Bottle Rinsing Machine

As one of the parts of our 5 gallon water bottling plant, the bottle decapper is a heavy-duty bottle cap remover designed to remove the cap of 5 gallon water bottles. It comes with all stainless steel structure to ensure a lifetime of service.

The bottle decapper is made up of decapping head, bottle pressing rod, rack, cylinder, etc. It is compact in structure, and features beautiful appearance, easy operation, and reliable performance. This cap removing machine stops working when there no bottles. Besides that, it is controlled by a Panasonic PLC control system. The bottle decapper consumes less power.

Working Principle

The empty bottles are automatically delivered to the bottle decapping machine, after they have been placed on the chain conveyor system. The deThe bottle rinsing machine is a rotary rinsing system designed to cleaning the external body of 5 gallon water bottles before water filling. It is one of the components of our 5 gallon bottled water production line.

Features

1. The bottle rinsing machine automatically stops working when there are no bottles, so it can effectively save the energy.

2. Its circulation tank is added with a charging bucket. The charging bucket has a filter screen which can be cleaned or replaced.

3. Washing liquid tank of this bottle cleaning machine is installed with a 6KW electric heater, temperature control device, and a low-level liquid alarming device. Two positions are used for alkali liquor and bottled product washing, respectively.

4. The bottle rinsing machine applies the frequency control, which is used to adjust the operating speed according to the output per shift.

Construction

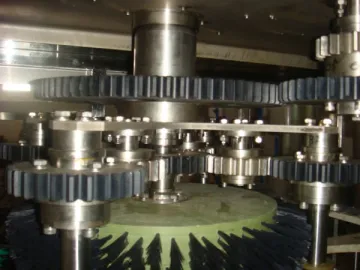

The bottle cleaning equipment is made up of the rack, main transmission, shaped plate, bottom brushing parts, tensioning device, central transmission part 1, central transmission part 2, bottles protecting device, flushing pipelines, etc.

Working Principle of the Bottle Rinsing Machine

The empty bottles gets into the bottle rinsing system via the bottles feeding wheels. A central brush will clean the bottles, and 4 side brushes will assist the central brush to clean the bottles' bodies. Another 4 specially designed bottom brushes mainly wash the bottom parts of the bottles.

The synchronous revolution and rotation of four side brushes and central brush, will driven the revolution and rotation of bottles. Therefore, the bottle rinsing machine can effectively clean dirties. Neither marks nor labels on the bottles will be damaged. Additionally, the synchronous rotation between the four bottom brushes and one central brushes ensures that all the dirties on the bottom part can be eliminated with effect. The detergent will be heated and then spayed onto the bottles for thorough cleaning. At the end, those bottles will be flushed with clean water.capper automatically removes the caps.

Links:https://www.globefindpro.com/products/80490.html

-

Industrial Reverse Osmosis System (300LPH)

Industrial Reverse Osmosis System (300LPH)

-

Seawater Desalination System (

Seawater Desalination System (

-

Industrial Reverse Osmosis System (6000LPH)

Industrial Reverse Osmosis System (6000LPH)

-

Bottle Loading Machine

Bottle Loading Machine

-

Shrink Wrap Machine

Shrink Wrap Machine

-

Industrial Reverse Osmosis System (5000LPH)

Industrial Reverse Osmosis System (5000LPH)

-

Ice Vending Machine

Ice Vending Machine

-

Semi-automatic Bottle Filling Line

Semi-automatic Bottle Filling Line

-

Bottle Conveyor

Bottle Conveyor

-

Bottle Filling Machine

Bottle Filling Machine

-

Pneumatic Cap Elevator

Pneumatic Cap Elevator

-

Bottle Washing Machine

Bottle Washing Machine