

Semi-automatic Bottle Filling Line

Semi-automatic Bottle Filling Line

-

Ice Vending Machine

Ice Vending Machine

-

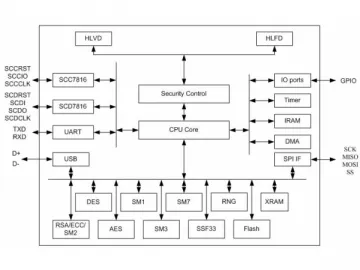

SHC1408S 256k Contact Flash USB KEY Chip

SHC1408S 256k Contact Flash USB KEY Chip

-

Sliding Plate System

Sliding Plate System

-

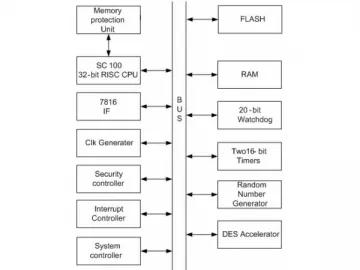

SHC1230 256k SIM Card Chip

SHC1230 256k SIM Card Chip

-

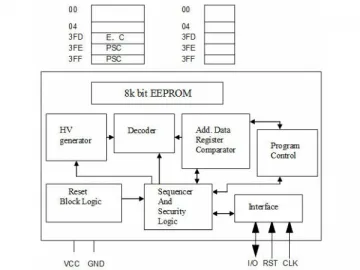

SHC2248 8k Bits EEPROM Contact Encryption Chip

SHC2248 8k Bits EEPROM Contact Encryption Chip

-

Mould for Silicone Rubber Products

Mould for Silicone Rubber Products

-

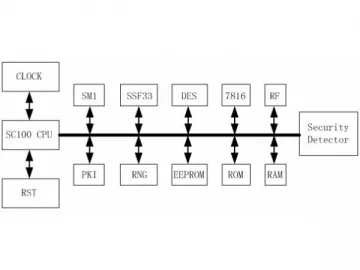

SHC1302F 32 Bit Dual Interface Credit Card Chip

SHC1302F 32 Bit Dual Interface Credit Card Chip