3 in 1 Automatic Bottle Filling Machine

The 3 in 1 automatic bottle filling machine is constituted by the bottle washer, bottle filler, bottle capper, and the conveyor system. It is extremely ideal for big bottles with threads. The multifunction liquid filling machine comes with reliable operation and simple operation. Its electric components are those of noted brands.

This 3 in 1 automatic bottle filling machine is the optimal bottling line for the production of water, fruit juice, and carbonated beverage. There are three different models for filling different liquids. We have constant temperature filling type, hot filling type, and constant pressure type bottle filling lines.

This 3 in 1 bottle filling machine is designed for:

1. The clients who want to build up the bottled water factory, fruit juice factory, and carbonated drinks factory.

2. The clients who want to improve their small or semi-automatic production line of water, fruit juice, or carbonated beverage.

Features

1. This 3 in 1 automatic bottle filling machine is precisely designed to minimize the intervals between the impellers, thereby preventing the bottles from getting stuck.

2. The special 3 in 1 design makes the bottling equipment operate more stably.

3. All the parts that will contact with water are made of stainless steel. The grade of the whole liquid filling line is thereby improved.

Bottle washing machine, one of the key parts of the 3 in 1 automatic bottle filling machine, applies high grade 304 stainless steel to avoid the rust. Domestic advanced high pressure pipeline are used to ensure the sufficient pressure for bottle washing. The bottle clamping thickness reaches 5mm, making the bottle clamping more stable.

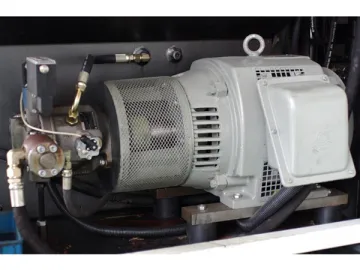

The multifunctional bottle filling machine employs high pure stainless steel to make the cylinder. The spring in the filling head is flexible enough to guarantee the filling speed. In addition, the materials feeding tube is clean, for being made of food grade stainless steel.

The capped head is made of high pure 304 stainless steel for preventing rust. Gear ring of the capper is designed according to the cap size. For that reason, the bottle cap won't be damaged when being clamped tightly.

A Taiwan Weinview touch screen is applied for convenient and simple operation. Moreover, the materials of the machine outer frame is 304 stainless steel as well..

Angel 3 in 1 automatic bottle filling machine is well accepted globally. Those clients are separately from Ghana, Nigeria, south Sudan, Cameroon, Gabon, Congo, Uganda, Ethiopia, Somalia, Kenya, Tanzania, Angola, and Zambia

Parameters of the Bottle Filling Line

| Model | CGF12125 | CGF18186 | CGF24248 | CGF323210 | CGF404012 | CGF505012 | CGF606015 | CGF808020 |

| No. of Washing, Filling and Capping Heads | 12-16-6 | 18-18-6 | 24-24-8 | 32-32-10 | 40-40-12 | 50-50-12 | 60-60-15 | 80-80-20 |

| Production Capacity(600ml) (B/H) | 2000- 4000 | 5000- 7000 | 8000-12000 | 12000-15000 | 16000-20000 | 20000-24000 | 25000-30000 | 35000-40000 |

| Suitable Bottle Specification(mm) | φ=50-110=170 330-2250ml | |||||||

| Washing Pressure(kg/cm2) | 2-3 | |||||||

| Motor Power (Kw) | Main motor 2.2kw | Main motor 2.2kw | Main motor 3kw | Main motor 5.5kw | Main motor 7.5kw | Main motor 11kw | Main motor 15kw | Main motor 19kw |

| Overall Dimensions (mm) | 2400× 1650 ×2500 | 2600× 1920 ×2550 | 3100× 2300 ×2800 | 3800× 2800 ×2900 | 4600× 2800 ×2900 | 5450× 3300 ×2900 | 6500× 4500 ×2900 | 76800×66400 ×2850 |

| Weight (kg) | 2500 | 3500 | 4500 | 6500 | 8500 | 9800 | 12800 | 15000 |

Links:https://www.globefindpro.com/products/80505.html

-

BE Series Rubber Injection Molding Machine

BE Series Rubber Injection Molding Machine

-

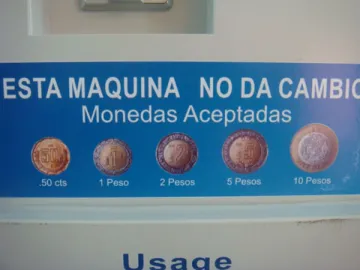

Water Vending Machine

Water Vending Machine

-

Bottle Labeling Machine

Bottle Labeling Machine

-

Mould for Anti-vibration Mount

Mould for Anti-vibration Mount

-

Bottle Decapper

Bottle Decapper

-

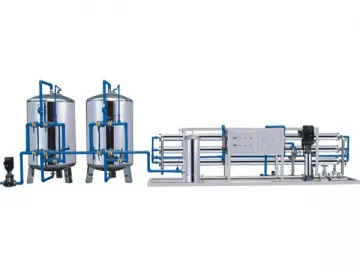

Industrial Reverse Osmosis System (15000LPH)

Industrial Reverse Osmosis System (15000LPH)

-

Industrial Reverse Osmosis System (20000LPH)

Industrial Reverse Osmosis System (20000LPH)

-

Industrial Reverse Osmosis System (700LPH)

Industrial Reverse Osmosis System (700LPH)

-

Auto Bottle Lifting Machine

Auto Bottle Lifting Machine

-

Industrial Reverse Osmosis System (5000LPH)

Industrial Reverse Osmosis System (5000LPH)

-

Shrink Wrap Machine

Shrink Wrap Machine

-

Bottle Loading Machine

Bottle Loading Machine