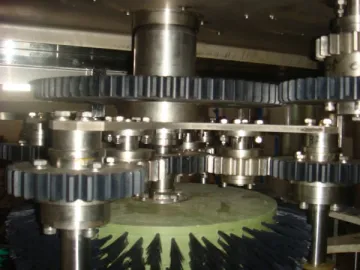

Bottle Filling Machine

The bottle filling machine is the most important part of our 5 gallon filling line. It is a rotary filler for bottled water production. It is mainly made of the main transmission unit, filling unit, and the start wheel for bottle loading and unloading. The filling unit of the liquid filling machine consists of the water feeding device, filling buckets, filling valves, and so forth.

Working Principle of the Bottle Filling Machine

This bottled water filling machine makes use of the micro-pressure filling. It uses a water pump to supply water to the filling bucket which should be full during the whole filling process. A pressure sensor is set to the top of the filling bucket. Signals are sent to the transducer via this pressure sensor. Then, the transducer will control the rotation speed of the water pump motor, so as to ensure the constant filling pressure.

Bottles will be fed to the bottle filling machine by the star wheel. Once they arrive at the filling area, they will be lifted up by a roller. The filling valves start to fill the bottles. When the bottles get to the end of the filling area, they will get to the cam lower part along with the roller. Under such condition, the filling valves will automatically shut down. Those filled bottles will be sent out by the star wheels.

Star Wheel AdjustmentStar Wheel Transmission

The start wheel is a key component of the bottle filling machine, and functions to load and unload the water bottles. The distance between the star wheel and shaped plate adapts to the filling bucket diameter. The maximum diameter is 3mm. If the star wheels don't work synchronously, you need to loosen the bolts on the middle part of the axle. After you have adjusted the star wheels, screw down the bolts.

Links:https://www.globefindpro.com/products/80485.html

-

Bottle Conveyor

Bottle Conveyor

-

Semi-automatic Bottle Filling Line

Semi-automatic Bottle Filling Line

-

Ice Vending Machine

Ice Vending Machine

-

Bottle Rinsing Machine

Bottle Rinsing Machine

-

Industrial Reverse Osmosis System (300LPH)

Industrial Reverse Osmosis System (300LPH)

-

Seawater Desalination System (

Seawater Desalination System (

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Washing Machine

Bottle Washing Machine

-

Seawater Desalination System (≥ 1000LPH)

Seawater Desalination System (≥ 1000LPH)

-

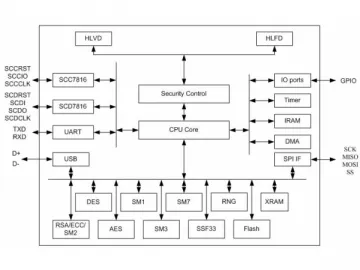

SHC1408S 256k Contact Flash USB KEY Chip

SHC1408S 256k Contact Flash USB KEY Chip

-

Sliding Plate System

Sliding Plate System

-

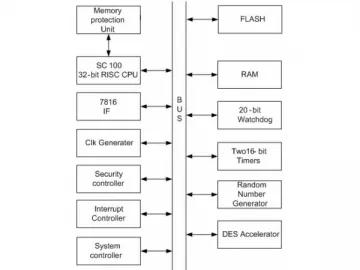

SHC1230 256k SIM Card Chip

SHC1230 256k SIM Card Chip