Shrink Wrap Machine

The semi-automatic or full-automatic shrink wrap machine is a piece of commonly used packaging equipment that employs PE film for shrink packaging of bottled water and beverage. This shrink wrapping machinery has such three functions as film cutting, film covering, and film shrinking.

Features

1. The shrink wrap machine is characterized by low cost, beautiful appearance, and stable operation. The films it used are cheaper than cartons.

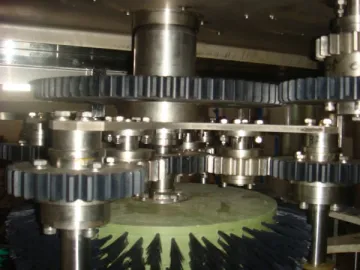

2. Its speed is adjusted by a frequency converter. A secondary bottle conveying device is used.

3. The shrink wrapper is pneumatically controlled to complete the bottle pushing as well as hot sealing and cutting. A inductive switch is used to control the film length.

4. Both touch screen and PLC control system are employed to greatly enhance the reliability of the equipment operation.

5. This shrink wrap machine applies the dual circulation air fan to make sure the uniform temperature of the shrink oven.

6. It has a cooling system which offers large air volume. The large amount of air volume guarantees the quick shaping.

7. Teflon glass fiber conveyor belt of the shrink wrapping machine is resistant to high temperature and abrasion. It delivers the bottles smoothly.

8. The delivery speed is regulated via a frequency stepless governor. Height of conveyor belt can be made according to the users' requirements. The adjustable range is ±50mm.

9. According to application requirements, the bottle conveyor for the heat shrink wrap machine can be lengthened or shortened accordingly. Wing-shaped stainless iron heating system can be used for a long time.

10. There is a goods loading device for the short production pause. The device ensures the continuous operation of the production line.

The shrink wrap machine has been successfully exported to Saudi Arabia, Yemen, Iraq, Libya, Liberia, Mali, Ghana, Nigeria, South Sudan, Cameroon, Gabon, Congo, Uganda, Ethiopia, Somalia, Kenya, Tanzania, Angola, and Zambia.

Parameters| Model | BZJ-5038B(Pneumatic) |

| Max. Packing Dimension | 450X270X350mm |

| Mini. Packing Dimension | 250X60X60mm |

| Voltage | 220V~240V,50~60HZ |

| Power | 1.5KW |

| Capacity | 0-6PACKING/MINUTE |

| Sealing Time | 0.5-1.5S |

| Conveyor Loading | 25KG |

| Width/Thickness of the Film | Max.550mm/0.03-0.25mm |

| Machine Size | 1020X830X1980 |

| Weight | 225KG |

| Shrink Film | PE, POF, PVC, PP |

Details

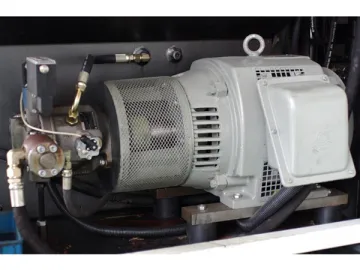

Through many times of improvement, our shrink wrap machine is innovatively designed with a plastic base for membrane cutting, which makes the bottles delivery smoother. The photoelectric sensor design allows for accurate film cutting. AirTAC cylinder runs stably and can be used for a long time.

A 3 to 5 meters long oven contributes to the optimal shrinking effect. The heating tube is more efficient with lower electricity consumption. Additionally, the final platform design offers the good cushioning effect for the whole shrink wrap machine.

With Omron touch screen design, the shrink wrapper is convenient and simple in operation.

The shrink wrapping equipment applies DELIXI breaker and Omron relay. The electrical system is stable and has a long service life.

Application

Links:https://www.globefindpro.com/products/80498.html

-

Industrial Reverse Osmosis System (5000LPH)

Industrial Reverse Osmosis System (5000LPH)

-

Auto Bottle Lifting Machine

Auto Bottle Lifting Machine

-

Industrial Reverse Osmosis System (700LPH)

Industrial Reverse Osmosis System (700LPH)

-

Industrial Reverse Osmosis System (20000LPH)

Industrial Reverse Osmosis System (20000LPH)

-

3 in 1 Automatic Bottle Filling Machine

3 in 1 Automatic Bottle Filling Machine

-

BE Series Rubber Injection Molding Machine

BE Series Rubber Injection Molding Machine

-

Bottle Loading Machine

Bottle Loading Machine

-

Industrial Reverse Osmosis System (6000LPH)

Industrial Reverse Osmosis System (6000LPH)

-

Seawater Desalination System (

Seawater Desalination System (

-

Industrial Reverse Osmosis System (300LPH)

Industrial Reverse Osmosis System (300LPH)

-

Bottle Rinsing Machine

Bottle Rinsing Machine

-

Ice Vending Machine

Ice Vending Machine