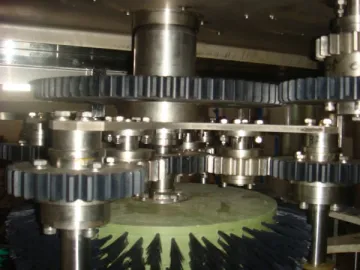

Bottle Washing Machine

The bottle washing machine is a key component of our bottled water plants. It differs from a bottle rinsing machine in that it is primarily used to clean the inner side of 5 gallon water bottles. This bottling equipment mainly consists of the rack, chain conveyor, flushing pipeline, water tank, bottle dropping mechanism, etc.

Construction Features of the Bottle Washing Machine

1. Rack

Rack of the bottle washing machine is welded from 75x45 stainless steel square tube. It is featured by high strength, good rigidity, light weight, beautiful appearance, and easy cleaning. The rack is welded with the automatic bottles loading mechanism.

2. Chain Conveyor

The bottle washer applies the chain conveyor formed by the driven chain wheel, chain, bottles supporting rack, bottles fixing device, etc. Both chain and chain wheel are meticulously designed.

a. Main Transmission

Due to variable frequency control, the bottle washing machine makes sure that bottles can stay on each position for a fixed time. The chain plate position has been strictly calculated to make sure the accurate, automatic positioning of the whole bottle washing system.

b. Adjustment

The chain conveyor can be adjusted by the bearing bolt on its end.

3. Flushing Pipeline

Flushing pipeline of the bottle washing machine is made of stainless steel tube. We adopt the special rotary screw nozzle which allows for excellent cleaning effect. Here below are the cleaning positions.

This bottle washing machine has 12 flushing processes. A dip drying position is set before the alkali liquor washing process, and two dip drying positions are separately set after the medicine washing and bottled product washing processes. The drying time is 18 seconds.

When the bottle washing machine is connected to the power supply, the PLC control system will control the contactor for making all the water pumps start working. Then the signals will be sent to a transducer. This transducer starts the conveyer chains. At this time, the bottle washing equipment will deliver the bottle to each process for flushing. Both flushing time and alkali liquor temperature can be adjusted via a touch screen. Once the flushing is over, the bottles will get back to the chain conveyor.

4. Water Tank

Our line of bottle washing machine for 5 gallon water bottles is available with four tanks, namely one alkali liquor tank, two liquid medicine tanks, and one backflow water tank. Every tank has a charging bucket with filter screen. You can clean the water tank through the bucket. When the bottle washing machine is running, you can clean and replace the water tank without affecting the normal operation of the whole equipment. The water level of the tanks can be monitored through the bucket cover which is made of organic glass.

The water tank is set with a low liquid level alarming device. When there are too much water, it can be overflowed via a outlet. A temperature controlled heater is installed to the alkali liquid tank. On the bottom of each water tank, there is a outlet for discharging mixed water. Inside the rack, no water tank is set for finished water. Outside finished water directly gets into the water pumps.

All the outlets of the water pumps have reversing valves. When the bottle washing machine doesn't work, the water will get back to its own water tank via the reversing valves. Frequent restarting of water pumps can be thereby avoided. Also, the service life of the water pump can be prolonged as well.

5. Bottle Dropping Mechanism

The bottle washing machine has a bottle dropping mechanism composed of bottles supporting bucket, bottles laying rack, cylinder, etc. If all the bottles have been washed, they will directly drop to the chain conveyor through the bottle dropping mechanism.

Links:https://www.globefindpro.com/products/80483.html

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Filling Machine

Bottle Filling Machine

-

Bottle Conveyor

Bottle Conveyor

-

Semi-automatic Bottle Filling Line

Semi-automatic Bottle Filling Line

-

Ice Vending Machine

Ice Vending Machine

-

Bottle Rinsing Machine

Bottle Rinsing Machine

-

Seawater Desalination System (≥ 1000LPH)

Seawater Desalination System (≥ 1000LPH)

-

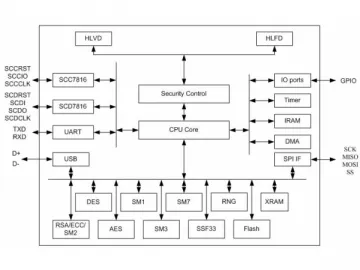

SHC1408S 256k Contact Flash USB KEY Chip

SHC1408S 256k Contact Flash USB KEY Chip

-

Sliding Plate System

Sliding Plate System

-

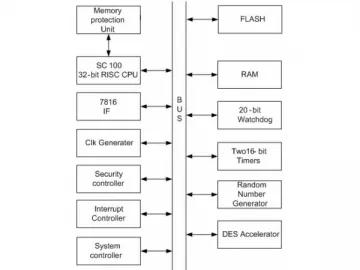

SHC1230 256k SIM Card Chip

SHC1230 256k SIM Card Chip

-

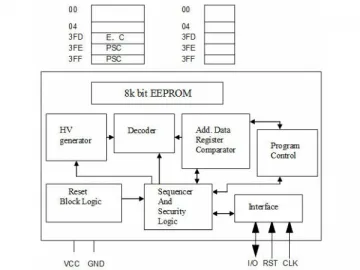

SHC2248 8k Bits EEPROM Contact Encryption Chip

SHC2248 8k Bits EEPROM Contact Encryption Chip

-

Mould for Silicone Rubber Products

Mould for Silicone Rubber Products