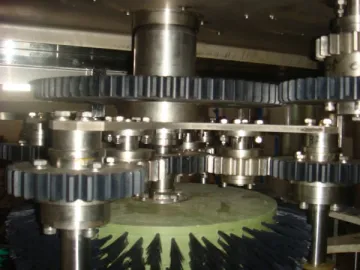

Semi-automatic Bottle Filling Line

The semi-automatic bottle filling line consists of turnover type bottle washing machine, atmospheric-pressure bottle filling machine, bottle capping machine, and conveyor system. It can be automatically adjusted for different size bottles. The stream line operation is extremely suitable for large bottles with threads. Additionally, this bottle filling line features reliable, easy operation. All the electrical parts are of well-known brands.

Applicable Fields

This bottle filling line is a split type liquid filling line that is suitable for filling bottled water, wines, fruit juice, carbonated beverage, etc. Made of stainless steel, it is clean and hygienic.

a. bottled water factory

b. Bottle fruit juice factory

c. Bottled carbonated beverage factory

Features

1. The semi-automatic bottle filling line needs low cost and offers high output.

2. Made with the old design, it works stably.

| Output | 2000-2500 bottles/hour (500ml) |

| Specifications of Suited Bottles | Diameter of Bottle Neck: Φ22mmDiameter of Bottle Body: Φ50-Φ100mmBottle Height: 160-320mm |

QS-12 Automatic Bottle Washing Machine

| Overall Dimensions | 1000×800×1800 |

| Power | 1.1 KW |

| Weight | 300Kg |

Atmospheric-pressure Liquid Filling Machine

| Overall Dimensions | 1020*800*1800 |

| Power | 1.5KW |

| Weight | 350Kg |

Bottle Capping Machine

| Overall Dimensions | 1020*800*1800 |

| Power | 1.5KW |

| Weight | 350Kg |

All the above bottling equipment that will contact with water are made of qualified 304 stainless steel. The special pump and electric motor are made in the south of China. AirTAC cylinder is applied. All the other electrical parts are Siemens brand.

Links:https://www.globefindpro.com/products/80487.html

-

Ice Vending Machine

Ice Vending Machine

-

Bottle Rinsing Machine

Bottle Rinsing Machine

-

Industrial Reverse Osmosis System (300LPH)

Industrial Reverse Osmosis System (300LPH)

-

Seawater Desalination System (

Seawater Desalination System (

-

Industrial Reverse Osmosis System (6000LPH)

Industrial Reverse Osmosis System (6000LPH)

-

Bottle Loading Machine

Bottle Loading Machine

-

Bottle Conveyor

Bottle Conveyor

-

Bottle Filling Machine

Bottle Filling Machine

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Washing Machine

Bottle Washing Machine

-

Seawater Desalination System (≥ 1000LPH)

Seawater Desalination System (≥ 1000LPH)

-

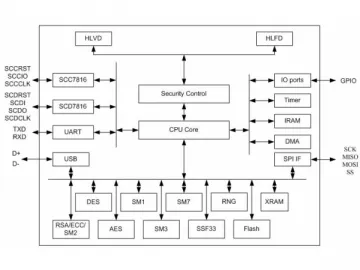

SHC1408S 256k Contact Flash USB KEY Chip

SHC1408S 256k Contact Flash USB KEY Chip